SB1024/SB1025/SB1026 | S E R V I C E | For Machines Mfg. Since 8/09 |

Adjusting Gibs

Gibs are tapered lengths of metal that are sandwiched between two moving surfaces. Gibs control the gap between these surfaces and how they slide past one another. Correctly adjusting the gibs is critical to producing good milling results.

Tight gibs make table movement more accurate but stiff. Loose gibs make moving the table sloppy but easier to do. The goal of gib adjustment is to remove unnecessary sloppiness without causing the ways to bind.

Gibs are adjusted with a screw on each end of the gib, that move the tapered gib

DISCONNECT MILL FROM POWER BEFORE ADJUSTING THE GIBS!

Make sure all table and knee locks are loose. Then, loosen one gib adjustment screw and tighten the other the same amount to move the gib. Use the ball handles/crank to move the table/ knee until you feel a slight drag in that path of movement.

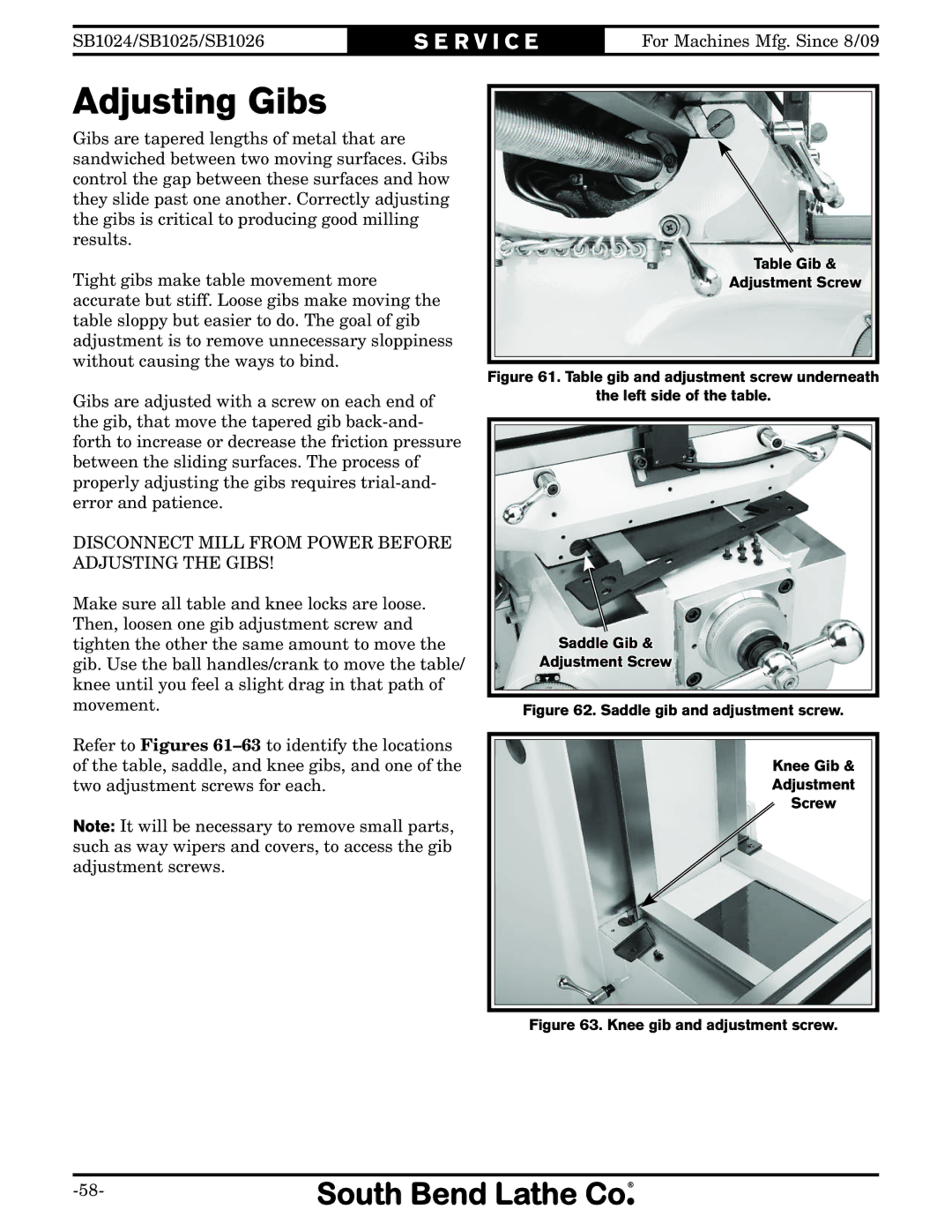

Refer to Figures

Note: It will be necessary to remove small parts, such as way wipers and covers, to access the gib adjustment screws.

Table Gib &

Adjustment Screw