Installation

Refrigerant Coil Piping

Note: Refer to the “Protecting the Environment” section on page 3 for information on handling refrigerants.

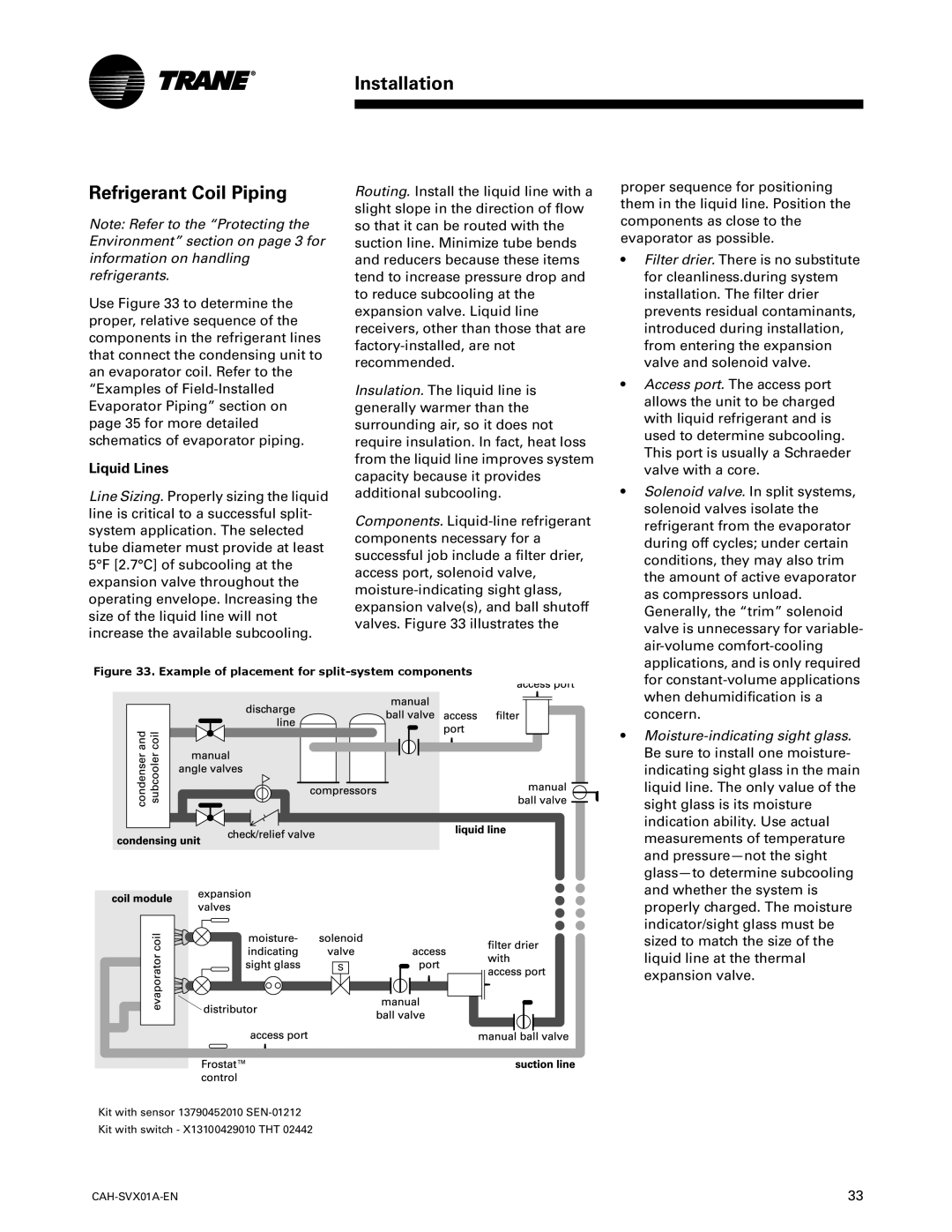

Use Figure 33 to determine the proper, relative sequence of the components in the refrigerant lines that connect the condensing unit to an evaporator coil. Refer to the “Examples of

Liquid Lines

Line Sizing. Properly sizing the liquid line is critical to a successful split- system application. The selected tube diameter must provide at least 5°F [2.7°C] of subcooling at the expansion valve throughout the operating envelope. Increasing the size of the liquid line will not increase the available subcooling.

Routing. Install the liquid line with a slight slope in the direction of flow so that it can be routed with the suction line. Minimize tube bends and reducers because these items tend to increase pressure drop and to reduce subcooling at the expansion valve. Liquid line receivers, other than those that are

Insulation. The liquid line is generally warmer than the surrounding air, so it does not require insulation. In fact, heat loss from the liquid line improves system capacity because it provides additional subcooling.

Components.

proper sequence for positioning them in the liquid line. Position the components as close to the evaporator as possible.

• Filter drier. There is no substitute |

for cleanliness.during system |

installation. The filter drier |

prevents residual contaminants, |

introduced during installation, |

from entering the expansion |

valve and solenoid valve. |

• Access port. The access port |

allows the unit to be charged |

with liquid refrigerant and is |

used to determine subcooling. |

This port is usually a Schraeder |

valve with a core. |

• Solenoid valve. In split systems, |

solenoid valves isolate the |

refrigerant from the evaporator |

during off cycles; under certain |

conditions, they may also trim |

the amount of active evaporator |

as compressors unload. |

Generally, the “trim” solenoid |

valve is unnecessary for variable- |

applications, and is only required |

Figure 33. Example of placement for split-system components

Kit with Kit Kit

Kit with sensor 13790452010

Kit with switch - X13100429010 THT 02442

for |

when dehumidification is a |

concern. |

• |

Be sure to install one moisture- |

indicating sight glass in the main |

liquid line. The only value of the |

sight glass is its moisture |

indication ability. Use actual |

measurements of temperature |

and |

and whether the system is |

properly charged. The moisture |

indicator/sight glass must be |

sized to match the size of the |

liquid line at the thermal |

expansion valve. |

| 33 |