additional safety instructions

removed from the saw arbor before using the accessory shaft (rear end of the saw motor). NEVER

operate the saw with cutting tools iincluding sanding accessories) installed on both ends of the saw arbor.

(B} RIPPING

Ripping is cutting with the grain or the tong way of the

board - it is performed by pushing the workpiece

along the fence and thru the sawblade (sawblade parallel to the fence).

1.Never apply the feed force to the section of the workpiece that will become the

Feed force when ripping must always be applied between the saw blade and the fence . . . use a

"PUSH STICK" (see pg. 26) for narrow or short work.

2.Whenever possible, use the

provides minimum obstruction for feeding by hand or push stick as appropriate.

3.Do not release the workpiece before operation is complete - push the workpiece atl the way past the rear (outfeed or exit) of the sawblade.

4.Make sure by trial before starting the cut that the

antikickback pawls will stop a kickback once it has started. Keep points of pawls SHARP!

5.Use a push stick when ripping short (under 12 inches) or narrow (under 6 inches wide) workpieces.

6. | CAUTION: |

|

| Never |

| reposition | the | Guard | or | |||||||||||

| antikickback |

| with | power | "ON". |

|

|

|

|

|

|

| ||||||||

7. | A | "KICKBACK" |

|

| occurs | during | a | operation | ||||||||||||

| when | a | part | or | all | of | the | workpiece |

| is thrown |

| back | ||||||||

| violently | toward |

| the | operator. | It | can | occur | when | |||||||||||

| the | workpiece |

| closes | in | on | the | rear | (outfeed |

| side) of | |||||||||

| the |

| sawblade |

| (pinching), |

|

| binds | between |

| the fence | |||||||||

| and | the sawblade |

| (heel), |

| or | is | grabbed |

| by | the | |||||||||

| sawblade | teeth |

| feed) | at | the | outfeed | |||||||||||||

| side. |

| "PINCHING" |

|

|

| is |

| generally |

| avoided | by | ||||||||

| utilization | of |

| the | spreader, | and | a sharp | sawblade | of | |||||||||||

| the |

| correct |

| type | for | the | workpiece |

| being | cut. | |||||||||

| "HEEL" | can | be | avoided | by | maintaining |

| the | ||||||||||||

| sawblade exactly parallel to the fence. Grabbing by | |||||||||||||||||||

| the sawblade teeth can be caused by heel or by | |||||||||||||||||||

| feeding | from | the | wrong |

| direction | (see "DANGER" | |||||||||||||

| warning | on |

| guard) |

| - |

| it | can | be | avoided | by | ||||||||

| maintaining |

| parallelism |

|

| of |

| sawblade | to | fence, | ||||||||||

| feeding | into | the sawblade from the nose of the | |||||||||||||||||

| guard |

| only, |

|

| by | positioning |

| the | spreader | and | |||||||||

| antikickback |

| properly, |

| and |

| keeping | the | workpiece | |||||||||||

| clown on the table and against the fence. |

|

|

|

| |||||||||||||||

8.Position the nose of the guard to just clear the

workpiece, and position/adjust the antikickback and spreader devices as instructed.

9.NEVER cut more than one piece at a time by stacking workpieces vertically.

10.NEVER feed a workpiece thru the saw with another

piece (butting second piece against trailing edge of piece being cut), even if of the same thickness. Feed

each workpiece individually thru the sawblade, and

completely beyond the sawblade, before ripping the

next workpiece. Use push stick if the rip cut is less than 6'" wide.

11, DO NOT pul! the workpiece thru the sawblade

-position your body at the nose

side. This will require added table support for long pieces.

12. Plastic and composition (like hardboard) materials may be cut on your saw. However, since these are usually quite hard and slippery, the antikickback pawls may not stop a kickback.

for radial saws

Therefore, rip with the finished side down (next to the table) and be especially attentive to following proper

13.When sawing 1/4" or thinner materials, follow at! normal ripping procedures except set sawblade into

table top at least 1/8". DO NOT let go of or stop feeding the workpiece between the blade and fence

until you have pushed it completely past the

antikickbaek pawls. Otherwise the workpiece could get into the back of the sawblade and be thrown

violently from the saw in the direction opposite to

the feed direction. This is the same action that

would occur if the instructions of the DANGER warning on the guard is aborted. Do not stand, or permit anyone else to stand, in line with the path of

a workpiece that may be thrown from the saw in this manner.

14.Position the saw so neither you, a helper, or a casuat

observer is forced to stand in line with the sawblade.

15.Use extra care when ripping wood that has a twisted

grain or is twisted or bowed it may rock on the table and/or pinch the sawblade.

