Adjustments

Adjusting Carriage Bearings

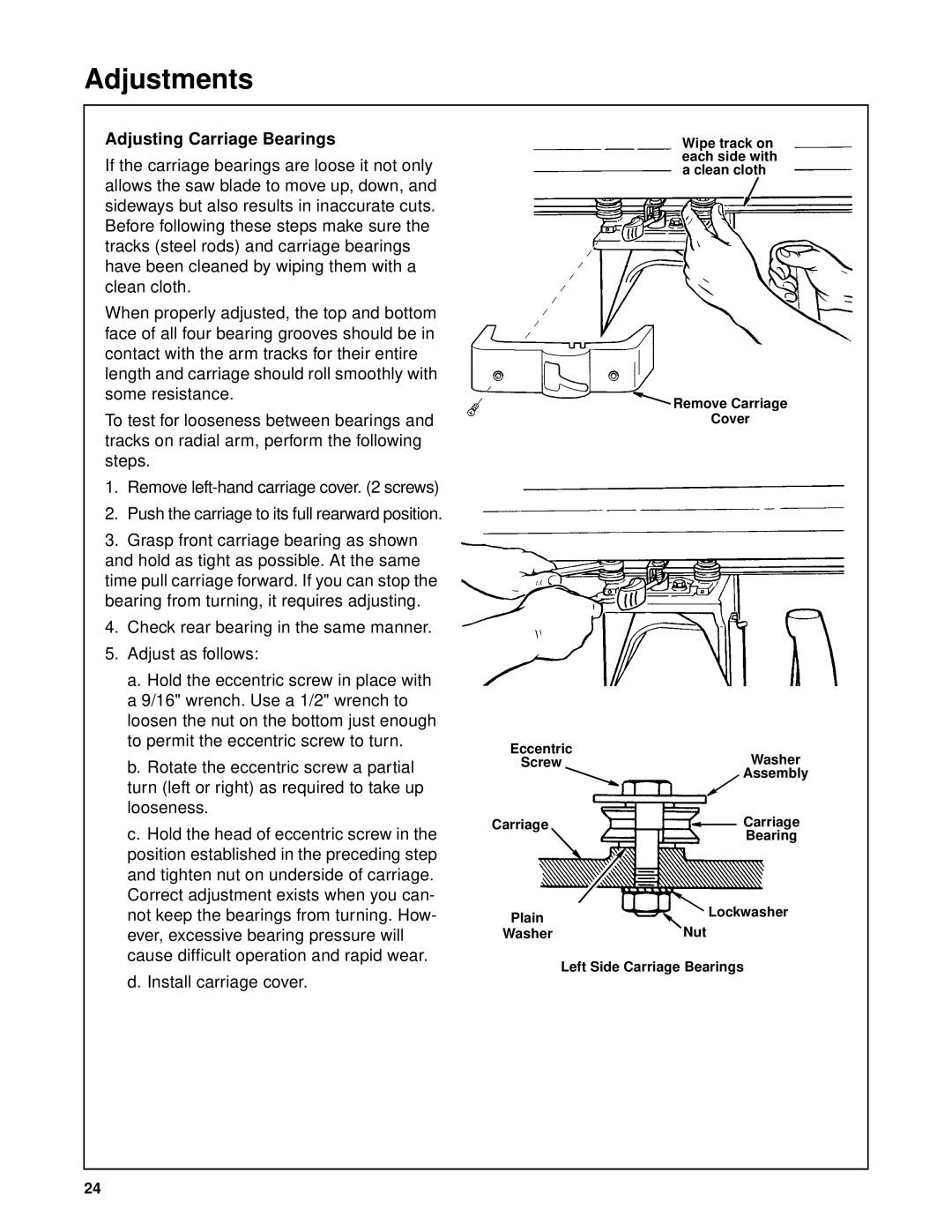

If the carriage bearings are loose it not only allows the saw blade to move up, down, and sideways but also results in inaccurate cuts. Before following these steps make sure the tracks (steel rods) and carriage bearings have been cleaned by wiping them with a clean cloth.

When properly adjusted, the top and bottom face of all four bearing grooves should be in contact with the arm tracks for their entire length and carriage should roll smoothly with some resistance.

To test for looseness between bearings and tracks on radial arm, perform the following steps.

1.Remove

2.Push the carriage to its full rearward position.

3.Grasp front carriage bearing as shown and hold as tight as possible. At the same time pull carriage forward. If you can stop the bearing from turning, it requires adjusting.

4.Check rear bearing in the same manner.

5.Adjust as follows:

a.Hold the eccentric screw in place with

a9/16" wrench. Use a 1/2" wrench to loosen the nut on the bottom just enough to permit the eccentric screw to turn.

b.Rotate the eccentric screw a partial turn (left or right) as required to take up looseness.

c.Hold the head of eccentric screw in the position established in the preceding step and tighten nut on underside of carriage. Correct adjustment exists when you can- not keep the bearings from turning. How- ever, excessive bearing pressure will cause difficult operation and rapid wear.

d.Install carriage cover.

Wipe track on each side with a clean cloth

![]() Remove Carriage

Remove Carriage

Cover

Eccentric

ScrewWasher

Assembly

Carriage |

| Carriage |

| ||

|

| Bearing |

Plain | Lockwasher |

|

WasherNut

Left Side Carriage Bearings

24