For Machines Mfg. Since 8/09 | O P E R A T I O N | SB1024/SB1025/SB1026 |

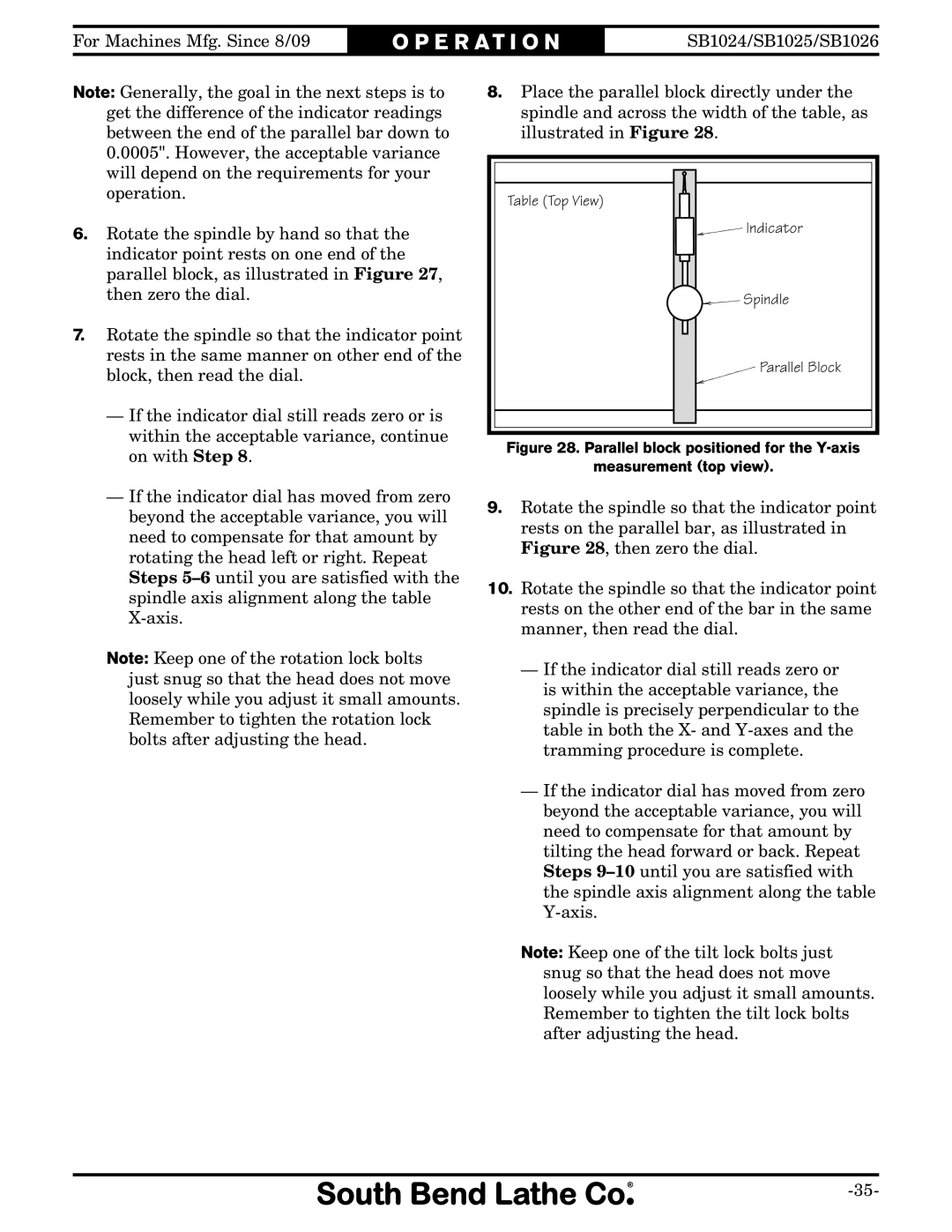

Note: Generally, the goal in the next steps is to | 8. Place the parallel block directly under the | |

| get the difference of the indicator readings | spindle and across the width of the table, as |

| between the end of the parallel bar down to | illustrated in Figure 28. |

| 0.0005". However, the acceptable variance |

|

| will depend on the requirements for your |

|

| operation. | Table (Top View) |

|

| |

6. | Rotate the spindle by hand so that the | Indicator |

| indicator point rests on one end of the |

|

| parallel block, as illustrated in Figure 27, |

|

| then zero the dial. | Spindle |

7. | Rotate the spindle so that the indicator point |

|

| rests in the same manner on other end of the | Parallel Block |

| block, then read the dial. | |

|

| |

| — If the indicator dial still reads zero or is |

|

| within the acceptable variance, continue | Figure 28. Parallel block positioned for the |

| on with Step 8. | |

| measurement (top view). | |

|

| |

— If the indicator dial has moved from zero | 9. | Rotate the spindle so that the indicator point | |

beyond the acceptable variance, you will | |||

| rests on the parallel bar, as illustrated in | ||

need to compensate for that amount by |

| ||

| Figure 28, then zero the dial. | ||

rotating the head left or right. Repeat |

| ||

|

| ||

Steps | 10. | Rotate the spindle so that the indicator point | |

spindle axis alignment along the table | |||

|

|

rests on the other end of the bar in the same | ||

manner, then read the dial. | ||

| ||

Note: Keep one of the rotation lock bolts | — If the indicator dial still reads zero or | |

just snug so that the head does not move | ||

is within the acceptable variance, the | ||

loosely while you adjust it small amounts. | ||

spindle is precisely perpendicular to the | ||

Remember to tighten the rotation lock | ||

table in both the X- and | ||

bolts after adjusting the head. | ||

tramming procedure is complete. | ||

| ||

| — If the indicator dial has moved from zero | |

| beyond the acceptable variance, you will | |

| need to compensate for that amount by | |

| tilting the head forward or back. Repeat | |

| Steps | |

| the spindle axis alignment along the table | |

| ||

| Note: Keep one of the tilt lock bolts just | |

| snug so that the head does not move | |

| loosely while you adjust it small amounts. | |

| Remember to tighten the tilt lock bolts | |

| after adjusting the head. |