BEVELCROSSCUTTING

BEVEL CROSSCUTTING is the same as crosscutting except that the wood is also cut at an angle . •. other than g0 degrees with the flat side of the wood.

Adjust the blade to the desired angle.

Use the miter gage in the groove to the RIGHT of the blade

•..NEVER TO THE LEFT. Hold the workpiece with your right hand and the Iockhandle with your left hand ... or use

48).

COMPOUND MITER CUTTING

Compound miter cutting is a combination of miter cutting and bevel crosscutting. The cut is made at an angle other than 90 degrees to both the edg_ and the flat side of the wood.

Adjust the miter gage and the blade to the desired angle

•..make sure miter gage is locked.

Use the miter gagein the groove to the RIGHT of the blade

•..NEVER TO THE LEFT. Hold the workpiece with your right hand and the Iockhandle with your left hand ... or use

RIPPING, BEVEL RIPPING, RESAWING AND

RABBETING (along the edge of a workpiece) are

performed using the RIP FENCE together with AUXILIARY deviceswhen required.

WARNING: FOR YOUR OWN SAFETY, ALWAYS OBSERVE THE FOLLOWING SAFETY PRECAUTIONS.

1.Never make these cuts FREEHAND (without using the

rip fence or auxiliary devices when required) because

the blade could bind in the cut and cause a

KICKBACK.

2.Always lock the rip fence securely when in use.

3.Remove miter gage from table.

4.Make sure blade guard is installed for all rip type cuts.

Replace the guard IMMEDIATELY following completion of resawing, rabbeting, dadoing, or molding operations.

Frequently check the action of the

Pull the workpiece TOWARD you. If the PAWLS do not DIG into the workpiece and HOLD it ... the pawls must be SHARPENED. Refer to "Maintenance" section further on in this manual.

5.Have blade extend approximately 1/8 inch above top of

workpiece. Additional blade exposure could be hazardous.

6.Do not stand directly in front of the blade in case of a

KICKBACK. Stand to either side of the blade.

7.Keep your hands clear of the blade and out of the path of the blade.

B. If the blade stalls or stops while cutting, TURN

SWITCH OFF before attempting to free the blade.

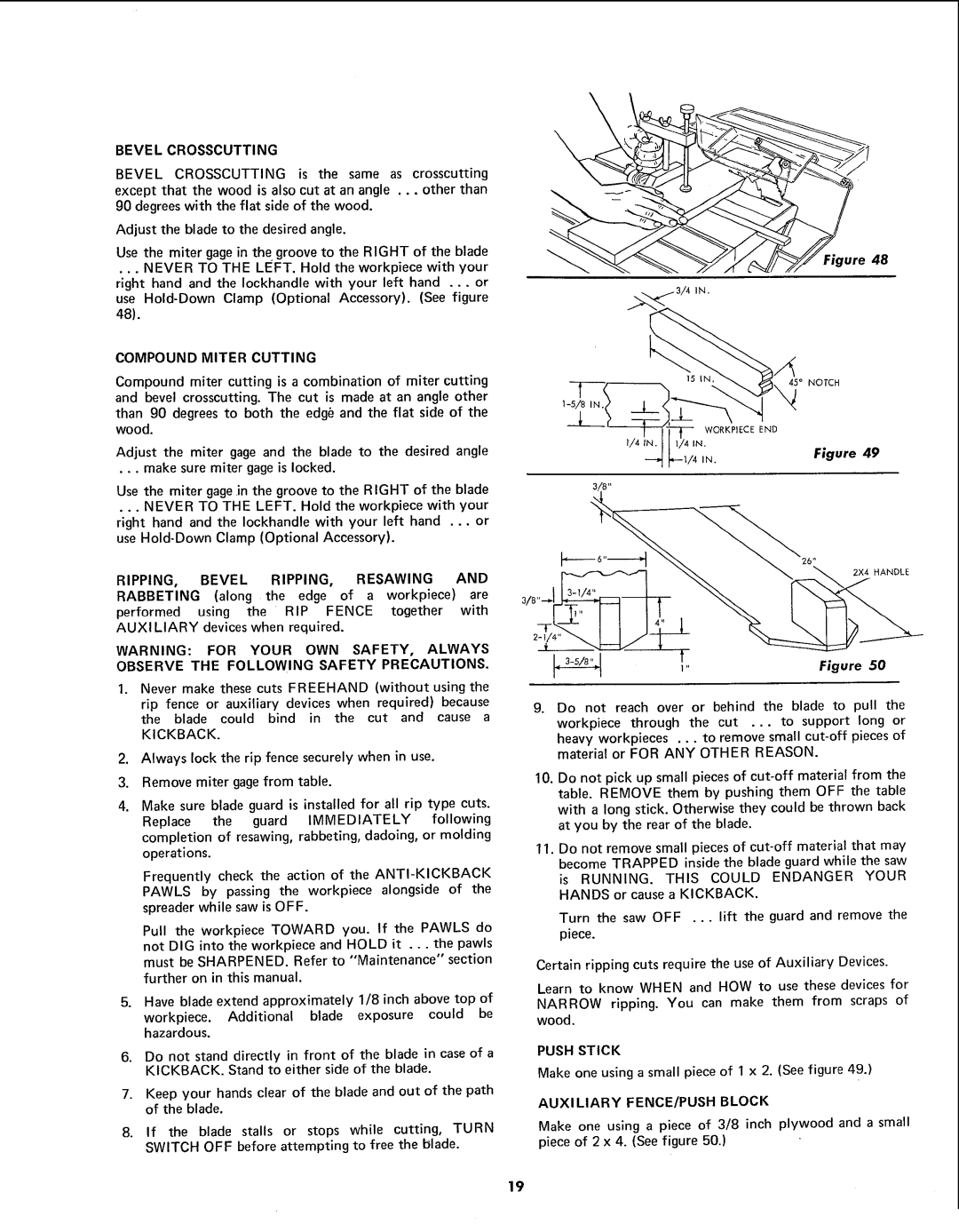

WORKPIECE | END |

I/4 IN. I/4 iN. | Figure 49 |

IN. |

2X4 HANDLE

Figure 50

g.Do not reach over or behind the blade to pull the

workpiece through the cut ... to support long or

heavy workpieces ... to remove small

10.Do not pick up small pieces of

11.Do not remove small pieces of

is RUNNING. THIS COULD ENDANGER YOUR

HANDS or cause a KICKBACK.

Turn the saw OFF ... lift the guard and remove the piece.

Certain ripping cuts require the use of Auxiliary Devices.

Learn to know WHEN and HOW to use these devices for NARROW ripping. You can make them from scraps of wood.

PUSH STICK

Make one using a small piece of 1 x 2. (See figure 49.)

AUXILIARY FENCE/PUSH BLOCK

Make one using a piece of 3/8 inch plywood and a small piece of 2 x 4. (See figure 50.)

19