seated. Depress lock tab to secure the cap to the pipe. NOTE: In high wind areas, it is recommended to screw termination to the pipe with two (2) #8 x 1/4” sheet metal screws. The screws should be approximately 3/4” from the bottom of the vertical termination’s galvanized collar.

Connect the Gas Supply Line

Check the rating plate attached by a steel cable to the firebox, to confirm that you have the appropriate firebox for the type of fuel to be used. The Stardance may be converted from one gas to another using the appropri- ate Fuel Conversion Kit listed on Page 47.

CAUTION

This appliance should only be connect- ed by a qualified gas technician. Test to confirm manifold pressures as specified below.

The Stardance Heaters and the individual shut- off valves must be disconnected from the gas supply piping during any pressure testing of that system at test pressures in excess of 1/2 psig (3.5 kPa).

The Stardance Heaters must be isolated from the gas supply piping system by closing the indi- vidual manual shutoff valve during any pressure testing of the gas supply piping system at test pressure equal to or less than 1/2 psig.

There must be a gas shutoff between the stove and the supply.

In order to connect Natural Gas, use a fitting with 3/8” NPT nipple on the valve side and 1/2” natural gas supply line with a minimum input of 21,000 BTUs at a minimum inlet supply for adjustment of 5.5” w.c.

In order to connect Propane, use a fitting with 3/8” NPT nipple on the valve side and 1/2” pro- pane gas supply line with a minimum input of 21,000 BTUs at a and minimum inlet pressure of 11.0” w.c.

In the U.S.: Gas connection should be made in ac- cordance with current National Fuel Gas Code, ANSI Z223.1/NFPA 54. Since some municipalities have additional local codes, be sure to consult your local authority.

In Canada: consult the local authority and

Connect the gas supply and test for leaks. Use a mild soap and water solution applied with a brush no larger than 1” (25 mm). Never apply soap and water solution with a spray bottle. Do not use an open flame for leak testing.

Stardance Direct Vent - Rear Vent Gas Heaters

Burner Information

The appliance must only use the gas specified on the rating plate, unless converted using a Vermont Castings Fuel Conversion Kit. Refer to Page 47 for correct Fuel Conversion Kit for your stove model.

Coversion instructions are provided with each kit and beginning on Page 39 of this manual.

THIS APPLIANCE SHOULD BE CONNECTED TO THE GAS SUPPLY ONLY BY A QUALIFIED GAS SERVICE TECHNICIAN. FOLLOW ALL LOCAL CODES.

THERE MUST BE A GAS SHUT-OFF BETWEEN THE STOVE AND THE SUPPLY.

Complete the Assembly

•Open the swiveling latches (cams) on the top left and right corners of the glass frame.

•Position the glass and frame against the firebox by placing the bottom edge on the brackets on the bot- tom face of the firebox.

•Swing the assembly against the firebox, and close the latches firmly against the pins protruding from the firebox top.

Install ON/OFF Switch

The switch assembly parts are found in the parts bag.

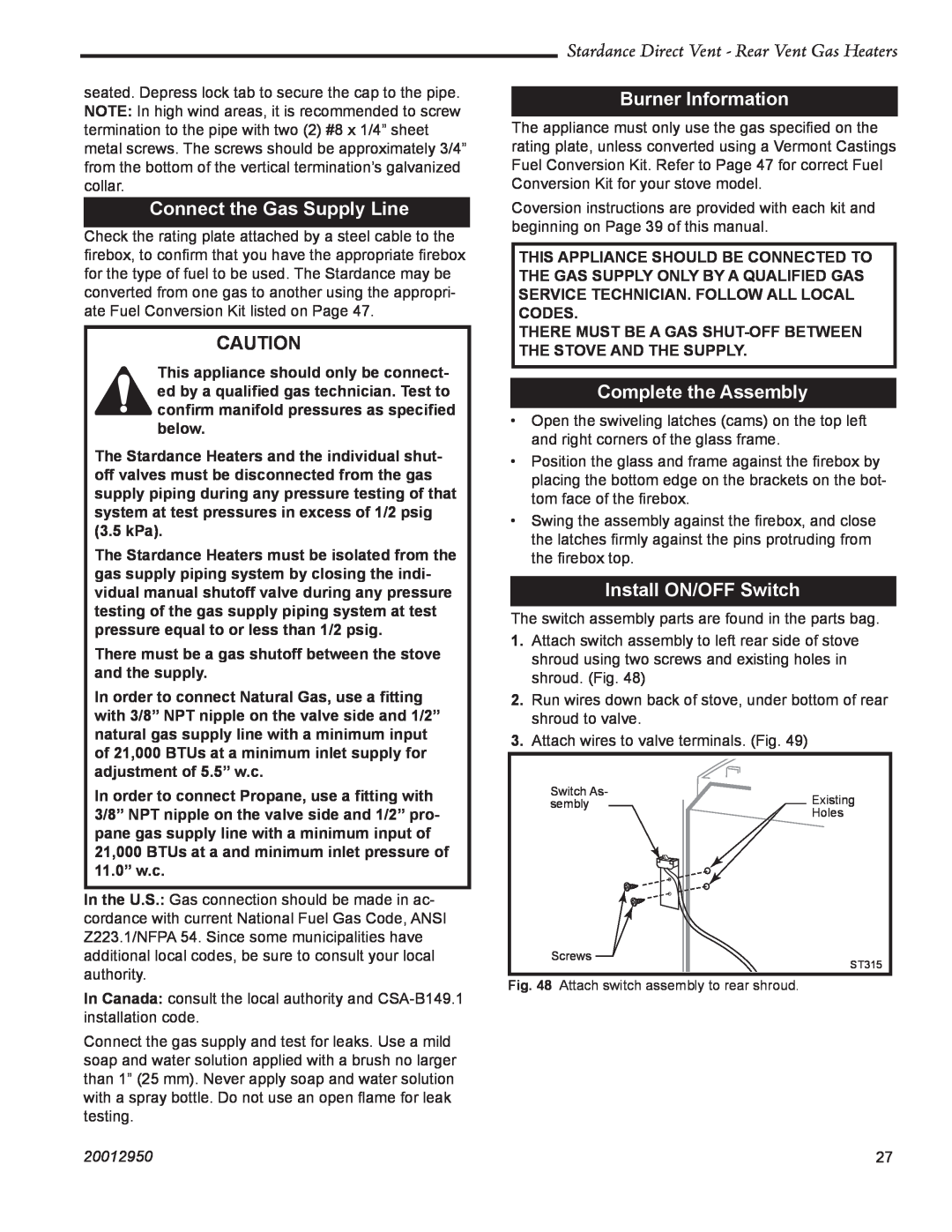

1.Attach switch assembly to left rear side of stove shroud using two screws and existing holes in shroud. (Fig. 48)

2.Run wires down back of stove, under bottom of rear shroud to valve.

3.Attach wires to valve terminals. (Fig. 49)

Switch As- | Existing | |

sembly | ||

Holes | ||

| ||

Screws | ST315 | |

| ||

Fig. 48 Attach switch assembly to rear shroud. |

|

20012950 | 27 |