42 Milling Machine

Updates

Customer Service

Scope of Manual

Manual Feedback

Table of Contents

Parts

Features

About These Machines

Foreword

Capabilities

Front View Identification

Identification-front view Model SB1024 shown

Model SB1024 Belt Housing Headstock Identification

Model SB1024 belt housing and headstock identification

Model SB1025/SB1026 Belt Housing Headstock Identification

Model SB1024 42 Variable Speed Milling Machine Power Feed

Machine Specifications

Table Information

Model SB1025 42 Milling Machine Power Feed

80, 140, 220, 325 RPM

Model SB1026 42 Milling Machine Power Feed

High Range of Spindle Speeds

Basic Machine Safety

Understanding Risks of Machinery

F E T Y

Additional Milling Machine Safety

Preparation Overview

Things Youll Need

Unpacking

Inventory

Basic steps for removing rust preventative

Cleaning & Protecting

Before cleaning, gather the following

Location

Lifting & Moving

To lift and move the mill

Leveling

Leveling & Mounting

Bolting to Concrete Floors

Assembly

To install the ball handles

Ball Handles

Knee Crank

Front way cover installed

Way Covers

Power Connection

SB1025 220V 3-Phase

SB1024

SB1026

To test run the machine

Initial Lubrication

Test Run

To test the X-axis power feed unit and table limit switch

Spindle Break-In

Inspections Adjustments

To perform the spindle break-in procedure

Operation Overview

A typical milling operation, the operator does the following

Control Panel

Table Movement

Graduated Index Rings

Table Locks

Axis Power Feed

To operate the X-axis power feed

Head Movement

Tilting Head

Rotating Head

Tramming Spindle

To tram the spindle to the table

Tools Needed Qty

Place the parallel block directly under

Rotating Ram

Ram Movement

Moving Ram Back-and-Forth

Determining Spindle Speed

Setting Spindle Speed

Setting Spindle Speed Range

Setting SB1024 Spindle Speed Range

Model SB1024 Spindle Speed Ranges

Setting SB1025/SB1026 Spindle Speed Range

Model SB1025 Spindle Speed Ranges

Meshing Spindle & Spindle Clutch

Setting Spindle Speed

Setting SB1024 Spindle Speed

Setting SB1025/SB1026 Spindle Speed

F2/R2

Using the Coarse Downfeed Handle

Downfeed Controls

Manual Disengaged Position Auto-Downfeed Engaged Position

