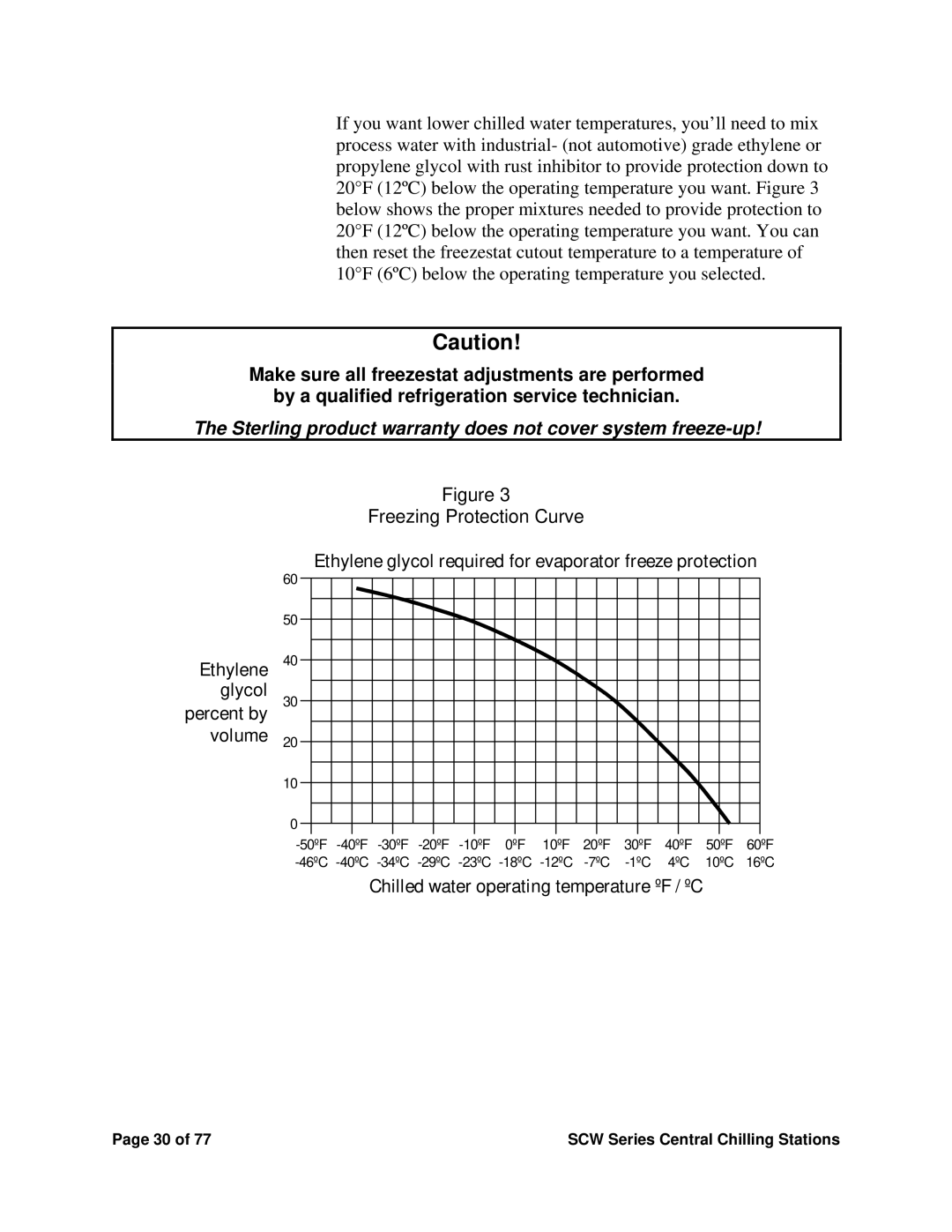

If you want lower chilled water temperatures, you’ll need to mix process water with industrial- (not automotive) grade ethylene or propylene glycol with rust inhibitor to provide protection down to 20°F (12ºC) below the operating temperature you want. Figure 3 below shows the proper mixtures needed to provide protection to 20°F (12ºC) below the operating temperature you want. You can then reset the freezestat cutout temperature to a temperature of 10°F (6ºC) below the operating temperature you selected.

Caution!

Make sure all freezestat adjustments are performed

by a qualified refrigeration service technician.

The Sterling product warranty does not cover system

Figure 3

Freezing Protection Curve

Ethylene glycol required for evaporator freeze protection

| 60 |

|

|

|

|

|

|

|

|

|

|

|

| 50 |

|

|

|

|

|

|

|

|

|

|

|

Ethylene | 40 |

|

|

|

|

|

|

|

|

|

|

|

glycol | 30 |

|

|

|

|

|

|

|

|

|

|

|

percent by |

|

|

|

|

|

|

|

|

|

|

| |

volume | 20 |

|

|

|

|

|

|

|

|

|

|

|

| 10 |

|

|

|

|

|

|

|

|

|

|

|

| 0 |

|

|

|

|

|

|

|

|

|

|

|

| 0ºF | 10ºF | 20ºF | 30ºF | 40ºF | 50ºF | 60ºF | |||||

| 4ºC | 10ºC | 16ºC |

Chilled water operating temperature ºF / ºC

Page 30 of 77 | SCW Series Central Chilling Stations |