Troubleshooting

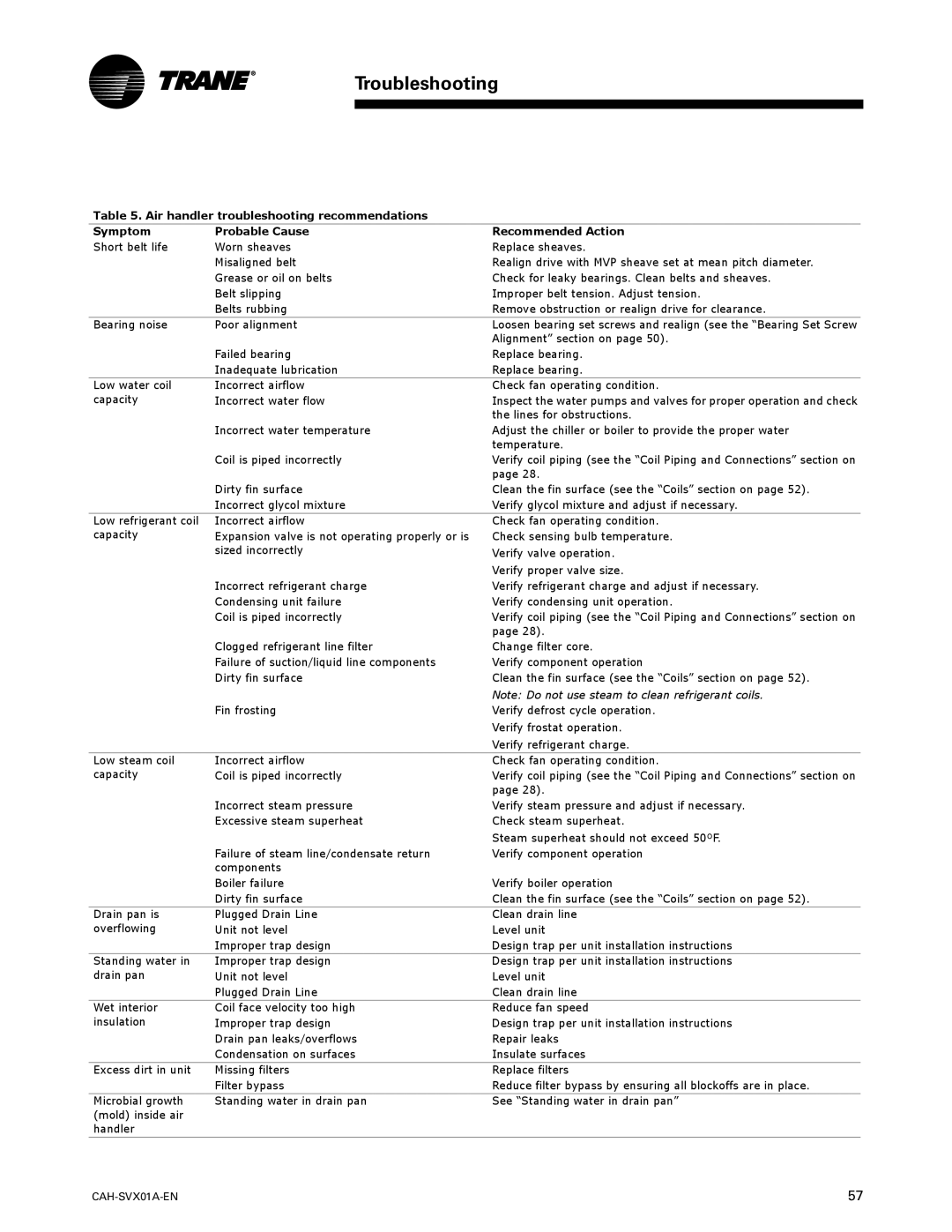

Table 5. Air handler troubleshooting recommendations

Symptom | Probable Cause | Recommended Action |

Short belt life | Worn sheaves | Replace sheaves. |

| Misaligned belt | Realign drive with MVP sheave set at mean pitch diameter. |

| Grease or oil on belts | Check for leaky bearings. Clean belts and sheaves. |

| Belt slipping | Improper belt tension. Adjust tension. |

| Belts rubbing | Remove obstruction or realign drive for clearance. |

|

|

|

Bearing noise | Poor alignment | Loosen bearing set screws and realign (see the “Bearing Set Screw |

|

| Alignment” section on page 50). |

| Failed bearing | Replace bearing. |

| Inadequate lubrication | Replace bearing. |

|

|

|

Low water coil | Incorrect airflow | Check fan operating condition. |

capacity | Incorrect water flow | Inspect the water pumps and valves for proper operation and check |

|

| the lines for obstructions. |

| Incorrect water temperature | Adjust the chiller or boiler to provide the proper water |

|

| temperature. |

| Coil is piped incorrectly | Verify coil piping (see the “Coil Piping and Connections” section on |

|

| page 28. |

| Dirty fin surface | Clean the fin surface (see the “Coils” section on page 52). |

| Incorrect glycol mixture | Verify glycol mixture and adjust if necessary. |

|

|

|

Low refrigerant coil | Incorrect airflow | Check fan operating condition. |

capacity | Expansion valve is not operating properly or is | Check sensing bulb temperature. |

| sized incorrectly | Verify valve operation. |

|

| Verify proper valve size. |

| Incorrect refrigerant charge | Verify refrigerant charge and adjust if necessary. |

| Condensing unit failure | Verify condensing unit operation. |

| Coil is piped incorrectly | Verify coil piping (see the “Coil Piping and Connections” section on |

|

| page 28). |

| Clogged refrigerant line filter | Change filter core. |

| Failure of suction/liquid line components | Verify component operation |

| Dirty fin surface | Clean the fin surface (see the “Coils” section on page 52). |

|

| Note: Do not use steam to clean refrigerant coils. |

| Fin frosting | Verify defrost cycle operation. |

|

| Verify frostat operation. |

|

| Verify refrigerant charge. |

|

|

|

Low steam coil | Incorrect airflow | Check fan operating condition. |

capacity | Coil is piped incorrectly | Verify coil piping (see the “Coil Piping and Connections” section on |

|

| page 28). |

| Incorrect steam pressure | Verify steam pressure and adjust if necessary. |

| Excessive steam superheat | Check steam superheat. |

|

| Steam superheat should not exceed 50ºF. |

| Failure of steam line/condensate return | Verify component operation |

| components |

|

| Boiler failure | Verify boiler operation |

| Dirty fin surface | Clean the fin surface (see the “Coils” section on page 52). |

|

|

|

Drain pan is | Plugged Drain Line | Clean drain line |

overflowing | Unit not level | Level unit |

| Improper trap design | Design trap per unit installation instructions |

|

|

|

Standing water in | Improper trap design | Design trap per unit installation instructions |

drain pan | Unit not level | Level unit |

| Plugged Drain Line | Clean drain line |

|

|

|

Wet interior | Coil face velocity too high | Reduce fan speed |

insulation | Improper trap design | Design trap per unit installation instructions |

| Drain pan leaks/overflows | Repair leaks |

| Condensation on surfaces | Insulate surfaces |

|

|

|

Excess dirt in unit | Missing filters | Replace filters |

| Filter bypass | Reduce filter bypass by ensuring all blockoffs are in place. |

|

|

|

Microbial growth | Standing water in drain pan | See “Standing water in drain pan” |

(mold) inside air handler

| 57 |