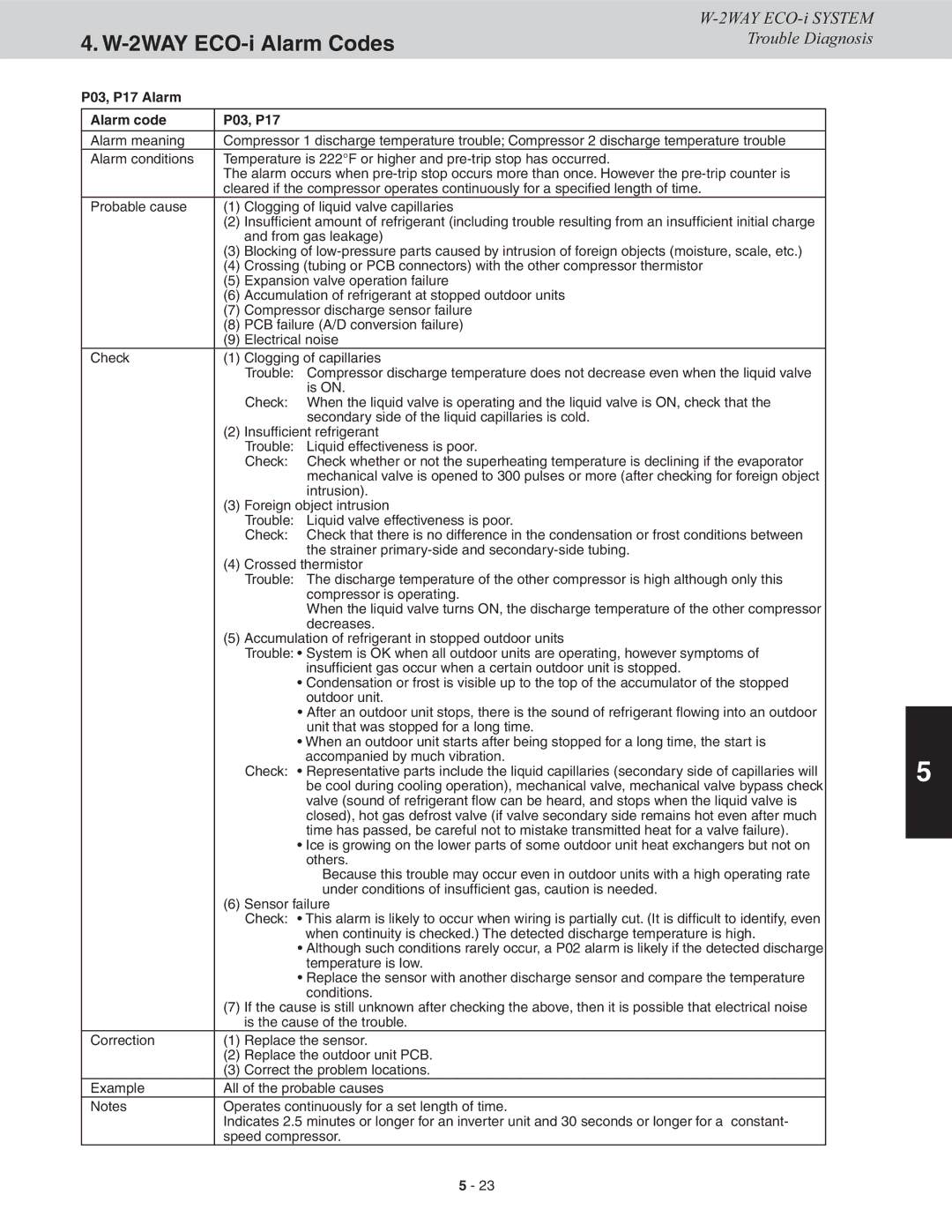

4. W-2WAY ECO-i Alarm Codes

P03, P17 Alarm |

|

|

|

|

|

Alarm code | P03, P17 |

|

|

| |

|

|

|

| ||

Alarm meaning | Compressor 1 discharge temperature trouble; Compressor 2 discharge temperature trouble |

|

| ||

Alarm conditions | Temperature is 222°F or higher and |

|

| ||

| The alarm occurs when |

|

| ||

| cleared if the compressor operates continuously for a specified length of time. |

|

| ||

Probable cause | (1) Clogging of liquid valve capillaries |

|

| ||

| (2) | Insufficient amount of refrigerant (including trouble resulting from an insufficient initial charge |

