All installations and services must be performed by qualified service personnel.

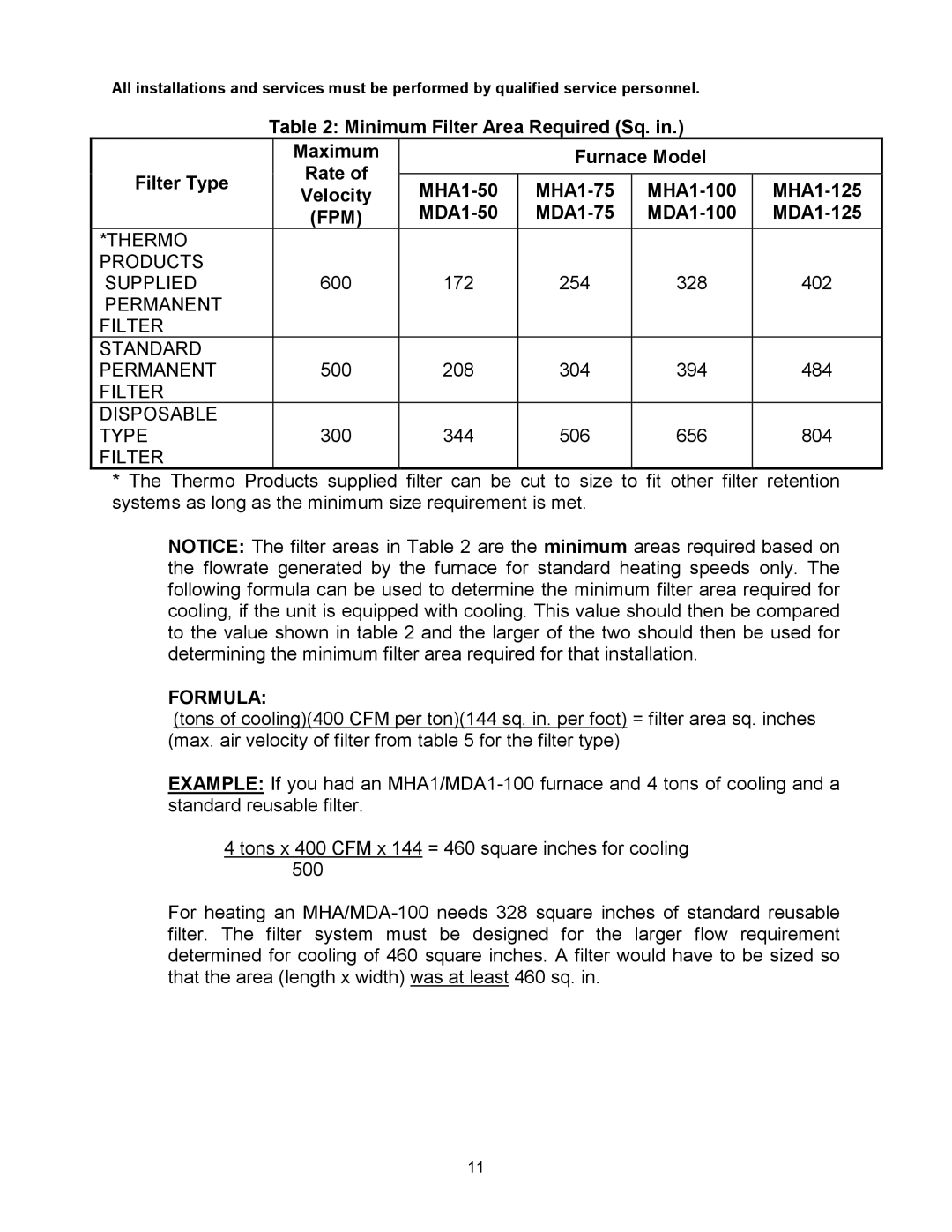

Table 2: Minimum Filter Area Required (Sq. in.)

| Maximum |

| Furnace Model |

| ||

Filter Type | Rate of |

|

|

|

| |

Velocity | ||||||

| ||||||

| (FPM) |

| ||||

*THERMO |

|

|

|

|

| |

PRODUCTS |

|

|

|

|

| |

SUPPLIED | 600 | 172 | 254 | 328 | 402 | |

PERMANENT |

|

|

|

|

| |

FILTER |

|

|

|

|

| |

STANDARD |

|

|

|

|

| |

PERMANENT | 500 | 208 | 304 | 394 | 484 | |

FILTER |

|

|

|

|

| |

DISPOSABLE |

|

|

|

|

| |

TYPE | 300 | 344 | 506 | 656 | 804 | |

FILTER |

|

|

|

|

| |

*The Thermo Products supplied filter can be cut to size to fit other filter retention systems as long as the minimum size requirement is met.

NOTICE: The filter areas in Table 2 are the minimum areas required based on the flowrate generated by the furnace for standard heating speeds only. The following formula can be used to determine the minimum filter area required for cooling, if the unit is equipped with cooling. This value should then be compared to the value shown in table 2 and the larger of the two should then be used for determining the minimum filter area required for that installation.

FORMULA:

(tons of cooling)(400 CFM per ton)(144 sq. in. per foot) = filter area sq. inches (max. air velocity of filter from table 5 for the filter type)

EXAMPLE: If you had an

4 tons x 400 CFM x 144 = 460 square inches for cooling 500

For heating an

11