14" | O P E R A T I O N | For Machines Mfg. Since 5/11 |

|

|

|

Aligning Tailstock to Spindle Centerline

This is an essential adjustment that should be verified or performed each time the tailstock is used to turn concentric workpieces between centers or immediately after offsetting the tailstock when turning a taper. If the tailstock is not aligned with the spindle centerline when it is supposed to be, turning results will be inaccurate along the length of the workpiece.

Items Needed | Qty |

Hex Wrench 6mm | 1 |

Wrench 17mm | 1 |

Round Stock 2" x 6" | 2 |

Precision Level | 1 |

To align the tailstock to the spindle centerline:

1.Use the precision level to make sure the bedway is level from

—If the bedway is not level, correct this condition before continuing with this procedure (refer to Leveling & Mounting on Page 23).

2.Center drill both ends of one piece of round stock, then set it aside for use in Step 5.

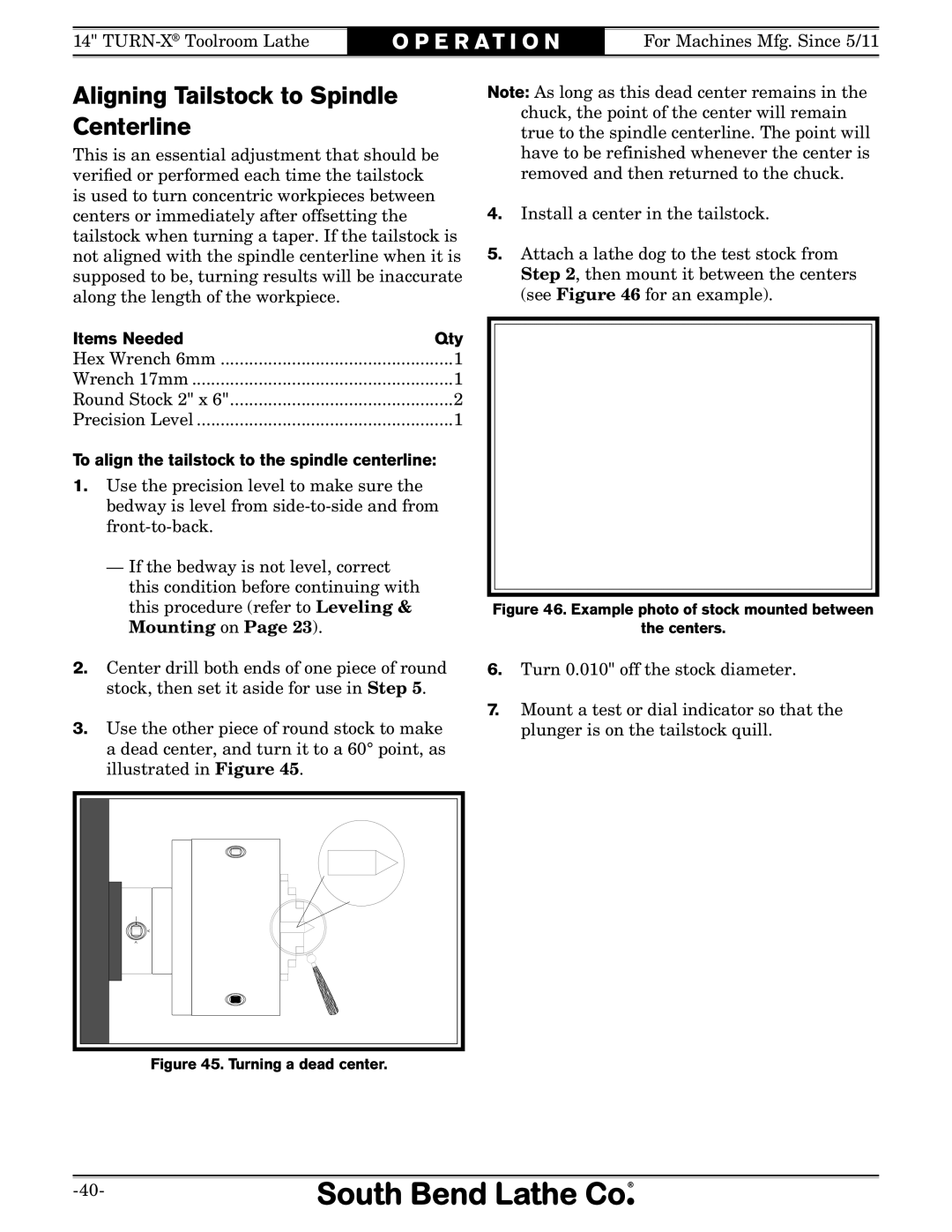

3.Use the other piece of round stock to make a dead center, and turn it to a 60° point, as illustrated in Figure 45.

Figure 45.

Turning a dead center.

Turning a dead center.

Note: As long as this dead center remains in the chuck, the point of the center will remain true to the spindle centerline. The point will have to be refinished whenever the center is removed and then returned to the chuck.

4.Install a center in the tailstock.

5.Attach a lathe dog to the test stock from Step 2, then mount it between the centers (see Figure 46 for an example).

Figure 46. Example photo of stock mounted between

the centers.

6.Turn 0.010" off the stock diameter.

7.Mount a test or dial indicator so that the plunger is on the tailstock quill.