9-3 Evaporator Maintenance

The evaporator(s) may be accessed for

9-4 Pump Motor Seal

Pump seals require water for lubrication, so the pump(s) must never be run dry. Always fill the tank before attempting to operate the pump(s). Seal failures usually follow a period of dry operation of the pump.

9-5 Makeup Valve

Periodically inspect the water makeup valve assembly for proper operation. If the valve no longer shuts off completely or reliably, replace it. The plastic ball float should be buoyant for proper operation.

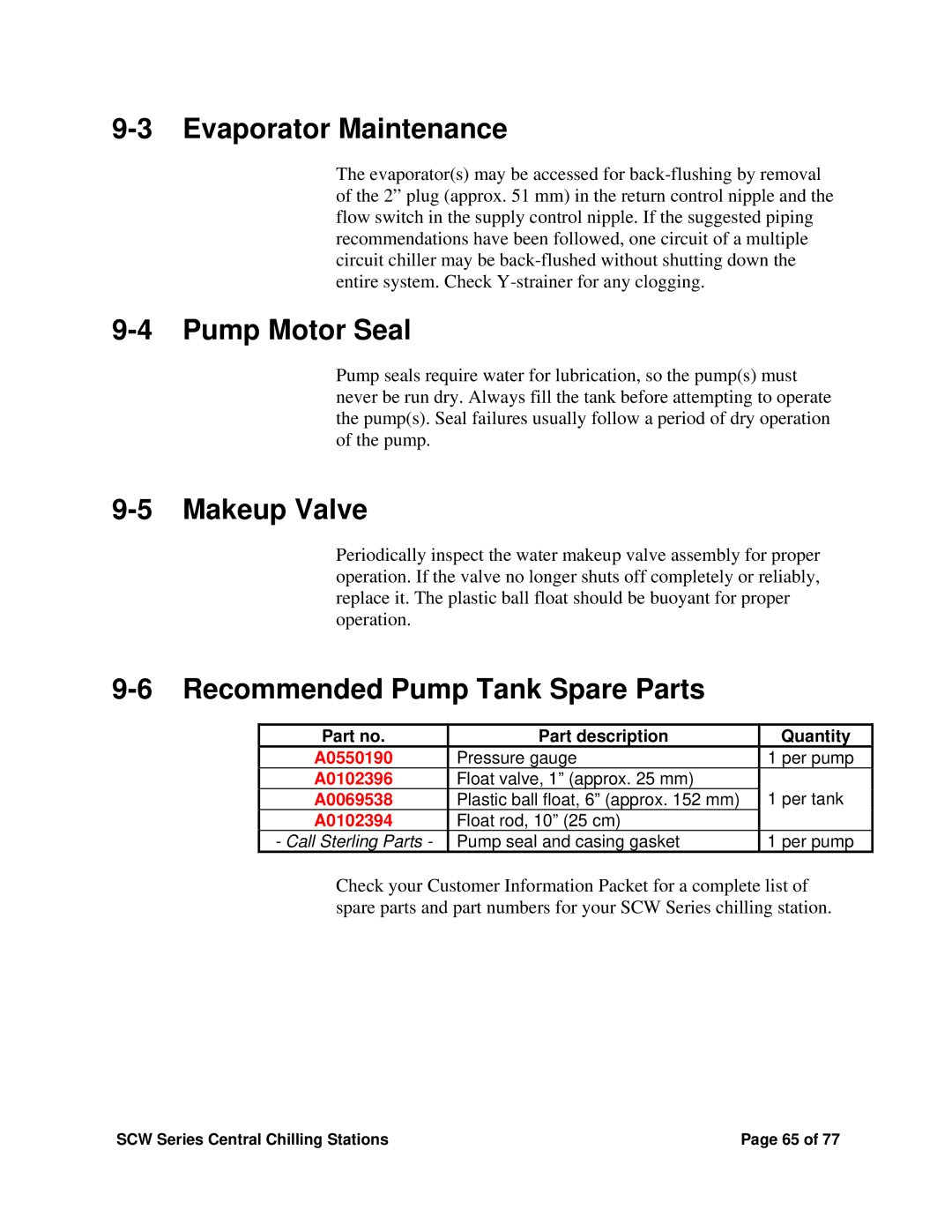

9-6 Recommended Pump Tank Spare Parts

Part no. | Part description | Quantity |

A0550190 | Pressure gauge | 1 per pump |

A0102396 | Float valve, 1” (approx. 25 mm) | 1 per tank |

A0069538 | Plastic ball float, 6” (approx. 152 mm) | |

A0102394 | Float rod, 10” (25 cm) |

|

- Call Sterling Parts - | Pump seal and casing gasket | 1 per pump |

Check your Customer Information Packet for a complete list of spare parts and part numbers for your SCW Series chilling station.

SCW Series Central Chilling Stations | Page 65 of 77 |