7. Venting and Combustion Air (cont'd)

7A. Venting and Combustion Air Requirements for

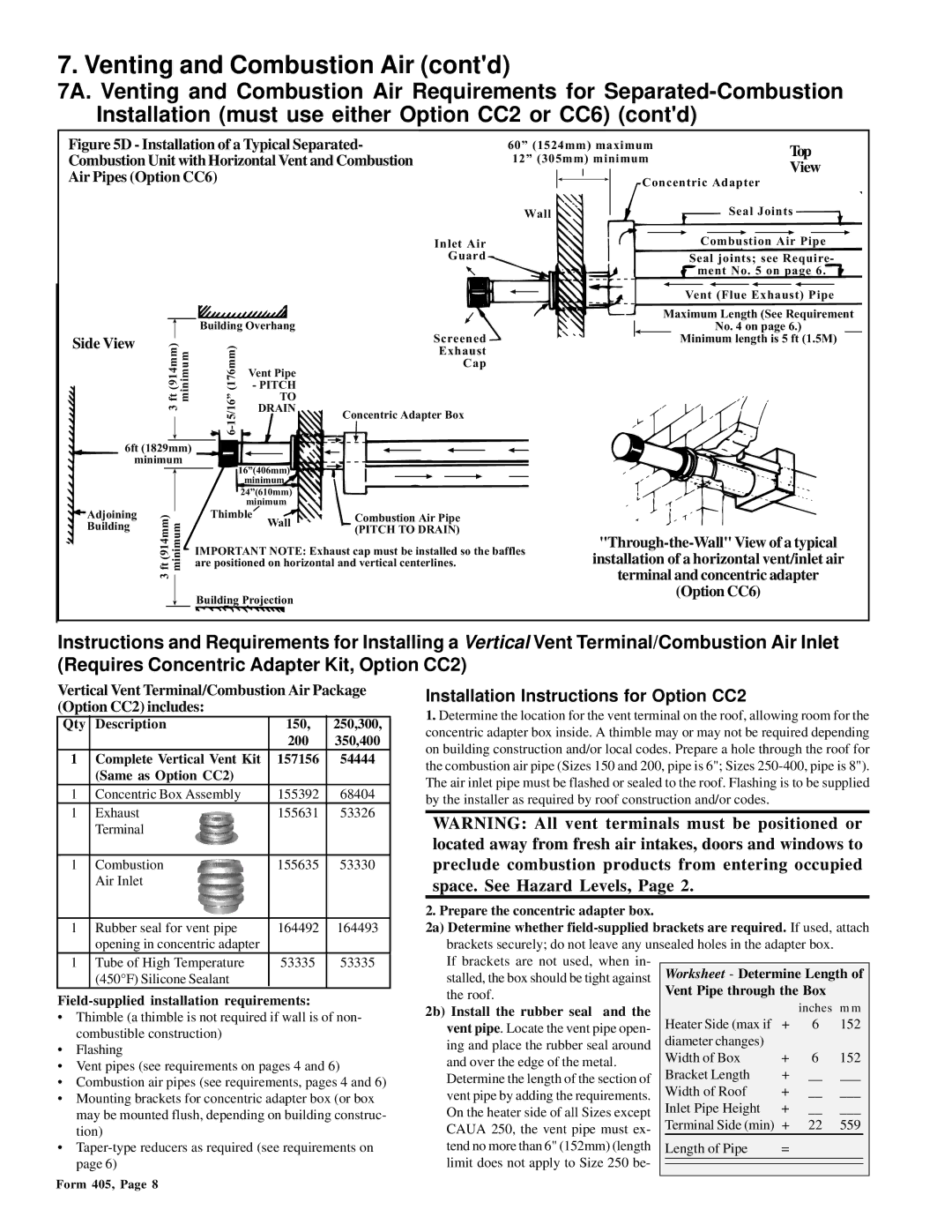

Figure 5D - Installation of a Typical Separated- Combustion Unit with Horizontal Vent and Combustion Air Pipes (Option CC6)

