Ripping

7.Remove workpiece from table.

8.Ready push stick or push block.

9.Set up table extension(s) and support their outer ends. Do not use another per- son to support workpieces because this can cause kickback and it exposes helper to potential hazards at outfeed side.

Special Notes for Bevel

![]() CAUTION

CAUTION

Bevel ripping creates unique problems of visibility and feeding. Before cut- ting, check the

![]() WARNING

WARNING

Bevel the edge that is not against the fence.

1.When setting bevel angle, raise radial arm to allow sufficient clearance for blade and guard to not jam in table.

2.When blade is beveled manually raise clear plastic guard before lowering blade to table or kerf, otherwise it may jam in the table.

3.To set hold down, place workpiece directly under guard nose, rather than paral- lel to blade.

4.To set pawls, place workpiece directly under set of pawls closer to table. This set of pawls will keep contact with workpiece sur- face.

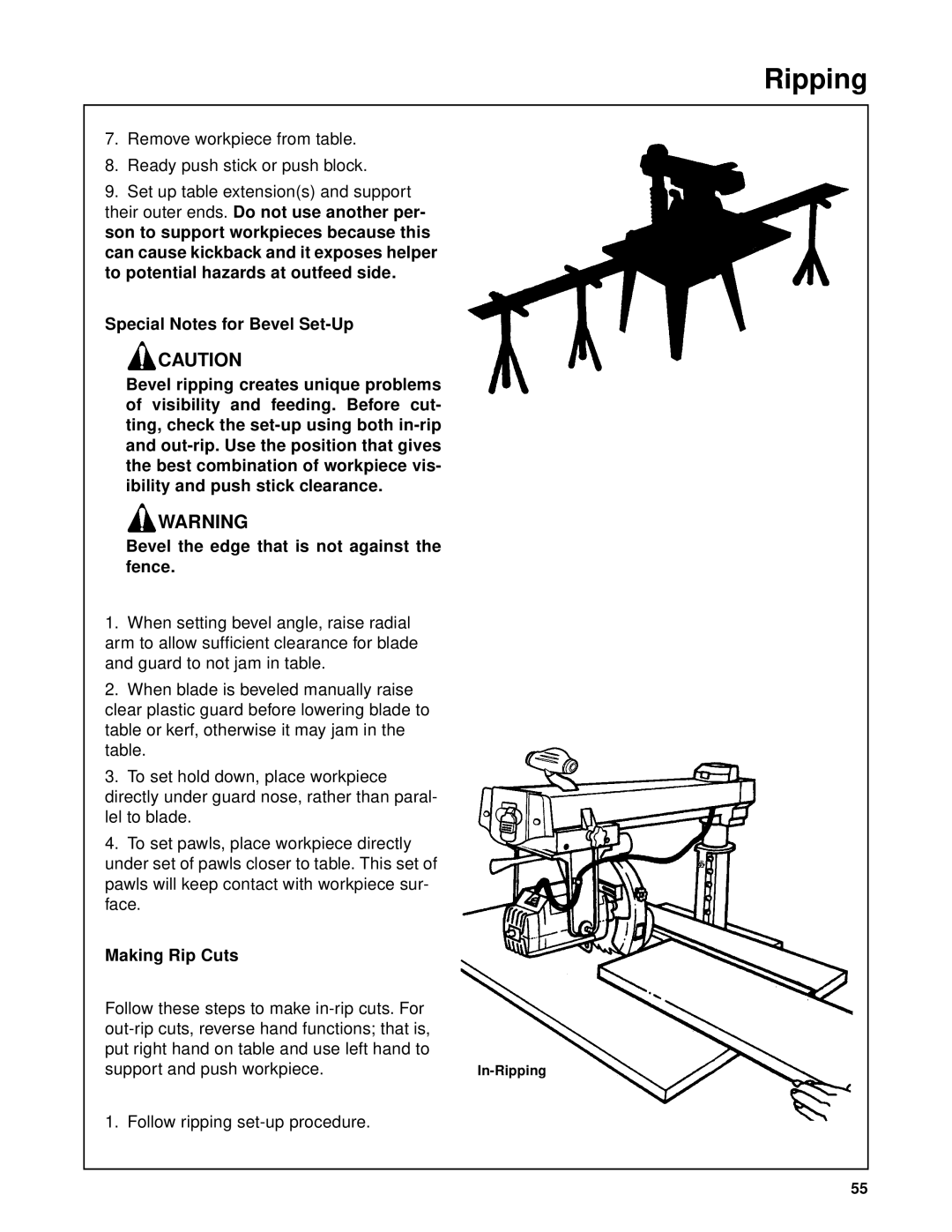

Making Rip Cuts |

|

Follow these steps to make |

|

| |

put right hand on table and use left hand to |

|

support and push workpiece. | |

1. Follow ripping |

|

55