5 - 4 MOW TO REASSEMBLE

0 Precaution in reassembling |

|

|

|

Every andeachpartshouldbe cleaned thoroughly. Especially, payutmost care andattentiontothe clean- | 7 | ||

liness of the piston, cylinder, crankshaft, connecting rod and bearings. |

| ||

Scrapecompletelyoffcarbonsfrom | the cylinderheadand the upper part of the piston; especially the |

| |

carbon adhered in the groove of the piston ring should be carefully and completely taken out. |

| ||

Carefully check the lip portion of every oil seal. If faulty one is found, replace it without any hesitation. |

| ||

Apply enough oil to thelip portion of the oil seal when reassembling. |

| ||

Replace all the gaskets with new ones. |

|

| |

Replace the key, pin, bolt, nuts, etcwith. new one, if necessary. |

| ||

Whenever tightening torque is specified, conform to the specified figures. |

| ||

Apply oil to therevolutionary parts and friction surfaces, when reassembling. |

| ||

Check and adjust the clearances of various portions and thenreassemble. |

| ||

When some main portions are assembled in the course of reassembling, turn or move the gadgets by hand |

| ||

and pay attention to thefrictional noise and resistance. |

| ||

~Sequesnceand precautionsin reassembling | r |

| |

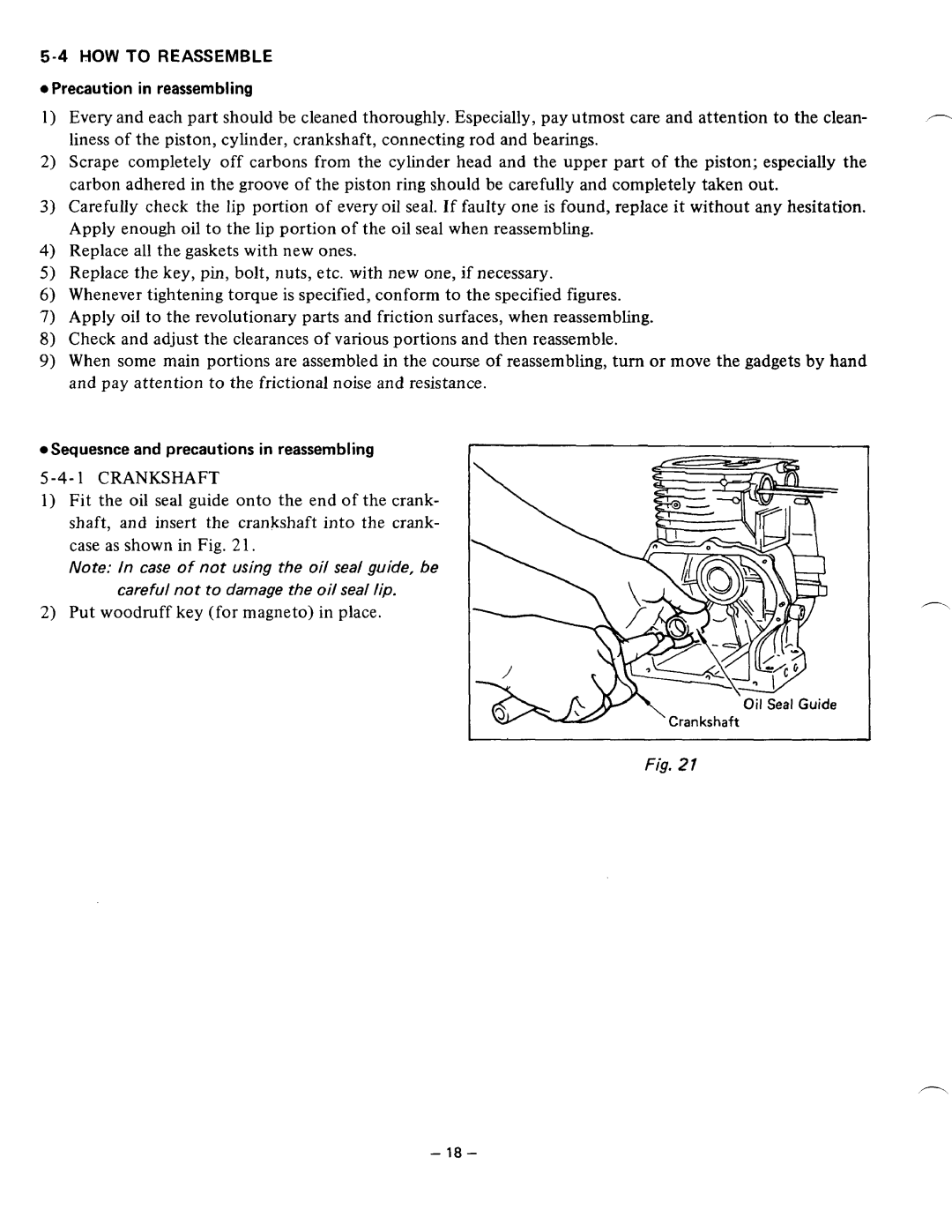

5-4- 1 CRANKSHAFT

1)Fit the oilseal guide onto the end of the crank-

shaft,andinsertthecrankshaft intothe crank- case as shown in Fig. 21.

Note: In case of not using the oil seal guide, be careful not to damage the oil seal lip.

2)Put woodruff key (for magneto) in place.

Fig. 21

- l a -