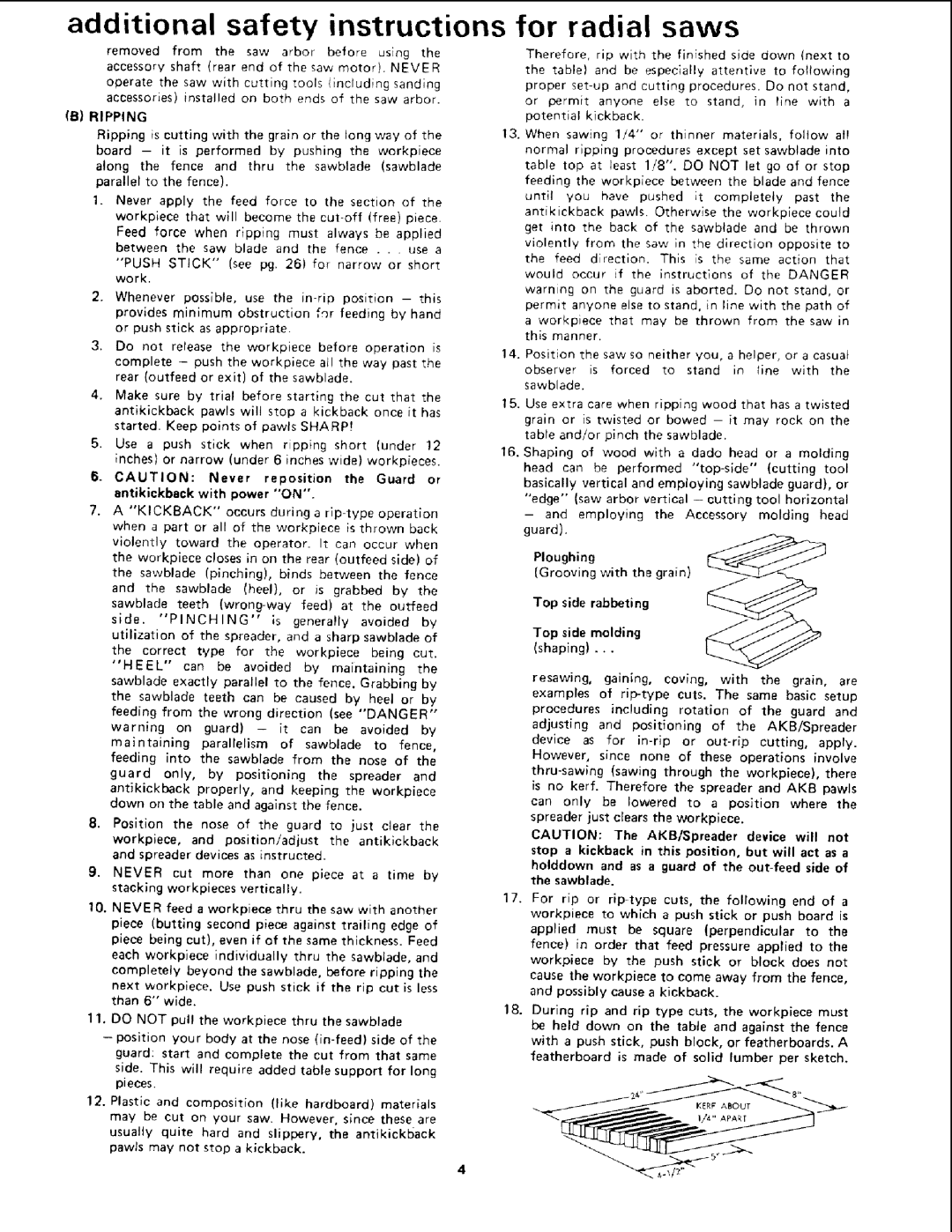

16.Shaping of wood with a dado head or a molding

head can be performed

basically vertical and employing sawblade guard}, or "edge" (saw arbor vertical

- and employing the Accessory molding head guard).

Ploughing

(Grooving with the grain)

Top side rabbeting

Top side molding

(shaping)...

resawing, gaining, coving, with the grain, are

examples of

procedures including rotation of the guard and

adjusting and positioning of the AKB/Spreader

device as for

However, since none of these operations involve

can only be lowered to a position where the spreader just clears the workpiece.

CAUTION: The AKB/Spreader device will not stop a kickback in this position, but will act as a

holddown and as a guard of the

17.For rip or

applied must be square (perpendicular to the fence) in order that feed pressure applied to the

workpiece by the push stick or block does not cause the workpiece to come away from the fence, and possibly cause a kickback.

18.During rip and rip type cuts, the workpiece must be held down on the table and against the fence

with a push stick, push block, or featherboards. A

featherboard is made of solid lumber per sketch.