4-11 Control Nozzle

All SCW Series chilling station evaporators have two control nozzles. The flow switch, freezestat, and flush port are located in the control nozzle. Pressure gages are mounted in the control nozzles to aid in achieving proper flow through the evaporator and balancing flows.

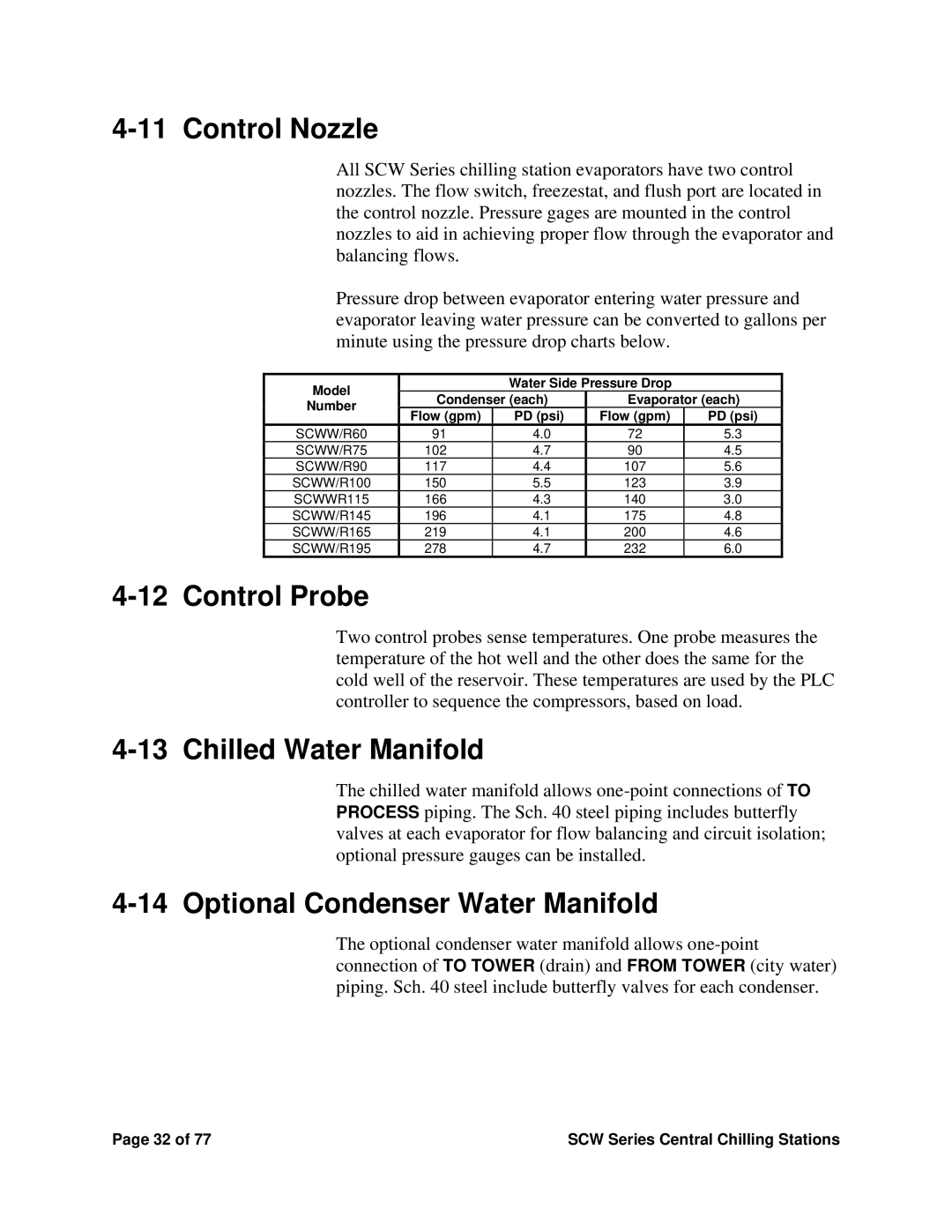

Pressure drop between evaporator entering water pressure and evaporator leaving water pressure can be converted to gallons per minute using the pressure drop charts below.

Model |

| Water Side Pressure Drop |

| ||

Condenser (each) | Evaporator (each) | ||||

Number | |||||

Flow (gpm) | PD (psi) | Flow (gpm) | PD (psi) | ||

| |||||

SCWW/R60 | 91 | 4.0 | 72 | 5.3 | |

SCWW/R75 | 102 | 4.7 | 90 | 4.5 | |

SCWW/R90 | 117 | 4.4 | 107 | 5.6 | |

SCWW/R100 | 150 | 5.5 | 123 | 3.9 | |

SCWWR115 | 166 | 4.3 | 140 | 3.0 | |

SCWW/R145 | 196 | 4.1 | 175 | 4.8 | |

SCWW/R165 | 219 | 4.1 | 200 | 4.6 | |

SCWW/R195 | 278 | 4.7 | 232 | 6.0 | |

4-12 Control Probe

Two control probes sense temperatures. One probe measures the temperature of the hot well and the other does the same for the cold well of the reservoir. These temperatures are used by the PLC controller to sequence the compressors, based on load.

4-13 Chilled Water Manifold

The chilled water manifold allows

4-14 Optional Condenser Water Manifold

The optional condenser water manifold allows

Page 32 of 77 | SCW Series Central Chilling Stations |