Inlet Air

Guard

60” (1524mm) maximum

12” (305mm) minimumTop

View

| Concentric Adapter |

Wall | Seal Joints |

| Combustion Air Pipe |

| Seal joints; see Require- |

| ment No. 5 on page 6. |

| Vent (Flue Exhaust) Pipe |

| Maximum Length (See Requirement |

Side View

![]() Building Overhang

Building Overhang

(914mm)ft3 minimum | (176mm)15/16” | Vent Pipe |

|

| - PITCH |

|

| TO |

|

| DRAIN |

| 6- |

|

Screened

Exhaust

Cap

Concentric Adapter Box

No. 4 on page 6.) |

Minimum length is 5 ft (1.5M) |

6ft (1829mm)

minimum

Adjoining

Building (914mm)minimum ft3

![]()

![]() 16”(406mm)

16”(406mm) ![]()

![]() minimum

minimum![]()

![]()

24”(610mm)

minimum

Thimble | Wall | Combustion Air Pipe |

| (PITCH TO DRAIN) | |

|

|

IMPORTANT NOTE: Exhaust cap must be installed so the baffles are positioned on horizontal and vertical centerlines.

Building Projection

Instructions and Requirements for Installing a Vertical Vent Terminal/Combustion Air Inlet (Requires Concentric Adapter Kit, Option CC2)

Vertical Vent Terminal/Combustion Air Package (Option CC2) includes:

Qty | Description | 150, | 250,300, |

|

| 200 | 350,400 |

1 | Complete Vertical Vent Kit | 157156 | 54444 |

| (Same as Option CC2) |

|

|

1 | Concentric Box Assembly | 155392 | 68404 |

1 | Exhaust | 155631 | 53326 |

| Terminal |

|

|

|

|

|

|

1 | Combustion | 155635 | 53330 |

| Air Inlet |

|

|

|

|

|

|

1 | Rubber seal for vent pipe | 164492 | 164493 |

| opening in concentric adapter |

|

|

1 | Tube of High Temperature | 53335 | 53335 |

| (450°F) Silicone Sealant |

|

|

Field-supplied installation requirements:

•Thimble (a thimble is not required if wall is of non- combustible construction)

•Flashing

•Vent pipes (see requirements on pages 4 and 6)

•Combustion air pipes (see requirements, pages 4 and 6)

•Mounting brackets for concentric adapter box (or box may be mounted flush, depending on building construc- tion)

•

Installation Instructions for Option CC2

1.Determine the location for the vent terminal on the roof, allowing room for the concentric adapter box inside. A thimble may or may not be required depending on building construction and/or local codes. Prepare a hole through the roof for the combustion air pipe (Sizes 150 and 200, pipe is 6"; Sizes

WARNING: All vent terminals must be positioned or located away from fresh air intakes, doors and windows to preclude combustion products from entering occupied space. See Hazard Levels, Page 2.

2. Prepare the concentric adapter box.

2a) Determine whether

If brackets are not used, when in- stalled, the box should be tight against the roof.

2b) Install the rubber seal and the |

|

| inches | m m | |

vent pipe. Locate the vent pipe open- | Heater Side (max if | + | 6 | 152 | |

ing and place the rubber seal around | diameter changes) |

|

|

| |

Width of Box | + | 6 | 152 | ||

and over the edge of the metal. | |||||

Bracket Length | + | __ | ___ | ||

Determine the length of the section of | |||||

Width of Roof | + | __ | ___ | ||

vent pipe by adding the requirements. | |||||

Inlet Pipe Height | + | __ | ___ | ||

On the heater side of all Sizes except | |||||

Terminal Side (min) | + | 22 | 559 | ||

CAUA 250, the vent pipe must ex- | |||||

tend no more than 6" (152mm) (length | Length of Pipe | = |

|

| |

limit does not apply to Size 250 be- |

|

|

|

| |

|

|

|

| ||

|

|

|

|

Form 405, Page 8