trouble-shooting

5. WOOD BINDS, SMOKES AND MOTOR SLOWS DOWN OR STOPS WHEN RIPPING.

a.Dull blade or warped board.

Sharpen or replace the saw blade. Avoid the attempted use of severly warped material.

b.Feed rate too fast. Slow Feed Rate.

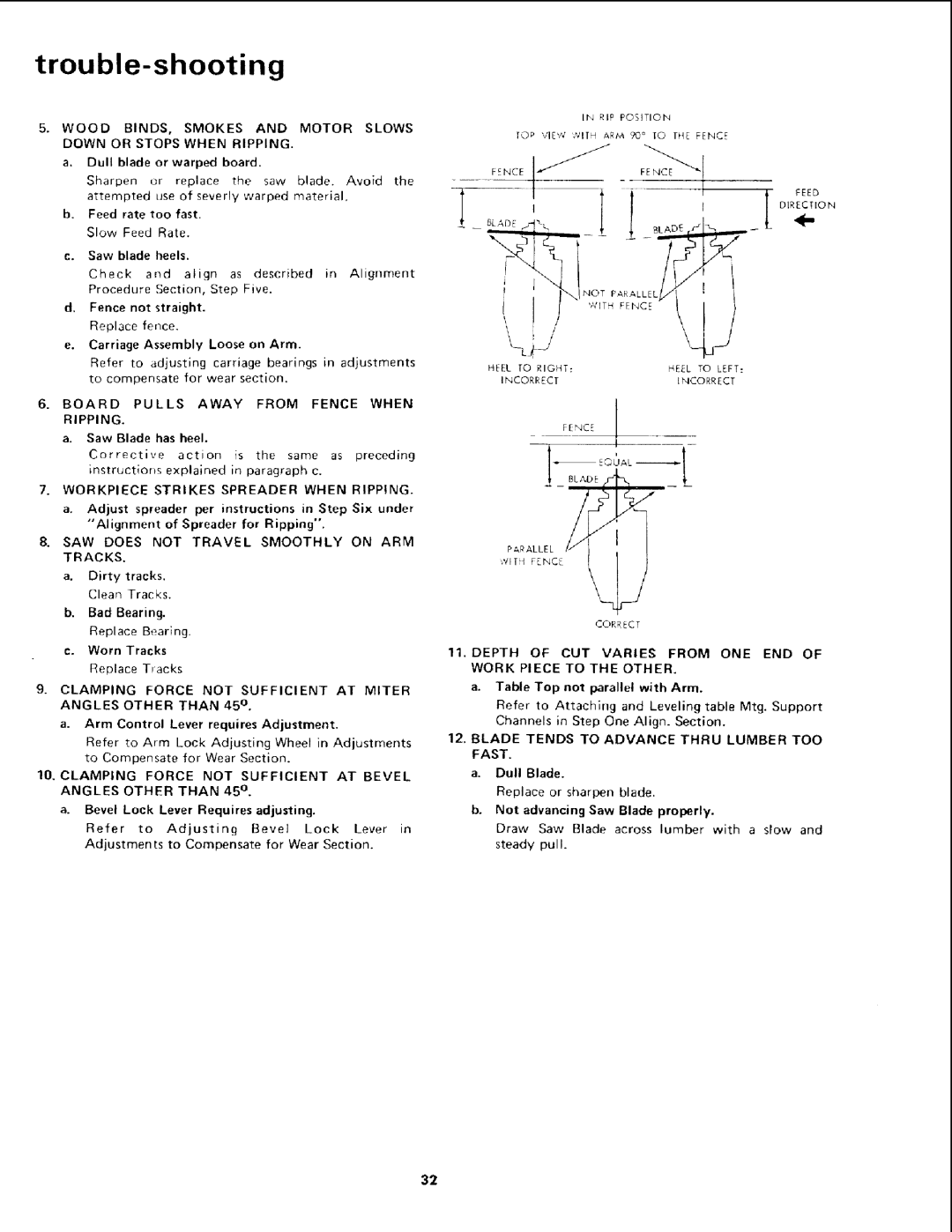

c.Saw blade heels.

Check and align as described in Alignment Procedure Section, Step Five.

d.Fence not straight. Replace fence.

e.Carriage Assembly Loose on Arm.

Refer to adjusting carriage bearings in adjustments to compensate for wear section,

6.BOARD PULLS AWAY FROM FENCE WHEN

RIPPING.

a.Saw Blade has heel.

Corrective action is the same as preceding

instructions explained in paragraph c.

7. WORKPIECE STRIKES SPREADER WHEN RIPPING.

a. Adjust spreader per instructions in Step Six under "'Alignment of Spreader for Ripping".

& SAW DOES NOT TRAVEL SMOOTHLY ON ARM TRACKS.

a.Dirty tracks. Clean Tracks.

b.Bad Bearing. Replace Bearing.

c.Worn Tracks Replace Tracks

9.CLAMPING FORCE NOT SUFFICIENT AT MITER ANGLES OTHER THAN 45 ° .

a.Arm Control Lever requires Adjustment.

Refer to Arm Lock Adjusting Wheel in Adjustments to Compensate for Wear Section.

10.CLAMPING FORCE NOT SUFFICIENT AT BEVEL ANGLES OTHER THAN 45 ° .

a.Bevel Lock Lever Requires adjusting.

Refer to Adjusting Bevel Lock Lever in

Adjustments to Compensate for Wear Section.

IN RIP POSITION

TOp vIEW WITH ARM 90 ° TO THE FENCE

DIRECTION

FEED

I ] ) Vq T_FkFALc EE

\Y

HEEL TO | RIGHT: | HEEL TO LEFT: |

I NCORR | ECT | i NCORRECT |

| FENCE |

|

WlTi FENCE

CORRECT

11. DEPTH OF CUT VARIES FROM ONE END OF WORK PIECE TO THE OTHER.

a.Table Top not parallel with Arm.

Refer to Attaching and Leveling table Mtg. Support Channels in Step One Align. Section.

12.BLADE TENDS TO ADVANCE THRU LUMBER TOO FAST.

a.Dull Blade.

Replace or sharpen blade.

b.Not advancing Saw Blade properly.

Draw Saw Blade across lumber with a slow and steady pull.

32