SB1024/SB1025/SB1026 | O P E R A T I O N | For Machines Mfg. Since 8/09 |

When the spindle speed range is changed, the direction of spindle rotation will reverse. ALWAYS know which way the spindle

is rotating before beginning the cutting operation.

Setting SB1024 Spindle Speed Range

1.Make sure that the spindle rotation is turned OFF and the spindle is at a complete stop.

2.Use the chart below to find the spindle speed range that includes the required spindle speed for your operation.

Model SB1024 Spindle Speed Ranges

Low Range | |

High Range |

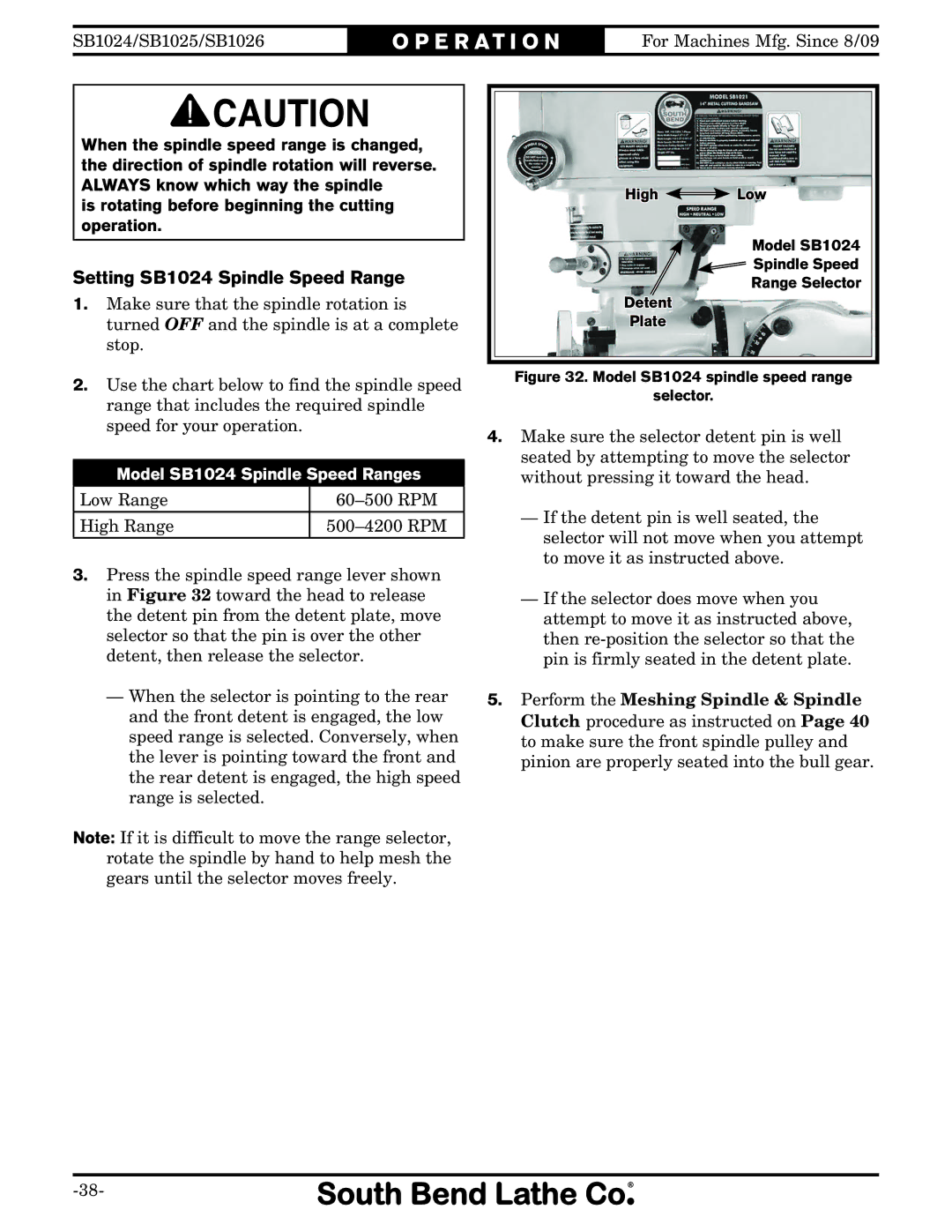

3.Press the spindle speed range lever shown in Figure 32 toward the head to release the detent pin from the detent plate, move selector so that the pin is over the other detent, then release the selector.

—When the selector is pointing to the rear and the front detent is engaged, the low speed range is selected. Conversely, when the lever is pointing toward the front and the rear detent is engaged, the high speed range is selected.

Note: If it is difficult to move the range selector, rotate the spindle by hand to help mesh the gears until the selector moves freely.

High![]()

![]()

![]() Low

Low

Model SB1024

Spindle Speed

Range Selector

Detent

Plate

Figure 32. Model SB1024 spindle speed range

selector.

4.Make sure the selector detent pin is well seated by attempting to move the selector without pressing it toward the head.

—If the detent pin is well seated, the selector will not move when you attempt to move it as instructed above.

—If the selector does move when you attempt to move it as instructed above, then

5.Perform the Meshing Spindle & Spindle Clutch procedure as instructed on Page 40 to make sure the front spindle pulley and pinion are properly seated into the bull gear.