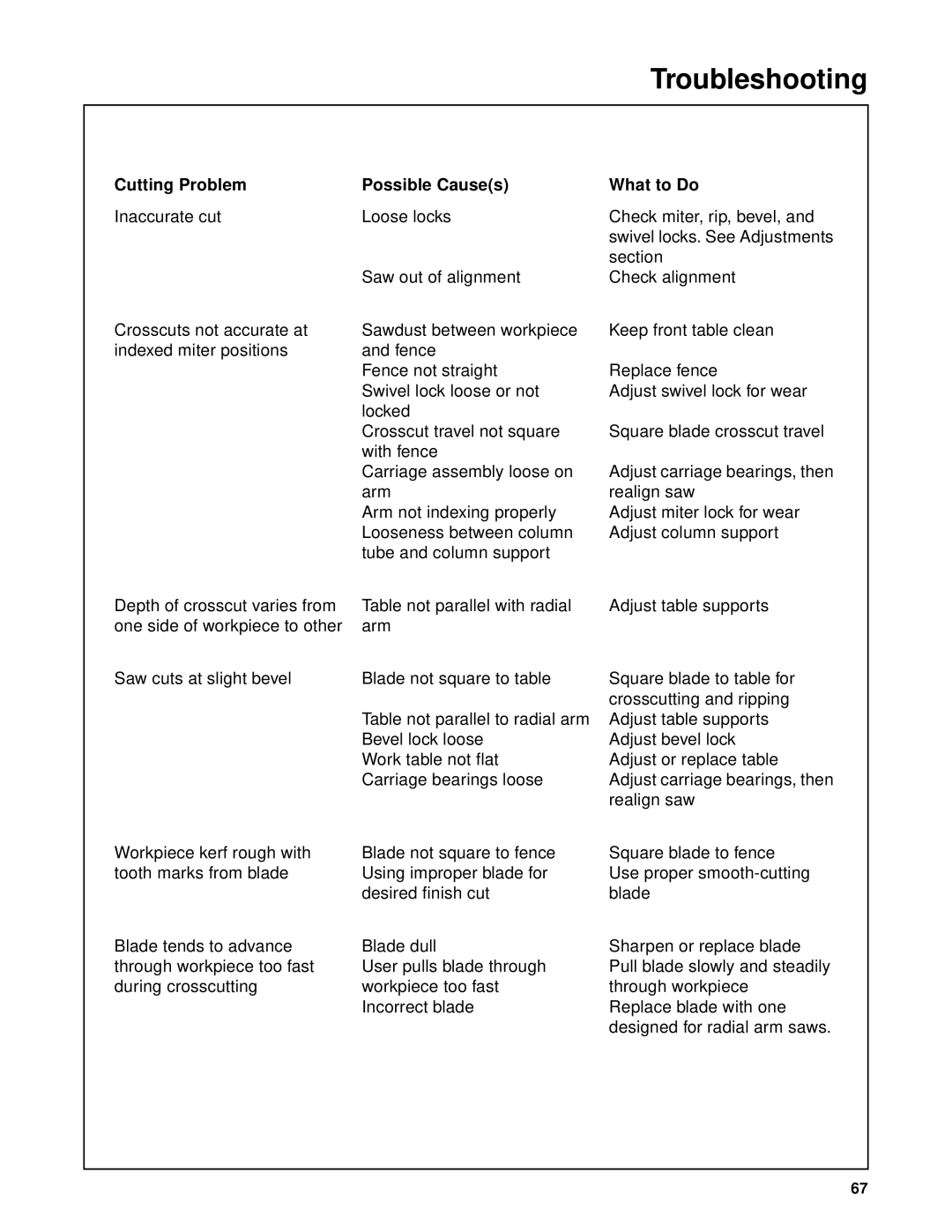

Troubleshooting

Cutting Problem | Possible Cause(s) | What to Do |

Inaccurate cut | Loose locks | Check miter, rip, bevel, and |

|

| swivel locks. See Adjustments |

|

| section |

| Saw out of alignment | Check alignment |

Crosscuts not accurate at | Sawdust between workpiece | Keep front table clean |

indexed miter positions | and fence |

|

| Fence not straight | Replace fence |

| Swivel lock loose or not | Adjust swivel lock for wear |

| locked |

|

| Crosscut travel not square | Square blade crosscut travel |

| with fence |

|

| Carriage assembly loose on | Adjust carriage bearings, then |

| arm | realign saw |

| Arm not indexing properly | Adjust miter lock for wear |

| Looseness between column | Adjust column support |

| tube and column support |

|

Depth of crosscut varies from | Table not parallel with radial | Adjust table supports |

one side of workpiece to other | arm |

|

Saw cuts at slight bevel | Blade not square to table | Square blade to table for |

|

| crosscutting and ripping |

| Table not parallel to radial arm | Adjust table supports |

| Bevel lock loose | Adjust bevel lock |

| Work table not flat | Adjust or replace table |

| Carriage bearings loose | Adjust carriage bearings, then |

|

| realign saw |

Workpiece kerf rough with tooth marks from blade

Blade tends to advance through workpiece too fast during crosscutting

Blade not square to fence Using improper blade for desired finish cut

Blade dull

User pulls blade through workpiece too fast Incorrect blade

Square blade to fence Use proper

Sharpen or replace blade Pull blade slowly and steadily through workpiece Replace blade with one designed for radial arm saws.

67