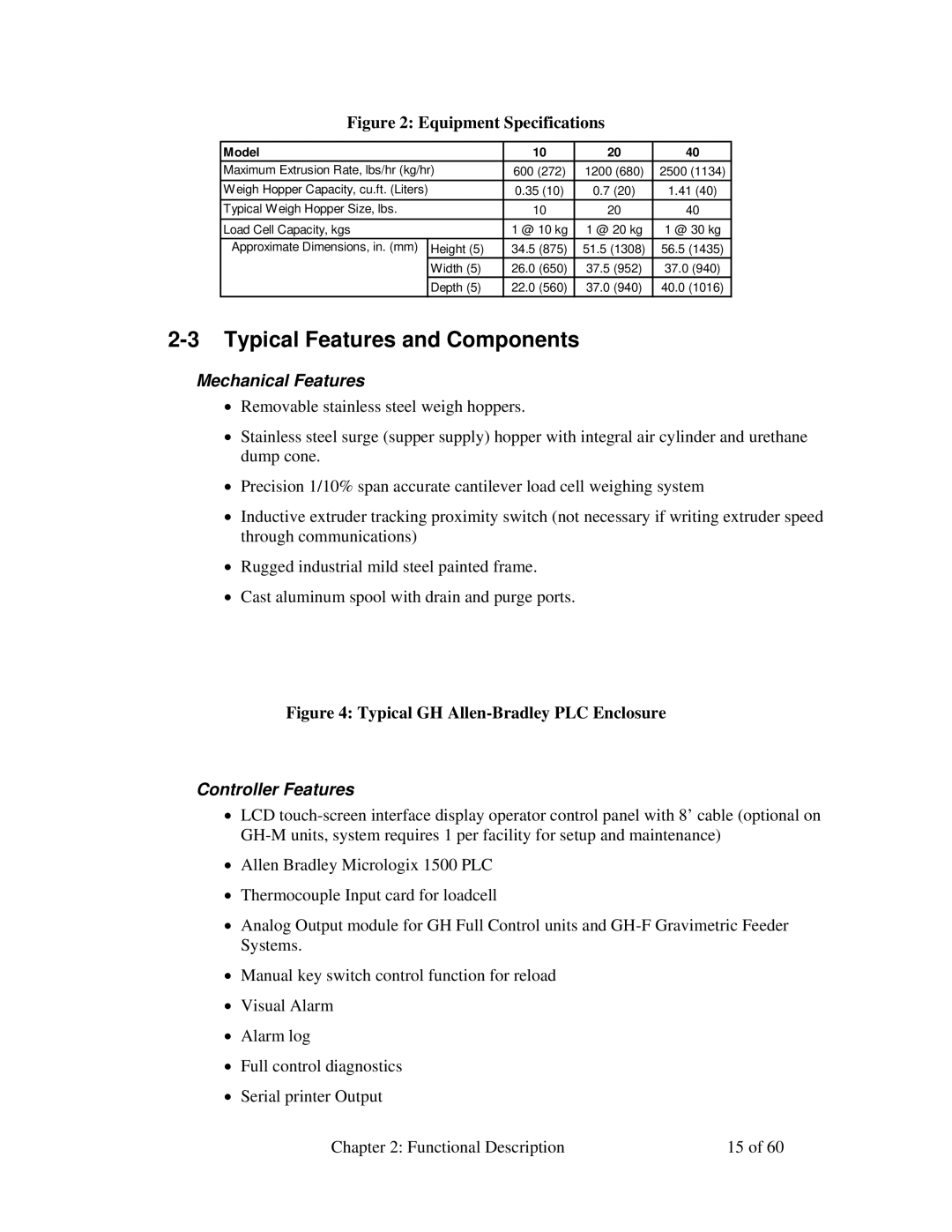

Figure 2: Equipment Specifications

Model | 10 | 20 | 40 | ||

Maximum Extrusion Rate, lbs/hr (kg/hr) | 600 (272) | 1200 (680) | 2500 (1134) | ||

Weigh Hopper Capacity, cu.ft. (Liters) | 0.35 (10) | 0.7 | (20) | 1.41 (40) | |

Typical Weigh Hopper Size, lbs. | 10 | 20 | 40 | ||

Load Cell Capacity, kgs | 1 @ 10 kg | 1 @ 20 kg | 1 @ 30 kg | ||

Approximate Dimensions, in. (mm) | Height (5) | 34.5 (875) | 51.5 (1308) | 56.5 (1435) | |

| Width (5) | 26.0 (650) | 37.5 | (952) | 37.0 (940) |

| Depth (5) | 22.0 (560) | 37.0 | (940) | 40.0 (1016) |

2-3 Typical Features and Components

Mechanical Features

•Removable stainless steel weigh hoppers.

•Stainless steel surge (supper supply) hopper with integral air cylinder and urethane dump cone.

•Precision 1/10% span accurate cantilever load cell weighing system

•Inductive extruder tracking proximity switch (not necessary if writing extruder speed through communications)

•Rugged industrial mild steel painted frame.

•Cast aluminum spool with drain and purge ports.

Figure 4: Typical GH Allen-Bradley PLC Enclosure

Controller Features

•LCD

•Allen Bradley Micrologix 1500 PLC

•Thermocouple Input card for loadcell

•Analog Output module for GH Full Control units and

•Manual key switch control function for reload

•Visual Alarm

•Alarm log

•Full control diagnostics

•Serial printer Output

Chapter 2: Functional Description | 15 of 60 |