Limitorque MX DeviceNet Field Unit FCD

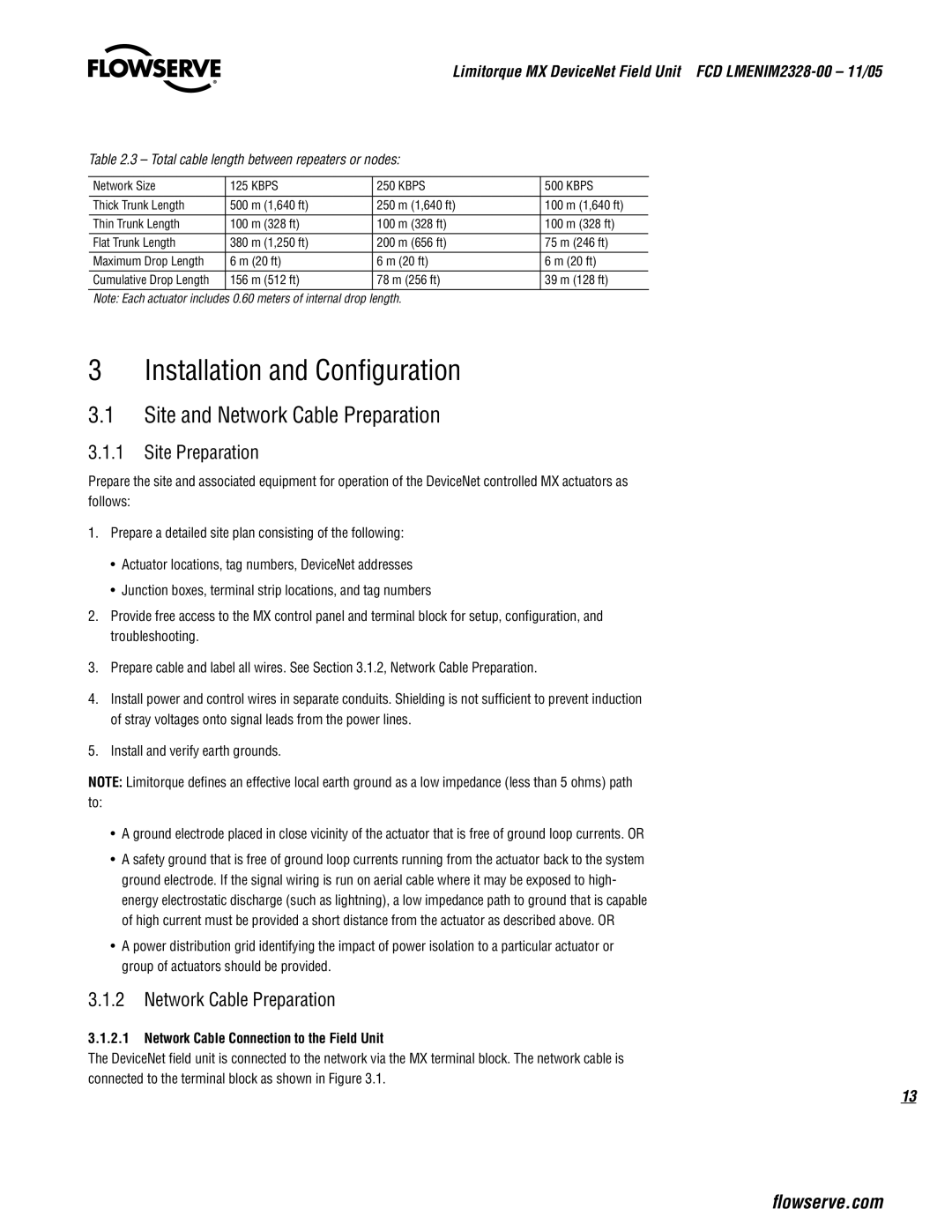

Table 2.3 – Total cable length between repeaters or nodes:

Network Size | 125 KBPS | 250 KBPS | 500 KBPS |

|

|

|

|

Thick Trunk Length | 500 m (1,640 ft) | 250 m (1,640 ft) | 100 m (1,640 ft) |

|

|

|

|

Thin Trunk Length | 100 m (328 ft) | 100 m (328 ft) | 100 m (328 ft) |

|

|

|

|

Flat Trunk Length | 380 m (1,250 ft) | 200 m (656 ft) | 75 m (246 ft) |

|

|

|

|

Maximum Drop Length | 6 m (20 ft) | 6 m (20 ft) | 6 m (20 ft) |

|

|

|

|

Cumulative Drop Length | 156 m (512 ft) | 78 m (256 ft) | 39 m (128 ft) |

|

|

|

|

Note: Each actuator includes 0.60 meters of internal drop length.

3 Installation and Configuration

3.1Site and Network Cable Preparation

3.1.1Site Preparation

Prepare the site and associated equipment for operation of the DeviceNet controlled MX actuators as follows:

1.Prepare a detailed site plan consisting of the following:

•Actuator locations, tag numbers, DeviceNet addresses

•Junction boxes, terminal strip locations, and tag numbers

2.Provide free access to the MX control panel and terminal block for setup, configuration, and troubleshooting.

3.Prepare cable and label all wires. See Section 3.1.2, Network Cable Preparation.

4.Install power and control wires in separate conduits. Shielding is not sufficient to prevent induction of stray voltages onto signal leads from the power lines.

5.Install and verify earth grounds.

NOTE: Limitorque defines an effective local earth ground as a low impedance (less than 5 ohms) path to:

•A ground electrode placed in close vicinity of the actuator that is free of ground loop currents. OR

•A safety ground that is free of ground loop currents running from the actuator back to the system ground electrode. If the signal wiring is run on aerial cable where it may be exposed to high- energy electrostatic discharge (such as lightning), a low impedance path to ground that is capable of high current must be provided a short distance from the actuator as described above. OR

•A power distribution grid identifying the impact of power isolation to a particular actuator or group of actuators should be provided.

3.1.2Network Cable Preparation

3.1.2.1Network Cable Connection to the Field Unit

The DeviceNet field unit is connected to the network via the MX terminal block. The network cable is connected to the terminal block as shown in Figure 3.1.

13

flowserve.com