Installation

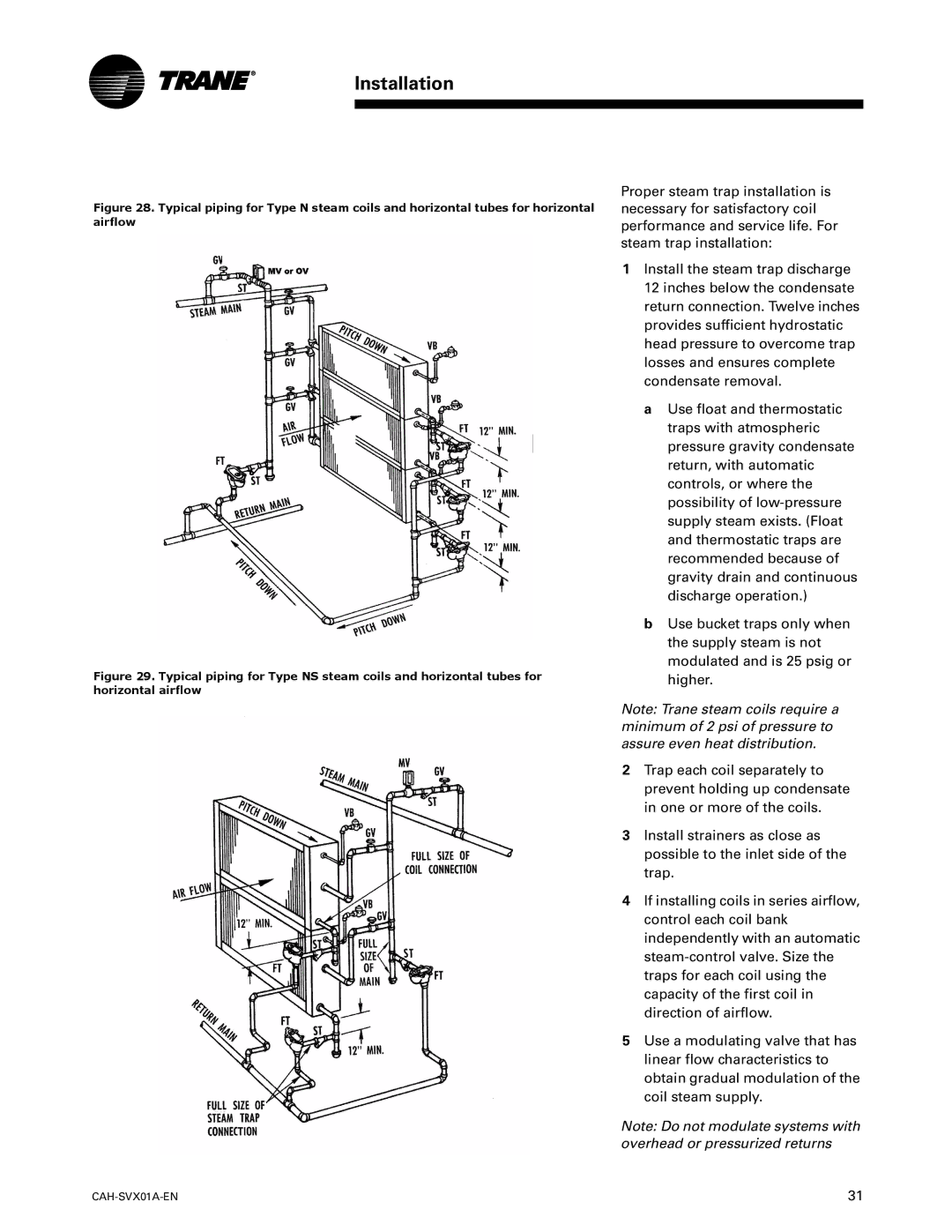

Figure 28. Typical piping for Type N steam coils and horizontal tubes for horizontal airflow

Figure 29. Typical piping for Type NS steam coils and horizontal tubes for horizontal airflow

Proper steam trap installation is necessary for satisfactory coil performance and service life. For steam trap installation:

1Install the steam trap discharge 12 inches below the condensate return connection. Twelve inches provides sufficient hydrostatic head pressure to overcome trap losses and ensures complete condensate removal.

a Use float and thermostatic

traps with atmospheric pressure gravity condensate return, with automatic controls, or where the possibility of

b Use bucket traps only when the supply steam is not modulated and is 25 psig or higher.

Note: Trane steam coils require a minimum of 2 psi of pressure to assure even heat distribution.

2Trap each coil separately to prevent holding up condensate in one or more of the coils.

3Install strainers as close as possible to the inlet side of the trap.

4If installing coils in series airflow, control each coil bank independently with an automatic

5Use a modulating valve that has linear flow characteristics to obtain gradual modulation of the coil steam supply.

Note: Do not modulate systems with overhead or pressurized returns

| 31 |