SECTION 14: OPERATION

14.1.1 Heater Lockout Indicator by Connector

A 230 V signal is provided which enables the ROBERTS GORDON® controller, BMS system, etc. to indicate the heater that has failed. An additional wire has to be installed from the heater lockout indicator connector to the monitoring computer. See Page 57, Section 13.5.

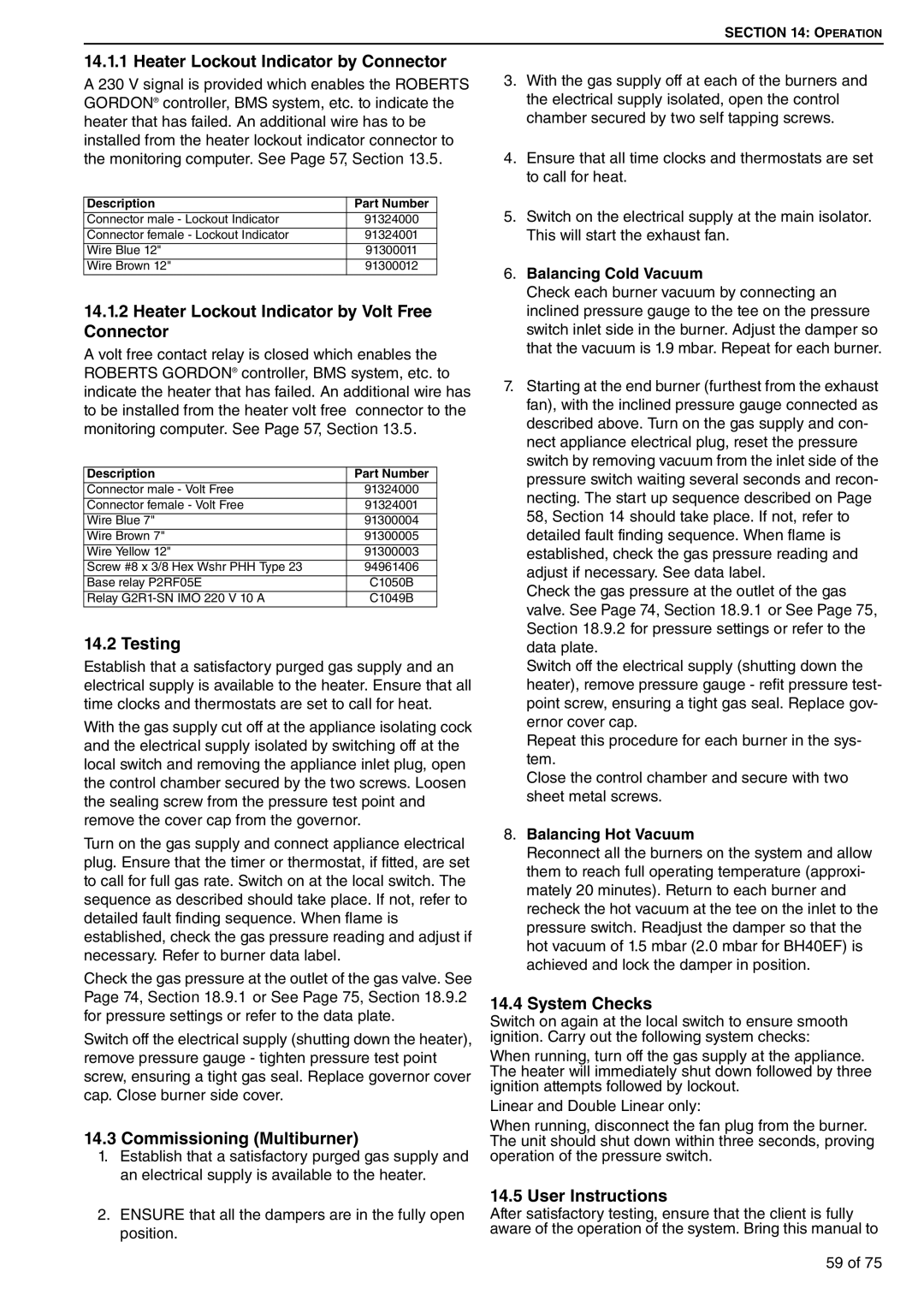

Description | Part Number |

Connector male - Lockout Indicator | 91324000 |

Connector female - Lockout Indicator | 91324001 |

Wire Blue 12" | 91300011 |

Wire Brown 12" | 91300012 |

14.1.2Heater Lockout Indicator by Volt Free Connector

Avolt free contact relay is closed which enables the ROBERTS GORDON® controller, BMS system, etc. to indicate the heater that has failed. An additional wire has to be installed from the heater volt free connector to the monitoring computer. See Page 57, Section 13.5.

