For Machines Mfg. Since 5/11 | O P E R A T I O N | 14" |

|

|

|

Setting Spindle Speed of 1600 RPM

1.Make sure the spindle is completely stopped and the spindle lever is in the OFF (middle) position.

2.Turn the motor switch to the high (right) position.

Note: The blue color of the motor switch high position corresponds to the column in the

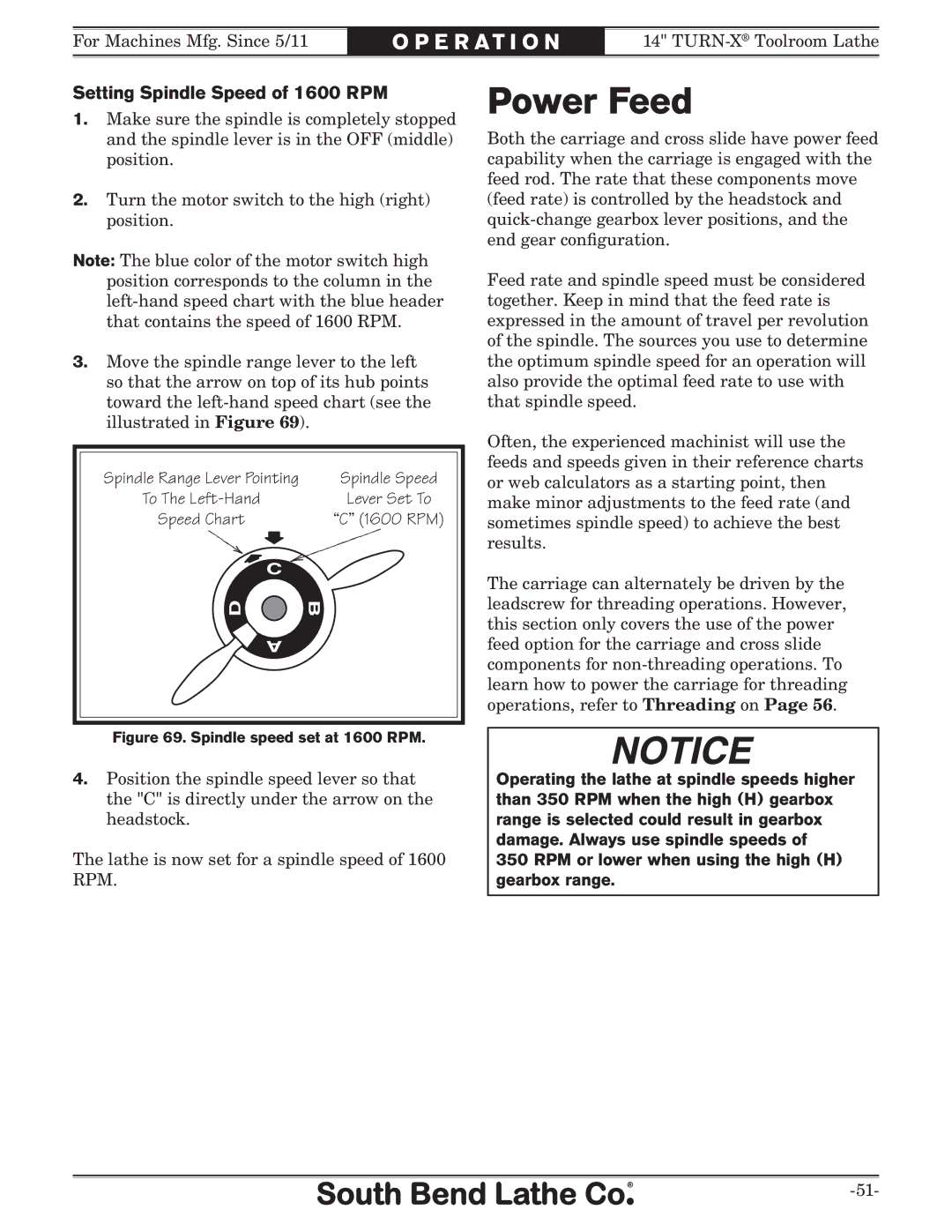

3.Move the spindle range lever to the left so that the arrow on top of its hub points toward the

Spindle Range Lever Pointing | Spindle Speed |

To The | Lever Set To |

Speed Chart | “C” (1600 RPM) |

C |

|

D | B |

A |

|

Figure 69. Spindle speed set at 1600 RPM.

4.Position the spindle speed lever so that the "C" is directly under the arrow on the headstock.

The lathe is now set for a spindle speed of 1600 RPM.

Power Feed

Both the carriage and cross slide have power feed capability when the carriage is engaged with the feed rod. The rate that these components move (feed rate) is controlled by the headstock and

Feed rate and spindle speed must be considered together. Keep in mind that the feed rate is expressed in the amount of travel per revolution of the spindle. The sources you use to determine the optimum spindle speed for an operation will also provide the optimal feed rate to use with that spindle speed.

Often, the experienced machinist will use the feeds and speeds given in their reference charts or web calculators as a starting point, then make minor adjustments to the feed rate (and sometimes spindle speed) to achieve the best results.

The carriage can alternately be driven by the leadscrew for threading operations. However, this section only covers the use of the power feed option for the carriage and cross slide components for

Operating the lathe at spindle speeds higher than 350 RPM when the high (H) gearbox range is selected could result in gearbox damage. Always use spindle speeds of