Using the Fine Downfeed Handwheel

Fine Downfeed Controls

Using the Auto-Downfeed System

To use the auto-downfeed system

Spindle Brake

= 0.006 in./rev = 0.0015 in./rev = 0.003 in./rev

Unloading Tooling

Loading/Unloading Tooling

Loading Tooling

Maintenance Schedule

Before Beginning Operations

Ongoing

Daily, After Operations

Month/Year

Lubrication

Unpainted & Machined Surfaces

Cleaning

Lubrication

Quill

Table Ways One-Shot Oiler

Speed Range Bearing Sleeve SB1024 Only

Headstock Gearing

Power Feed Gears

To lubricate the power feed gears

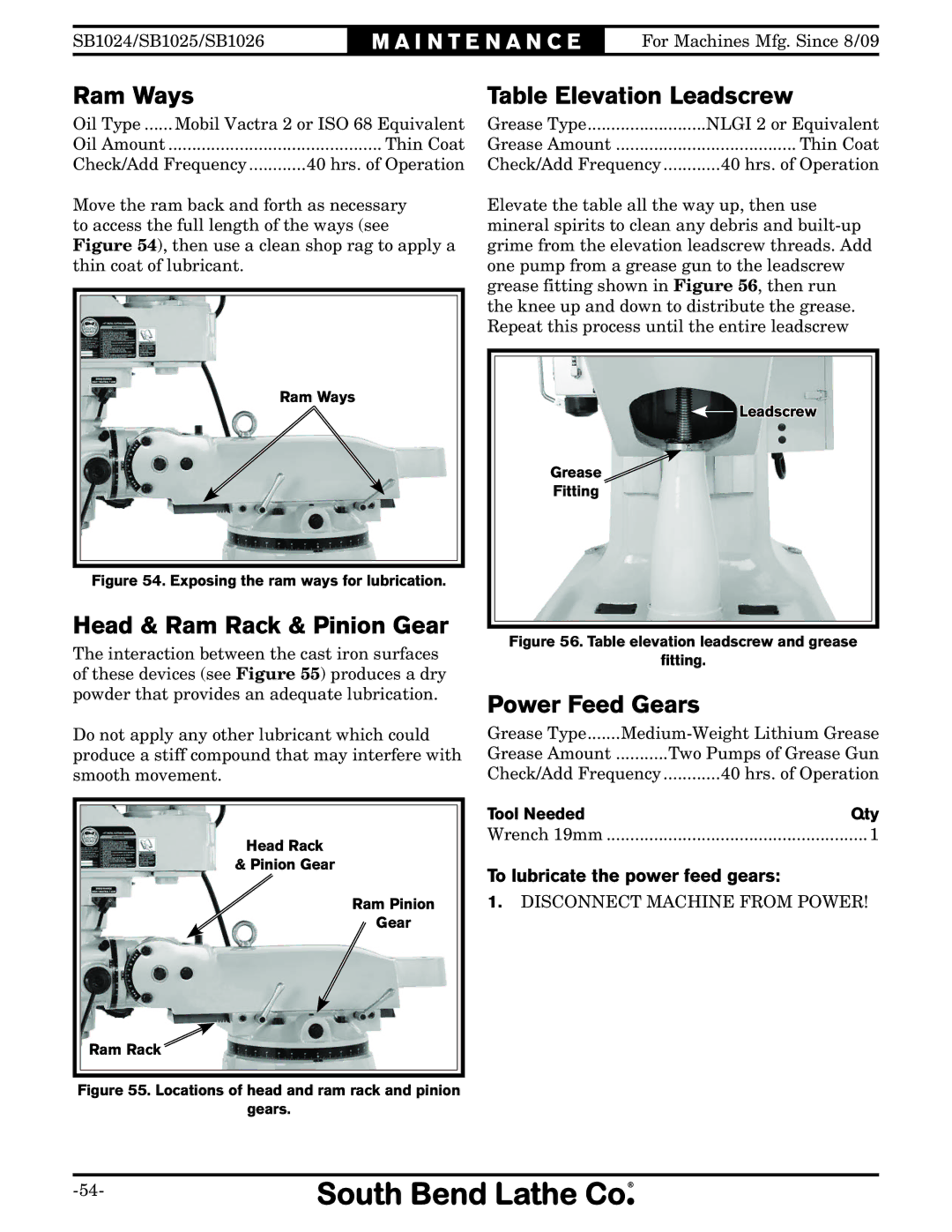

Ram Ways

Head & Ram Rack & Pinion Gear

Power feed ball handle removed Drive Gear Bevel Gear

Cleaning Coolant Reservoir

Cleaning

To clean out the coolant reservoir

Hazards

Machine Storage

Lubrication section beginning on

Adjusting Gibs

Disconnect Mill from Power Before Adjusting the Gibs

Adjusting Leadscrew Backlash

Longitudinal Leadscrew Backlash

Cross Leadscrew Backlash

Ball handle, rings, and key removed from Cross leadscrew

Symptom Possible Cause Possible Solution

TR O U B L E S H O OTI N G

Electrical Safety Instructions

Wiring Overview

Wiring Diagram Color KEY

SB1024/SB1026 Electrical Box

Box, See

SB1024/SB1026 Electrical Components

Control Panel Viewed From Behind See Figure

SB1024/SB1026 Electrical Component Pictures

Motor junction box

SB1025 Electrical Box

SB1025 Electrical Components

SB1025 Electrical Component Pictures

SB1025 Motor junction box

Headstock

Headstock Parts List

Description

Reverse Trip Ball Lever

Quill

SB1024 Gearbox

SB1024 Gearbox Parts List

Description

SB1025/SB1026 Gearbox

SB1025/SB1026 Gearbox Parts List

SB1024 Belt Housing

SB1024 Belt Housing Parts List

SB1025/SB1026 Belt Housing

SB1025/SB1026 Belt Housing Parts List

CAM Ring Screw M6-1 X

Ram

Ram Parts List

668

Column, Knee, & Saddle Parts List

Saddle GIB

709

Table Parts List

Leadscrew NUT Bracket

One-Shot Oiler

C D E F G H

SB1024/SB1026 Electrical Box & Control Panel

Electrical Box

SB1025 Electrical Box & Control Panel

Control Panel

Accessories

SB1024 Head Machine Labels

SB1024 Main Machine Labels

220V 1PH Label

SB1025/SB1026 Machine Labels

Page

R R a N T Y

Southbendlathe.com

![]() Leadscrew

Leadscrew![]()