Description | Part Number |

Connector male - Volt Free | 91324000 |

Connector female - Volt Free | 91324001 |

Wire Blue 7" | 91300004 |

Wire Brown 7" | 91300005 |

Wire Yellow 12" | 91300003 |

Screw #8 x 3/8 Hex Wshr PHH Type 23 | 94961406 |

Base relay P2RF05E | C1050B |

Relay | C1049B |

14.2 Testing

Establish that a satisfactory purged gas supply and an electrical supply is available to the heater. Ensure that all time clocks and thermostats are set to call for heat.

With the gas supply cut off at the appliance isolating cock and the electrical supply isolated by switching off at the local switch and removing the appliance inlet plug, open the control chamber secured by the two screws. Loosen the sealing screw from the pressure test point and remove the cover cap from the governor.

Turn on the gas supply and connect appliance electrical plug. Ensure that the timer or thermostat, if fitted, are set to call for full gas rate. Switch on at the local switch. The sequence as described should take place. If not, refer to detailed fault finding sequence. When flame is established, check the gas pressure reading and adjust if necessary. Refer to burner data label.

Check the gas pressure at the outlet of the gas valve. See Page 74, Section 18.9.1 or See Page 75, Section 18.9.2 for pressure settings or refer to the data plate.

Switch off the electrical supply (shutting down the heater), remove pressure gauge - tighten pressure test point screw, ensuring a tight gas seal. Replace governor cover cap. Close burner side cover.

14.3 Commissioning (Multiburner)

1.Establish that a satisfactory purged gas supply and an electrical supply is available to the heater.

2.ENSURE that all the dampers are in the fully open position.

3.With the gas supply off at each of the burners and the electrical supply isolated, open the control chamber secured by two self tapping screws.

4.Ensure that all time clocks and thermostats are set to call for heat.

5.Switch on the electrical supply at the main isolator. This will start the exhaust fan.

6.Balancing Cold Vacuum

Check each burner vacuum by connecting an inclined pressure gauge to the tee on the pressure switch inlet side in the burner. Adjust the damper so that the vacuum is 1.9 mbar. Repeat for each burner.

7.Starting at the end burner (furthest from the exhaust fan), with the inclined pressure gauge connected as described above. Turn on the gas supply and con- nect appliance electrical plug, reset the pressure switch by removing vacuum from the inlet side of the pressure switch waiting several seconds and recon- necting. The start up sequence described on Page 58, Section 14 should take place. If not, refer to detailed fault finding sequence. When flame is established, check the gas pressure reading and adjust if necessary. See data label.

Check the gas pressure at the outlet of the gas

valve. See Page 74, Section 18.9.1 or See Page 75, Section 18.9.2 for pressure settings or refer to the data plate.

Switch off the electrical supply (shutting down the heater), remove pressure gauge - refit pressure test- point screw, ensuring a tight gas seal. Replace gov- ernor cover cap.

Repeat this procedure for each burner in the sys- tem.

Close the control chamber and secure with two sheet metal screws.

8.Balancing Hot Vacuum

Reconnect all the burners on the system and allow them to reach full operating temperature (approxi- mately 20 minutes). Return to each burner and recheck the hot vacuum at the tee on the inlet to the pressure switch. Readjust the damper so that the hot vacuum of 1.5 mbar (2.0 mbar for BH40EF) is achieved and lock the damper in position.

14.4 System Checks

Switch on again at the local switch to ensure smooth ignition. Carry out the following system checks:

When running, turn off the gas supply at the appliance. The heater will immediately shut down followed by three ignition attempts followed by lockout.

Linear and Double Linear only:

When running, disconnect the fan plug from the burner. The unit should shut down within three seconds, proving operation of the pressure switch.

14.5 User Instructions

After satisfactory testing, ensure that the client is fully

aware of the operation of the system. Bring this manual to

59 of 75