| Minimum Clearances for Vent | |

S tructure | Termination Location (all | |

| directions unless specified) | |

|

| |

Forced air inlet within 10 ft | 3 ft (0.9m) above | |

(3.1m) |

|

|

|

|

|

Combustion air inlet of | 6 ft (1.8m) |

|

another app liance |

|

|

|

| |

Door, window, or gravity air | 4 ft (1.2m) horizontally | |

inlet (any building op ening) | 4 ft (1.2m) below | |

|

| |

| 1 ft (30cm) above | |

Electric meter, gas meter * | 4 ft (1.2m) | *Do not terminat e |

and relief equip ment | horizontally | t he vent directly |

|

| above a gas meter |

Gas regulator * | 3 ft (0.9m) | or service regulat or. |

|

|

|

Adjoining building or p arap et | 6 ft (1.8m) |

|

Adjacent p ublic walkway s | 7 ft (2.1m) above | |

Grade (ground level) | 7 ft (2.1m) above | |

|

|

|

2.Prepare clearance hole through the outside wall for a 6" diameter pipe (Size 150 or 200) or an 8" diameter pipe (Size 250, 300, 350, or 400). Outside wall construction thickness should be between 1" (25mm) minimum and 30" (762mm) maximum. The larger diameter combustion air pipe serves as clearance for the exhaust pipe on

3.Prepare the concentric adapter box.

3a) Determine whether

required. The box must be positioned so that the distance from the outside of the wall to the box is a minimum of 12" (305mm). Maximum distance is 60" (1524mm). If brackets are used, box should be angled slightly to allow for downward pitch of pipes. If used, attach brackets securely; do not leave any unsealed holes in the adapter box.

If brackets are not used, when the box is installed, position it tight against the wall.

3b) Install the rubber seal and the vent pipe. Locate the vent pipe opening (no collar) and place the rubber seal around and over the edge of the metal.

Determine the length of the section of vent pipe by adding the requirements. On the heater side of all Sizes except CAUA 250, the vent pipe must extend no more than 6" (152mm) (length limit does not apply to Size 250 because the pipe diameter does not change); plus 6" (152mm) through the box; plus bracket length; plus the width of the wall; plus a minimum of 18" (457mm)

|

|

|

|

|

| on the outside (if | |

| Worksheet - Determine Length of | ||||||

| the inlet air pipe | ||||||

| Vent Pipe through the Box |

|

| ||||

|

|

| extends recom- | ||||

|

|

| inches | m m | |||

|

|

| mended | 2" | |||

| Heater Side (max if | + | 6 | 152 |

| ||

|

| (51mm) beyond | |||||

| diameter changes) |

|

|

|

| ||

|

|

|

|

| the wall). |

| |

| Width of Box | + | 6 | 152 |

|

| |

|

| Lubricate the seal | |||||

| Bracket Length | + | __ | ___ |

| ||

|

| and pipe with liq- | |||||

| Width of Wall | + | __ | ___ |

| ||

|

| uid soap or a rub- | |||||

| Terminal Side (min) | + | 18 | 457 |

| ||

|

| ber lubricant. (In- | |||||

| Length of Pipe | = |

|

|

| ||

|

|

|

| stallation | Tip: | ||

|

|

|

|

|

| Spray cooking oil | |

|

|

|

|

|

| ||

|

|

|

|

|

| ||

| works well as a lubricant for this task.) |

| |||||

Being sure the pipe is in the proper flow direction, slide the end through the box and push it out through the rubber seal. Push evenly using caution not to dis- place the seal from its position on the edge of the hole. If the rubber seal moves, slide the pipe back slightly,

