7. Venting and Combustion Air

WARNING: The vent must be installed in accordance with national and local regulations. Failure to provide proper venting could result in death, serious injury and/or property damage. This unit must be installed with a vent to the outside of the building. Safe operation of any

WARNING: Units installed in multiples require individual vent pipe runs and vent caps. Manifolding of vent runs is not permitted due to possible recirculation of combustion products into the building and back pressure effects on the combustion air proving switch.

Venting must be in accordance with the National Fuel Gas Code Z223.1 or CAN/CGA B149.1 and B149.2, Installation Code for Gas Burning Appliances and Equipment, and all local codes. Local requirements supersede national requirements. Combustion air for this heater may be either taken from the space or may be ducted from the outside using the

concentric adapter combustion air/vent system. Flue products must always be vented to the outdoors.

Installation should be done by a qualified agency in accordance with these instructions. The qualified service agency installing the vent or vent/combustion air system is responsible for the installation.

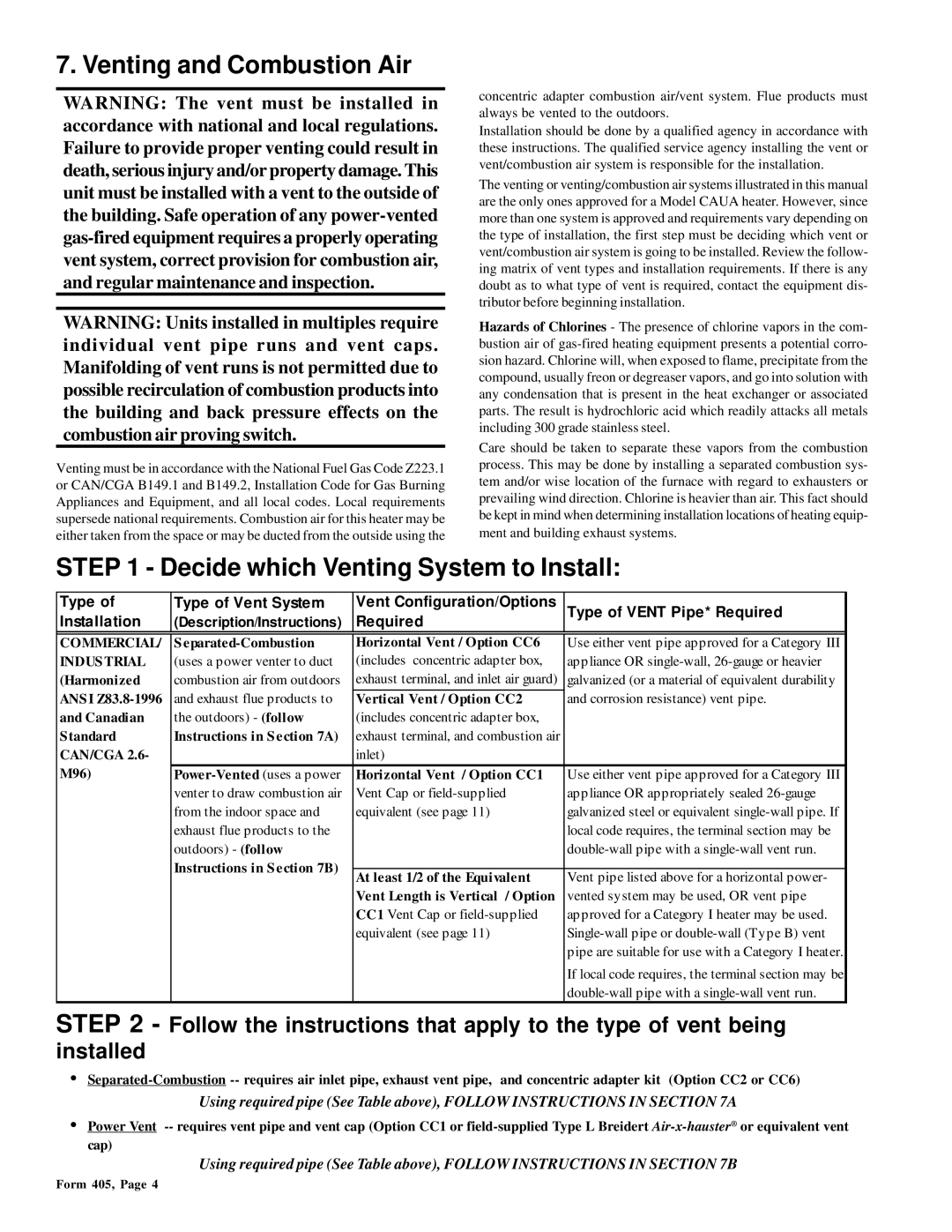

The venting or venting/combustion air systems illustrated in this manual are the only ones approved for a Model CAUA heater. However, since more than one system is approved and requirements vary depending on the type of installation, the first step must be deciding which vent or vent/combustion air system is going to be installed. Review the follow- ing matrix of vent types and installation requirements. If there is any doubt as to what type of vent is required, contact the equipment dis- tributor before beginning installation.

Hazards of Chlorines - The presence of chlorine vapors in the com- bustion air of

Care should be taken to separate these vapors from the combustion process. This may be done by installing a separated combustion sys- tem and/or wise location of the furnace with regard to exhausters or prevailing wind direction. Chlorine is heavier than air. This fact should be kept in mind when determining installation locations of heating equip- ment and building exhaust systems.

STEP 1 - Decide which Venting System to Install:

Type of | Type of Vent System | Vent Configuration/Options | Type of VENT Pipe* Required |

Installation | (Description/Instructions) | Required |

|

|

|

|

|

COMMERCIAL/ | S | Horizontal Vent / Option CC6 | Use either vent pipe approved for a Category III |

INDUS TRIAL | (uses a power venter to duct | (includes concentric adapter box, | appliance OR |

(Harmonized | combustion air from outdoors | exhaust terminal, and inlet air guard) | galvanized (or a material of equivalent durability |

ANS I | and exhaust flue products to | Vertical Vent / Option CC2 | and corrosion resistance) vent pipe. |

and Canadian | the outdoors) - (follow | (includes concentric adapter box, |

|

S tandard | Instructions in S ection 7A) | exhaust terminal, and combustion air |

|

CAN/CGA 2.6- |

| inlet) |

|

M96) |

| Horizontal Vent / Option CC1 | Use either vent pipe approved for a Category III |

| venter to draw combustion air | Vent Cap or | appliance OR appropriately sealed |

| from the indoor space and | equivalent (see page 11) | galvanized steel or equivalent |

| exhaust flue products to the |

| local code requires, the terminal section may be |

| outdoors) - (follow |

| |

| Instructions in S ection 7B) |

|

|

| At least 1/2 of the Equivalent | Vent pipe listed above for a horizontal power- | |

|

| ||

|

| Vent Length is Vertical / Option | vented system may be used, OR vent pipe |

|

| CC1 Vent Cap or | approved for a Category I heater may be used. |

|

| equivalent (see page 11) | |

|

|

| pipe are suitable for use with a Category I heater. |

|

|

| If local code requires, the terminal section may be |

|

|

|

STEP 2 - Follow the instructions that apply to the type of vent being installed

•

Using required pipe (See Table above), FOLLOW INSTRUCTIONS IN SECTION 7A

•Power Vent

Using required pipe (See Table above), FOLLOW INSTRUCTIONS IN SECTION 7B

Form 405, Page 4