Wall

Thimble

Shield

Wall

Thimble

Face

Plate

Wall Thimble Shield

Seal with RTV Silicone Sealant on Exterior side here (around perimeter)

Wall Thimble

Wall Thimble

Face Plate

ST930

Stardance Direct Vent - Rear Vent Gas Heaters

Vinyl Siding Standoff

Horizontal Termination

ST932

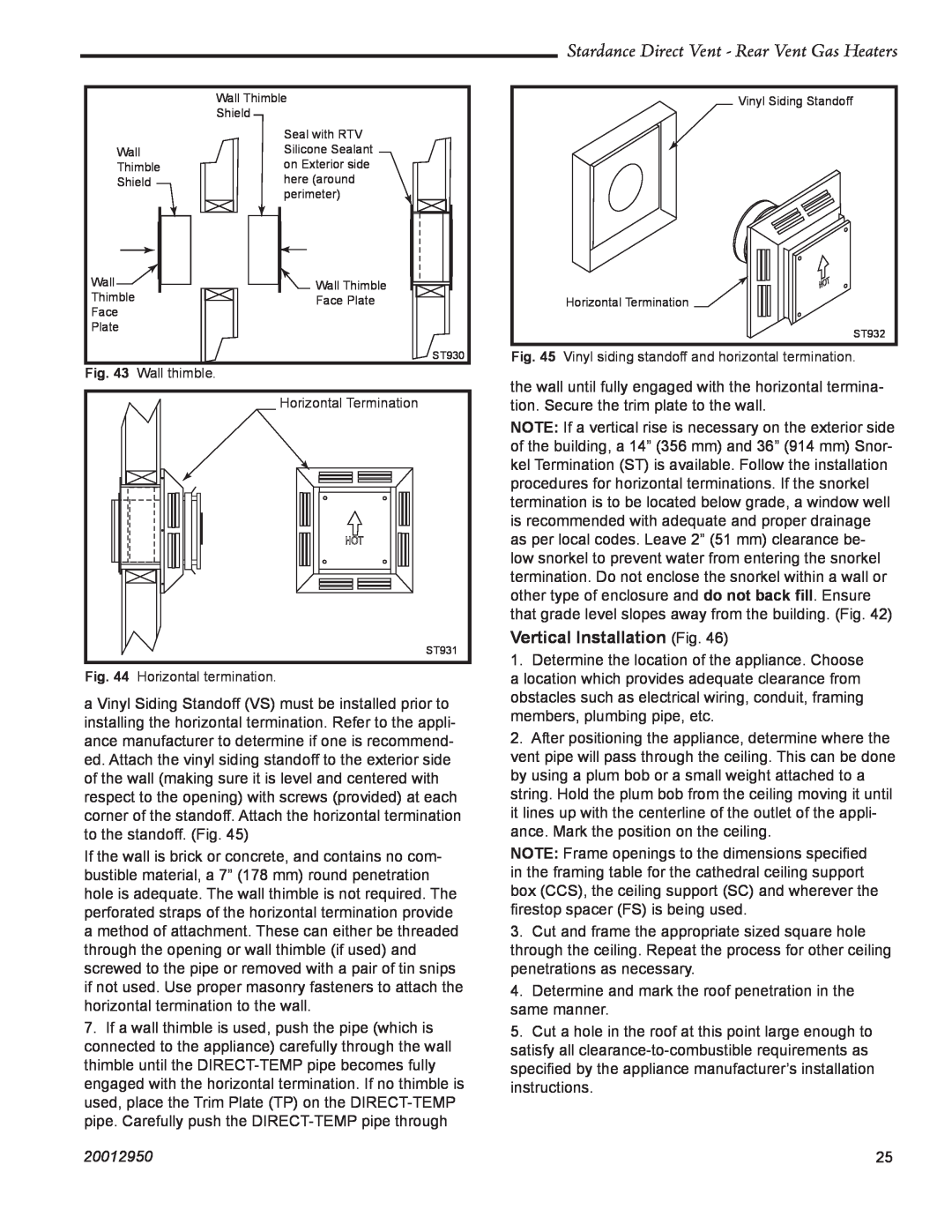

Fig. 45 Vinyl siding standoff and horizontal termination.

Fig. 43 Wall thimble.

Horizontal Termination

ST931

Fig. 44 Horizontal termination.

a Vinyl Siding Standoff (VS) must be installed prior to installing the horizontal termination. Refer to the appli- ance manufacturer to determine if one is recommend- ed. Attach the vinyl siding standoff to the exterior side of the wall (making sure it is level and centered with respect to the opening) with screws (provided) at each corner of the standoff. Attach the horizontal termination to the standoff. (Fig. 45)

If the wall is brick or concrete, and contains no com- bustible material, a 7” (178 mm) round penetration hole is adequate. The wall thimble is not required. The perforated straps of the horizontal termination provide a method of attachment. These can either be threaded through the opening or wall thimble (if used) and screwed to the pipe or removed with a pair of tin snips if not used. Use proper masonry fasteners to attach the horizontal termination to the wall.

7.If a wall thimble is used, push the pipe (which is connected to the appliance) carefully through the wall thimble until the

the wall until fully engaged with the horizontal termina- tion. Secure the trim plate to the wall.

NOTE: If a vertical rise is necessary on the exterior side of the building, a 14” (356 mm) and 36” (914 mm) Snor- kel Termination (ST) is available. Follow the installation procedures for horizontal terminations. If the snorkel termination is to be located below grade, a window well is recommended with adequate and proper drainage as per local codes. Leave 2” (51 mm) clearance be- low snorkel to prevent water from entering the snorkel termination. Do not enclose the snorkel within a wall or other type of enclosure and do not back fill. Ensure that grade level slopes away from the building. (Fig. 42)

Vertical Installation (Fig. 46)

1.Determine the location of the appliance. Choose a location which provides adequate clearance from obstacles such as electrical wiring, conduit, framing members, plumbing pipe, etc.

2.After positioning the appliance, determine where the vent pipe will pass through the ceiling. This can be done by using a plum bob or a small weight attached to a string. Hold the plum bob from the ceiling moving it until it lines up with the centerline of the outlet of the appli- ance. Mark the position on the ceiling.

NOTE: Frame openings to the dimensions specified in the framing table for the cathedral ceiling support box (CCS), the ceiling support (SC) and wherever the firestop spacer (FS) is being used.

3.Cut and frame the appropriate sized square hole through the ceiling. Repeat the process for other ceiling penetrations as necessary.

4.Determine and mark the roof penetration in the same manner.

5.Cut a hole in the roof at this point large enough to satisfy all

20012950 | 25 |