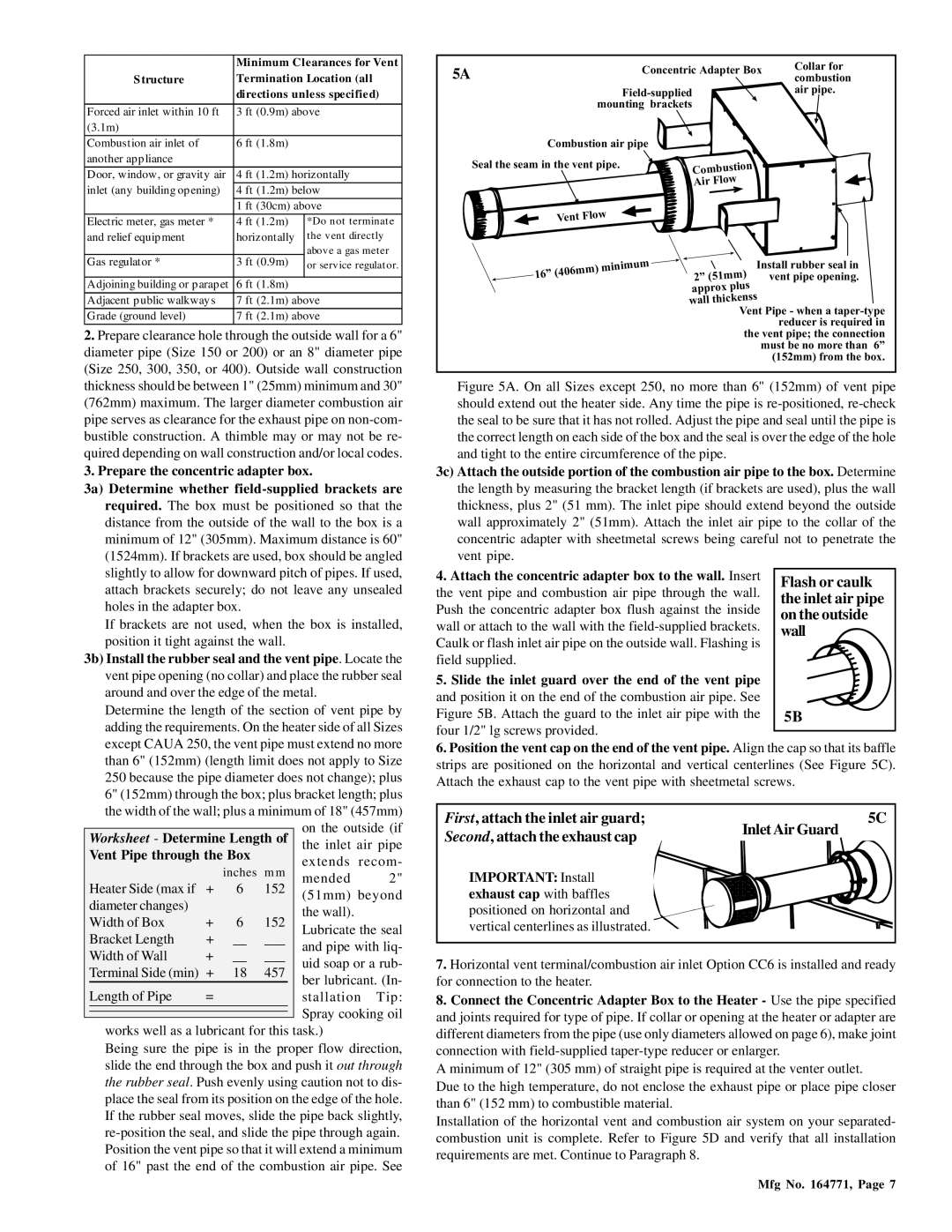

5A |

| Concentric Adapter Box | Collar for | ||

| combustion | ||||

|

|

| air pipe. | ||

| mounting brackets |

|

| ||

Combustion air pipe |

|

|

| ||

Seal the seam in the vent pipe. | Combustion |

|

| ||

|

|

|

|

| |

|

|

| Air Flow |

|

|

| Vent Flow |

|

|

| |

16” | (406mm) | minimum | 2” (51mm) | Install rubber seal in | |

|

| vent pipe opening. | |||

|

|

| approx plus |

|

|

|

|

| wall thickenss |

| |

|

|

| Vent Pipe - when a | ||

|

|

|

|

| reducer is required in |

|

|

| the vent pipe; the connection | ||

|

|

|

| must be no more than 6” | |

|

|

|

|

| (152mm) from the box. |

Figure 5A. On all Sizes except 250, no more than 6" (152mm) of vent pipe should extend out the heater side. Any time the pipe is re-positioned, re-check the seal to be sure that it has not rolled. Adjust the pipe and seal until the pipe is the correct length on each side of the box and the seal is over the edge of the hole and tight to the entire circumference of the pipe.

3c) Attach the outside portion of the combustion air pipe to the box. Determine the length by measuring the bracket length (if brackets are used), plus the wall thickness, plus 2" (51 mm). The inlet pipe should extend beyond the outside wall approximately 2" (51mm). Attach the inlet air pipe to the collar of the concentric adapter with sheetmetal screws being careful not to penetrate the vent pipe.

4. Attach the concentric adapter box to the wall. Insert | Flash or caulk | |

the vent pipe and combustion air pipe through the wall. | ||

the inlet air pipe | ||

Push the concentric adapter box flush against the inside | ||

on the outside | ||

wall or attach to the wall with the | wall | |

Caulk or flash inlet air pipe on the outside wall. Flashing is |

| |

field supplied. |

|

5. Slide the inlet guard over the end of the vent pipe

and position it on the end of the combustion air pipe. See

Figure 5B. Attach the guard to the inlet air pipe with the 5B four 1/2" lg screws provided.

6.Position the vent cap on the end of the vent pipe. Align the cap so that its baffle strips are positioned on the horizontal and vertical centerlines (See Figure 5C). Attach the exhaust cap to the vent pipe with sheetmetal screws.

First, attach the inlet air guard; | 5C |

Second, attach the exhaust cap | Inlet Air Guard |

| |

IMPORTANT: Install |

|

exhaust cap with baffles |

|

positioned on horizontal and |

|

vertical centerlines as illustrated. |

|

7.Horizontal vent terminal/combustion air inlet Option CC6 is installed and ready for connection to the heater.

8.Connect the Concentric Adapter Box to the Heater - Use the pipe specified and joints required for type of pipe. If collar or opening at the heater or adapter are different diameters from the pipe (use only diameters allowed on page 6), make joint connection with

A minimum of 12" (305 mm) of straight pipe is required at the venter outlet.

Due to the high temperature, do not enclose the exhaust pipe or place pipe closer than 6" (152 mm) to combustible material.

Installation of the horizontal vent and combustion air system on your separated- combustion unit is complete. Refer to Figure 5D and verify that all installation requirements are met. Continue to Paragraph 8.

Mfg No. 164771, Page 7