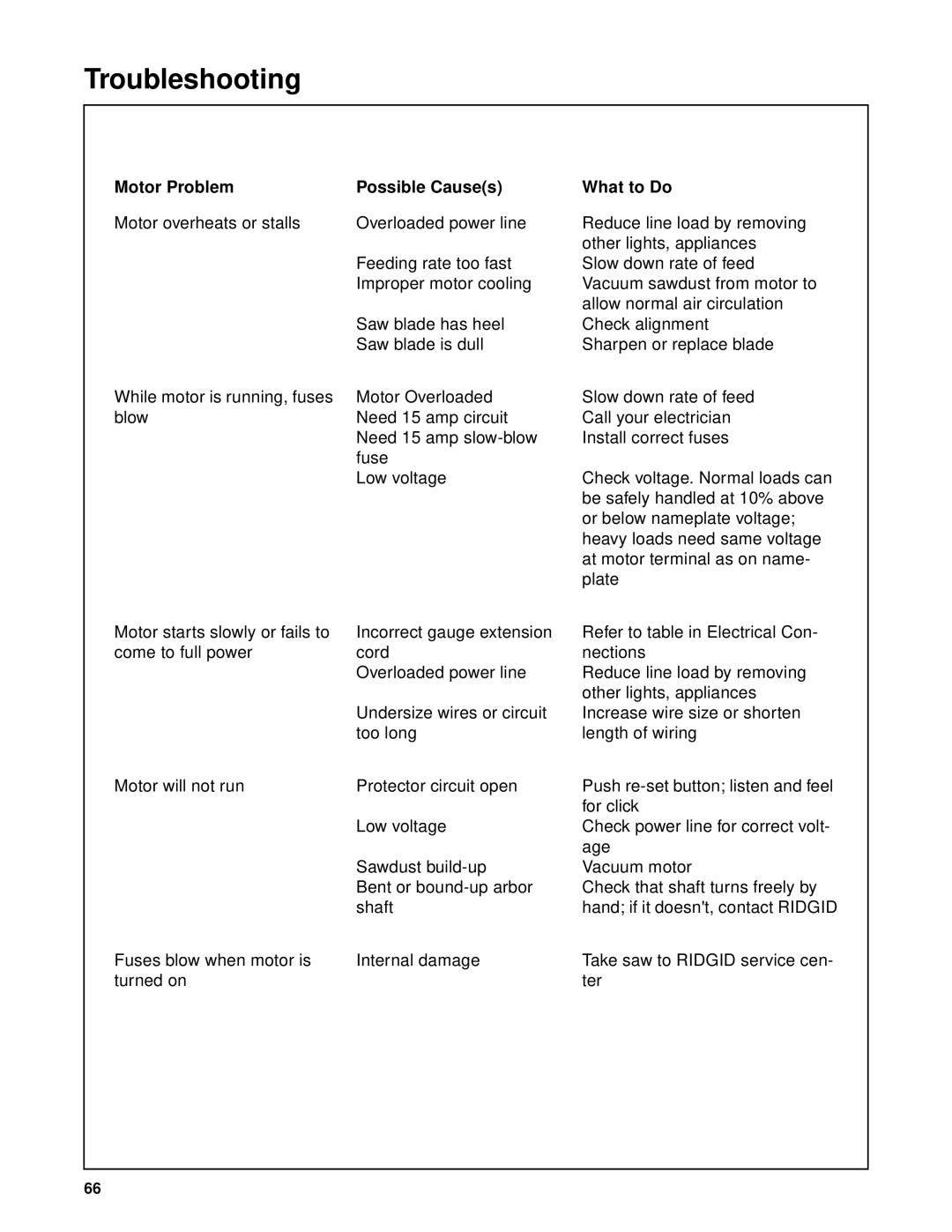

Troubleshooting

Motor Problem | Possible Cause(s) | What to Do |

Motor overheats or stalls | Overloaded power line | Reduce line load by removing |

|

| other lights, appliances |

| Feeding rate too fast | Slow down rate of feed |

| Improper motor cooling | Vacuum sawdust from motor to |

|

| allow normal air circulation |

| Saw blade has heel | Check alignment |

| Saw blade is dull | Sharpen or replace blade |

While motor is running, fuses | Motor Overloaded | Slow down rate of feed |

blow | Need 15 amp circuit | Call your electrician |

| Need 15 amp | Install correct fuses |

| fuse |

|

| Low voltage | Check voltage. Normal loads can |

|

| be safely handled at 10% above |

|

| or below nameplate voltage; |

|

| heavy loads need same voltage |

|

| at motor terminal as on name- |

|

| plate |

Motor starts slowly or fails to | Incorrect gauge extension | Refer to table in Electrical Con- |

come to full power | cord | nections |

| Overloaded power line | Reduce line load by removing |

|

| other lights, appliances |

| Undersize wires or circuit | Increase wire size or shorten |

| too long | length of wiring |

Motor will not run | Protector circuit open | Push |

|

| for click |

| Low voltage | Check power line for correct volt- |

|

| age |

| Sawdust | Vacuum motor |

| Bent or | Check that shaft turns freely by |

| shaft | hand; if it doesn't, contact RIDGID |

Fuses blow when motor is | Internal damage | Take saw to RIDGID service cen- |

turned on |

| ter |

66