Maintenance (continued)

139/150-Hour Maintenance

Maintenance after first | Ŷ Replace the spark plug annually: Use | Ŷ The valve clearance should be adjusted |

then every | only the type recommended in the | annually or every 135 hours. It is |

Ŷ Combustion chamber should be decar- | ”Specifications” section or an equivalent | highly recommended that this is |

bonized, and the valve clearance should | resistor type spark plug of the correct | done by a |

be adjusted. It is highly recommended | heat range. Set spark plug electrode | technician. |

that this is done by a | gap to 0.6 |

|

service technician. |

|

|

Valve Adjustment

1.Remove cylinder cover, rocker arm cover, and spark plug. Rotate the crankshaft while observing the piston through the spark plug opening. When the piston

is at the top of the compression stroke (TDC), the valves can be adjusted.

CAUTION!

ŶPerforming a valve adjustment incorrectly may cause hard starting and/or can damage the engine.

ŶIf you are unfamiliar with this engine or uncomfortable with this procedure, consult with an autho- rized Shindaiwa servicing dealer.

2.Loosen adjuster locknut so that the

2.5 mm Allen socket head adjustment screw can turn freely.

3.Insert 0.10 mm feeler gauge between valve stem tip and rocker arm.

4.Turn adjustment screw (clockwise = tighter,

5.While holding the adjustment screw in place with the Allen driver, tighten the locknut with a wrench.

6.Turn engine over several times, and returnthe to

7.Replace rocker arm cover gasket to assure proper sealing and install cover.

IMPORTANT!

If a new gasket is not available and/or the old gasket is not damaged, the old gasket may be reused. Never use cracked or dam- aged gaskets!

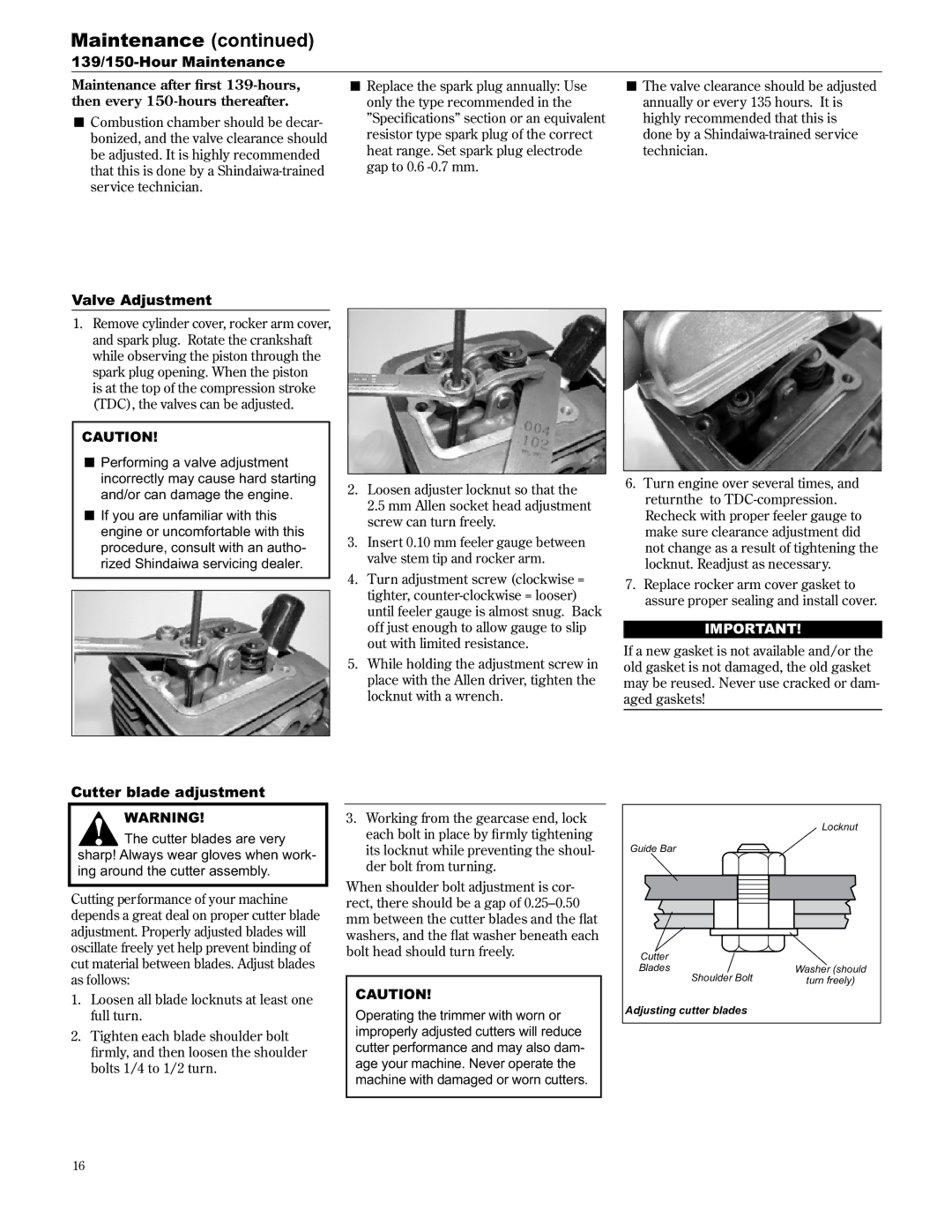

Cutter blade adjustment

WARNING!

The cutter blades are very sharp! Always wear gloves when work- ing around the cutter assembly.

Cutting performance of your machine depends a great deal on proper cutter blade adjustment. Properly adjusted blades will oscillate freely yet help prevent binding of cut material between blades. Adjust blades as follows:

1.Loosen all blade locknuts at least one full turn.

2.Tighten each blade shoulder bolt firmly, and then loosen the shoulder bolts 1/4 to 1/2 turn.

3.Working from the gearcase end, lock each bolt in place by firmly tightening its locknut while preventing the shoul- der bolt from turning.

When shoulder bolt adjustment is cor- rect, there should be a gap of

mmbetween the cutter blades and the flat washers, and the flat washer beneath each bolt head should turn freely.

CAUTION!

Operating the trimmer with worn or improperly adjusted cutters will reduce cutter performance and may also dam- age your machine. Never operate the machine with damaged or worn cutters.

| Locknut |

Guide Bar |

|

Cutter |

|

Blades | Washer (should |

Shoulder Bolt | turn freely) |

Adjusting cutter blades |

|

16