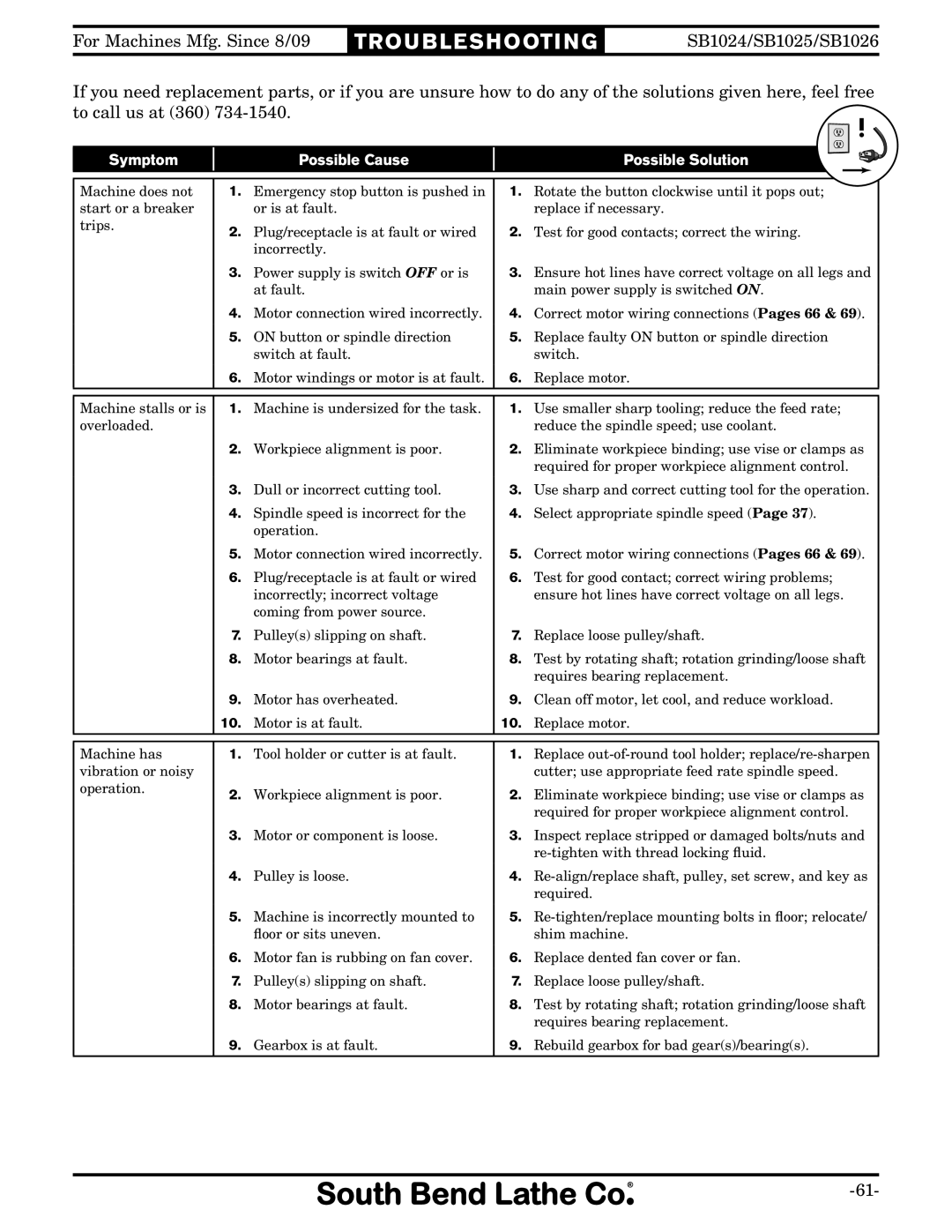

For Machines Mfg. Since 8/09 TR O U B L E S H O OTI N G SB1024/SB1025/SB1026

If you need replacement parts, or if you are unsure how to do any of the solutions given here, feel free | ||||

to call us at (360) |

| ! | ||

|

|

|

| |

Symptom |

| Possible Cause |

| Possible Solution |

Machine does not | 1. | Emergency stop button is pushed in | 1. | Rotate the button clockwise until it pops out; |

start or a breaker |

| or is at fault. |

| replace if necessary. |

trips. | 2. | Plug/receptacle is at fault or wired | 2. | Test for good contacts; correct the wiring. |

| ||||

|

| incorrectly. |

|

|

3.Power supply is switch OFF or is 3. Ensure hot lines have correct voltage on all legs and

at fault. | main power supply is switched ON. |

4.Motor connection wired incorrectly. 4. Correct motor wiring connections (Pages 66 & 69).

5. | ON button or spindle direction | 5. | Replace faulty ON button or spindle direction |

| switch at fault. |

| switch. |

6. | Motor windings or motor is at fault. | 6. | Replace motor. |

|

|

|

|

Machine stalls or is 1. | Machine is undersized for the task. | 1. | Use smaller sharp tooling; reduce the feed rate; |

overloaded. |

|

| reduce the spindle speed; use coolant. |

2.Workpiece alignment is poor.2. Eliminate workpiece binding; use vise or clamps as required for proper workpiece alignment control.

3.Dull or incorrect cutting tool.3. Use sharp and correct cutting tool for the operation.

4.Spindle speed is incorrect for the 4. Select appropriate spindle speed (Page 37). operation.

5.Motor connection wired incorrectly. 5. Correct motor wiring connections (Pages 66 & 69).

6.Plug/receptacle is at fault or wired 6. Test for good contact; correct wiring problems;

incorrectly; incorrect voltage | ensure hot lines have correct voltage on all legs. |

coming from power source. |

|

7. Pulley(s) slipping on shaft. | 7. Replace loose pulley/shaft. |

8.Motor bearings at fault.8. Test by rotating shaft; rotation grinding/loose shaft requires bearing replacement.

| 9. | Motor has overheated. | 9. | Clean off motor, let cool, and reduce workload. |

| 10. | Motor is at fault. | 10. | Replace motor. |

|

|

|

|

|

Machine has | 1. | Tool holder or cutter is at fault. | 1. | Replace |

vibration or noisy |

|

|

| cutter; use appropriate feed rate spindle speed. |

operation. | 2. | Workpiece alignment is poor. | 2. | Eliminate workpiece binding; use vise or clamps as |

| ||||

|

|

|

| required for proper workpiece alignment control. |

3.Motor or component is loose.3. Inspect replace stripped or damaged bolts/nuts and

4. Pulley is loose. | 4. |

| required. |

5.Machine is incorrectly mounted to 5.

| floor or sits uneven. |

| shim machine. |

6. | Motor fan is rubbing on fan cover. | 6. | Replace dented fan cover or fan. |

7. | Pulley(s) slipping on shaft. | 7. | Replace loose pulley/shaft. |

8.Motor bearings at fault.8. Test by rotating shaft; rotation grinding/loose shaft requires bearing replacement.

9. Gearbox is at fault. | 9. Rebuild gearbox for bad gear(s)/bearing(s). |