Installation

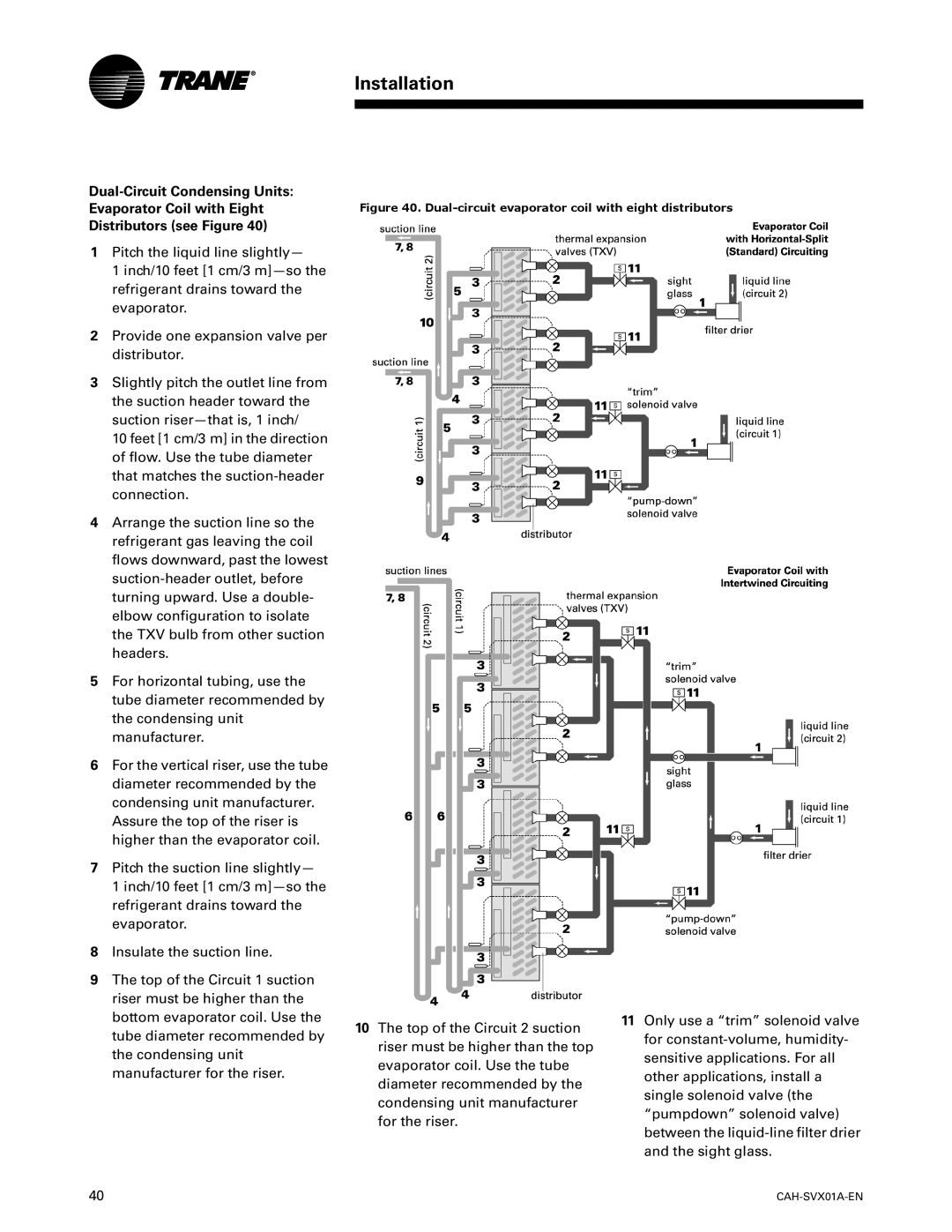

Figure 40. Dual-circuit evaporator coil with eight distributors

1Pitch the liquid line slightly—

1 inch/10 feet [1 cm/3

2Provide one expansion valve per distributor.

3Slightly pitch the outlet line from the suction header toward the suction

10 feet [1 cm/3 m] in the direction of flow. Use the tube diameter that matches the

4Arrange the suction line so the refrigerant gas leaving the coil flows downward, past the lowest

5For horizontal tubing, use the tube diameter recommended by the condensing unit manufacturer.

6For the vertical riser, use the tube diameter recommended by the condensing unit manufacturer. Assure the top of the riser is higher than the evaporator coil.

7Pitch the suction line slightly—

1 inch/10 feet [1 cm/3

8Insulate the suction line.

9The top of the Circuit 1 suction riser must be higher than the bottom evaporator coil. Use the tube diameter recommended by the condensing unit manufacturer for the riser.

10The top of the Circuit 2 suction riser must be higher than the top evaporator coil. Use the tube diameter recommended by the condensing unit manufacturer for the riser.

11Only use a “trim” solenoid valve for

40 |

|