|

| |

|

| and from gas leakage) |

|

| |

| (3) | Blocking of |

|

| |

| (4) | Crossing (tubing or PCB connectors) with the other compressor thermistor |

|

| |

| (5) | Expansion valve operation failure |

|

| |

| (6) | Accumulation of refrigerant at stopped outdoor units |

|

| |

| (7) | Compressor discharge sensor failure |

|

| |

| (8) | PCB failure (A/D conversion failure) |

|

| |

| (9) | Electrical noise |

|

| |

Check | (1) Clogging of capillaries |

|

| ||

|

| Trouble: Compressor discharge temperature does not decrease even when the liquid valve |

|

| |

|

|

| is ON. |

|

|

|

| Check: | When the liquid valve is operating and the liquid valve is ON, check that the |

|

|

|

|

| secondary side of the liquid capillaries is cold. |

|

|

| (2) | Insufficient refrigerant |

|

| |

|

| Trouble: | Liquid effectiveness is poor. |

|

|

|

| Check: | Check whether or not the superheating temperature is declining if the evaporator |

|

|

|

|

| mechanical valve is opened to 300 pulses or more (after checking for foreign object |

|

|

|

|

| intrusion). |

|

|

| (3) | Foreign object intrusion |

|

| |

|

| Trouble: | Liquid valve effectiveness is poor. |

|

|

|

| Check: | Check that there is no difference in the condensation or frost conditions between |

|

|

|

|

| the strainer |

|

|

| (4) | Crossed thermistor |

|

| |

|

| Trouble: The discharge temperature of the other compressor is high although only this |

|

| |

|

|

| compressor is operating. |

|

|

|

|

| When the liquid valve turns ON, the discharge temperature of the other compressor |

|

|

|

|

| decreases. |

|

|

| (5) | Accumulation of refrigerant in stopped outdoor units |

|

| |

|

| Trouble: • System is OK when all outdoor units are operating, however symptoms of |

|

| |

|

|

| insufficient gas occur when a certain outdoor unit is stopped. |

|

|

|

|

| • Condensation or frost is visible up to the top of the accumulator of the stopped |

|

|

|

|

| outdoor unit. |

|

|

|

|

| • After an outdoor unit stops, there is the sound of refrigerant flowing into an outdoor |

|

|

|

|

| unit that was stopped for a long time. |

|

|

|

|

| • When an outdoor unit starts after being stopped for a long time, the start is |

|

|

|

|

| accompanied by much vibration. |

| 5 |

|

| Check: • Representative parts include the liquid capillaries (secondary side of capillaries will |

| ||

|

|

| be cool during cooling operation), mechanical valve, mechanical valve bypass check |

|

|

|

|

| valve (sound of refrigerant flow can be heard, and stops when the liquid valve is |

|

|

|

|

| closed), hot gas defrost valve (if valve secondary side remains hot even after much |

|

|

|

|

| time has passed, be careful not to mistake transmitted heat for a valve failure). |

|

|

|

|

| • Ice is growing on the lower parts of some outdoor unit heat exchangers but not on |

|

|

|

|

| others. |

|

|

|

|

| Because this trouble may occur even in outdoor units with a high operating rate |

|

|

|

|

| under conditions of insufficient gas, caution is needed. |

|

|

| (6) | Sensor failure |

|

| |

|

| Check: • This alarm is likely to occur when wiring is partially cut. (It is difficult to identify, even |

|

| |

|

|

| when continuity is checked.) The detected discharge temperature is high. |

|

|

|

|

| • Although such conditions rarely occur, a P02 alarm is likely if the detected discharge |

|

|

|

|

| temperature is low. |

|

|

|

|

| • Replace the sensor with another discharge sensor and compare the temperature |

|

|

|

|

| conditions. |

|

|

| (7) | If the cause is still unknown after checking the above, then it is possible that electrical noise |

|

| |

|

| is the cause of the trouble. |

|

| |

Correction | (1) Replace the sensor. |

|

| ||

| (2) | Replace the outdoor unit PCB. |

|

| |

| (3) | Correct the problem locations. |

|

| |

Example | All of the probable causes |

|

| ||

Notes | Operates continuously for a set length of time. |

|

| ||

| Indicates 2.5 minutes or longer for an inverter unit and 30 seconds or longer for a constant- |

|

| ||

| speed compressor. |

|

| ||

5 - 23