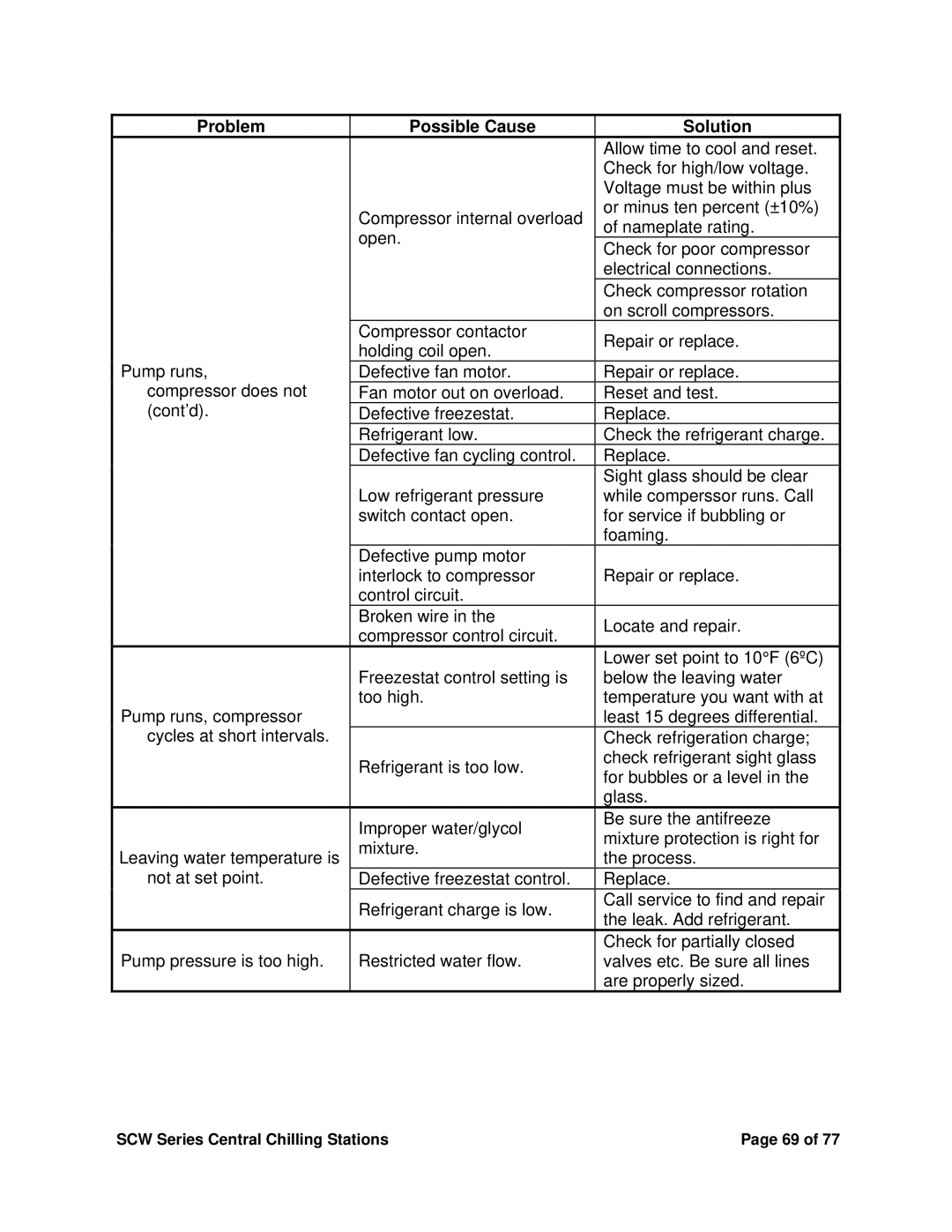

Problem | Possible Cause | Solution | |

|

| Allow time to cool and reset. | |

|

| Check for high/low voltage. | |

|

| Voltage must be within plus | |

| Compressor internal overload | or minus ten percent (±10%) | |

| of nameplate rating. | ||

| open. | ||

| Check for poor compressor | ||

|

| ||

|

| electrical connections. | |

|

| Check compressor rotation | |

|

| on scroll compressors. | |

| Compressor contactor | Repair or replace. | |

| holding coil open. | ||

Pump runs, |

| ||

Defective fan motor. | Repair or replace. | ||

compressor does not | Fan motor out on overload. | Reset and test. | |

(cont’d). | Defective freezestat. | Replace. | |

| Refrigerant low. | Check the refrigerant charge. | |

| Defective fan cycling control. | Replace. | |

| Low refrigerant pressure | Sight glass should be clear | |

| while comperssor runs. Call | ||

| switch contact open. | for service if bubbling or | |

|

| foaming. | |

| Defective pump motor | Repair or replace. | |

| interlock to compressor | ||

| control circuit. |

| |

| Broken wire in the | Locate and repair. | |

| compressor control circuit. | ||

|

| ||

| Freezestat control setting is | Lower set point to 10°F (6ºC) | |

| below the leaving water | ||

Pump runs, compressor | too high. | temperature you want with at | |

| least 15 degrees differential. | ||

cycles at short intervals. |

| Check refrigeration charge; | |

| Refrigerant is too low. | check refrigerant sight glass | |

| for bubbles or a level in the | ||

|

| ||

|

| glass. | |

| Improper water/glycol | Be sure the antifreeze | |

| mixture protection is right for | ||

Leaving water temperature is | mixture. | ||

the process. | |||

| |||

not at set point. | Defective freezestat control. | Replace. | |

| Refrigerant charge is low. | Call service to find and repair | |

| the leak. Add refrigerant. | ||

|

| ||

Pump pressure is too high. | Restricted water flow. | Check for partially closed | |

valves etc. Be sure all lines | |||

|

| are properly sized. |

SCW Series Central Chilling Stations | Page 69 of 77 |