basic saw operations

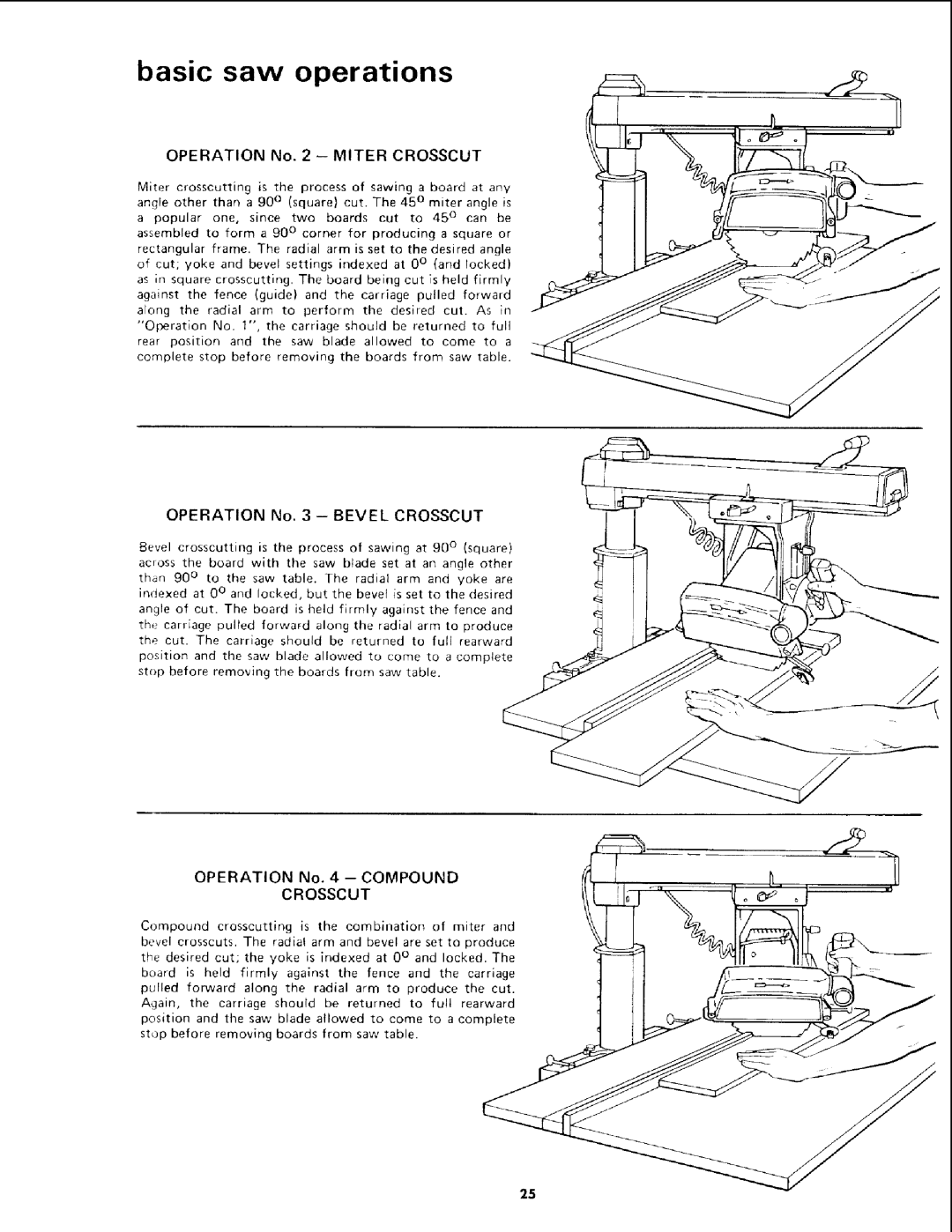

OPERATION No. 2 - MITER CROSSCUT

Miter crosscutting is the process of sawing a board at any angle other than a 90 ° (square} cut. The 45 ° miter angle is

a popular one, since two boards cut to 45 ° can be

assembled to form a 90 ° corner for producing a square or

rectangular | frame. | The | radial | arm | is set | to | the | desired | angle | |

of | cut; yoke | and | bevel | settings | indexed | at | 0 ° | (and | locked) | |

as | if] square | crosscutting. | The | board | being | cut | Ts held | firmly | ||

against the fence (guide} and the carriage pulled forward along the radial arm to perform the desired cut. As in

"Operation No. 1", the carriage should be returned to full

rear position and the saw blade allowed to come to a complete stop before removing the boards from saw table.

OPERATION No. 3 - BEVEL CROSSCUT

Bevel crosscutting is the process of sawing at 90 ° (square} across the board with the saw blade set at an angle other than 90 ° to the saw table. The radial arm and yoke are indexed at 0 ° and locked, but the bevel is set to the desired

angle of cut. The board is held firmly against the fence and the carriage pulled forward along the radial arm to produce

the cut. The carriage should be returned to full rearward position and the saw blade allowed to come to a complete stop before removing the boards from saw table.

OPERATION No. 4 -- COMPOUND

CROSSCUT

Compound crosscutting is the combination of miter and bevel crosscuts. The radia! arm and bevel are set to produce the desired cut; the yoke is indexed at 0 ° and locked. The

board is held firmly against the fence and the carriage

pulled forward along the radial arm to produce the cut.

Again, the carriage should be returned to full rearward position and the saw blade allowed to come to a complete stop before removing boards from saw table.

25