Safety

6.Set of pawls to be lowered to the work- piece surface for ripping. They allow the workpiece to pass freely from infeed to out- feed side, but help stop the kickback motion from outfeed to infeed side by grabbing into the workpiece surface. Pawls must be reset each time a different thickness workpiece is cut.

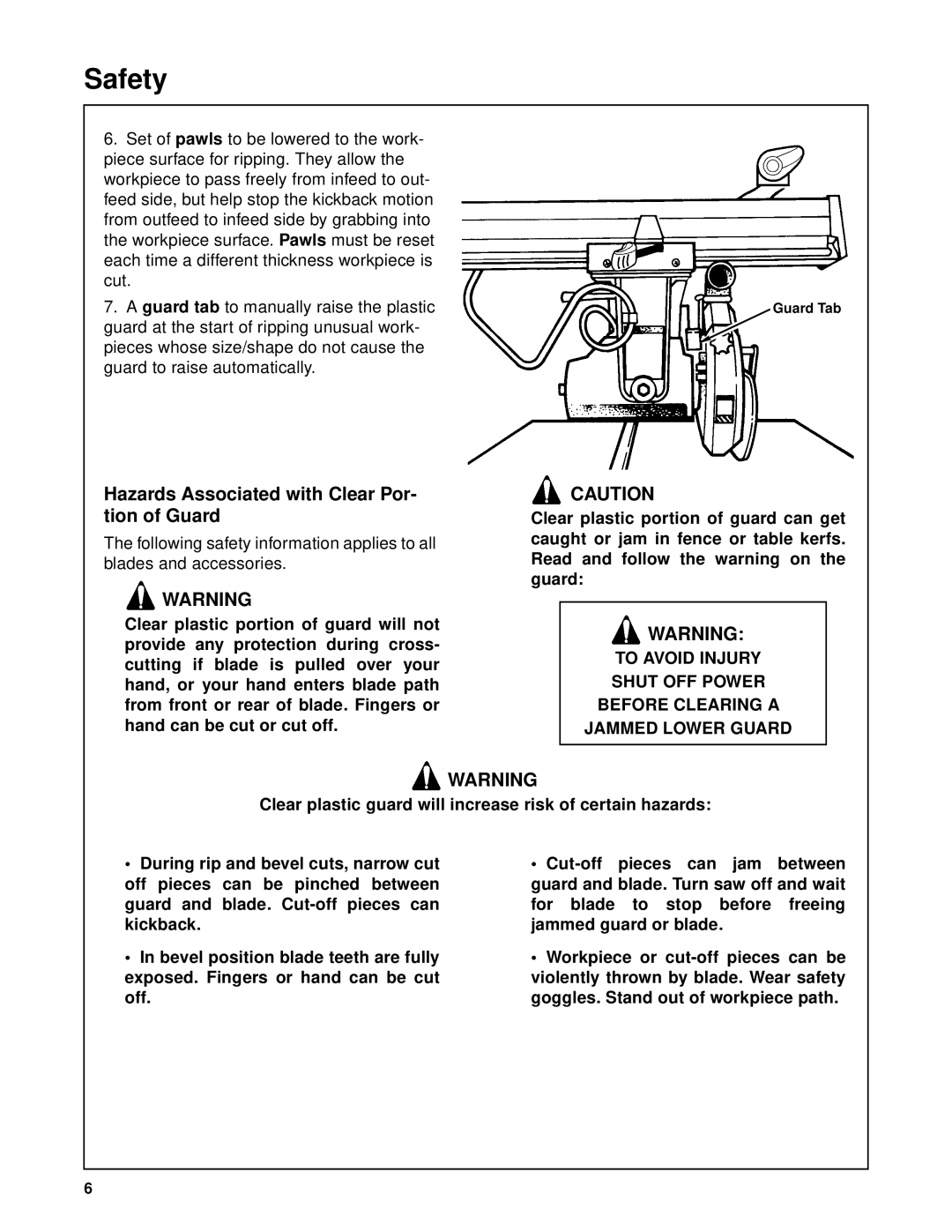

7. A guard tab to manually raise the plastic | Guard Tab |

guard at the start of ripping unusual work- |

|

pieces whose size/shape do not cause the |

|

guard to raise automatically. |

|

Hazards Associated with Clear Por- tion of Guard

The following safety information applies to all blades and accessories.

![]() WARNING

WARNING

Clear plastic portion of guard will not provide any protection during cross- cutting if blade is pulled over your hand, or your hand enters blade path from front or rear of blade. Fingers or hand can be cut or cut off.

CAUTION

Clear plastic portion of guard can get caught or jam in fence or table kerfs. Read and follow the warning on the guard:

![]() WARNING:

WARNING:

TO AVOID INJURY

SHUT OFF POWER

BEFORE CLEARING A

JAMMED LOWER GUARD

![]() WARNING

WARNING

Clear plastic guard will increase risk of certain hazards:

•During rip and bevel cuts, narrow cut off pieces can be pinched between guard and blade.

•In bevel position blade teeth are fully exposed. Fingers or hand can be cut off.

•

•Workpiece or

6