WHAT TO DO IF YOU SMELL GAS

PLEASE READ THIS MANUAL BEFORE INSTALLING AND USING APPLIANCE

Homeowner’s Installation and Operating Manual

INSTALLER / CONSUMER SAFETY INFORMATION

Stardance Direct Vent - Rear Vent Gas Heaters

20012950

Table of Contents

Stardance Direct Vent / Rear Vent Certified to

Installation & Operating Instructions

ANSI Z21.88-2005 / CSA Z2.33-2005 Vented Gas Fireplace Heaters

Stardance Direct Vent - Rear Vent Gas Heaters

Requirements for the Commonwealth of Massachusetts

Installation of Carbon Monoxide Detectors

MANUFACTURER REQUIREMENTS

Approved Carbon Monoxide Detectors

Fig. 1 Stardance dimensions

Stove Dimensions - Stardance Direct Vent Gas Heater

20012950

229 mm C Valve L Inlet

area to accomplish a safe and effective installation

Installation Requirements

Locating the Stove

Clearance Requirements

Corner Installation Minimum Clearance and Flue Centerline

Parallel Installation Minimum Clearance

Mantel Clearances

and Flue Centerline

Gas Inlet and Manifold Pressures

Gas Specifications

High Elevations

Horizontal Termination

Restrictor Plate Adjustment

Restrictor Plate Adjustment for Extended Pipe Runs

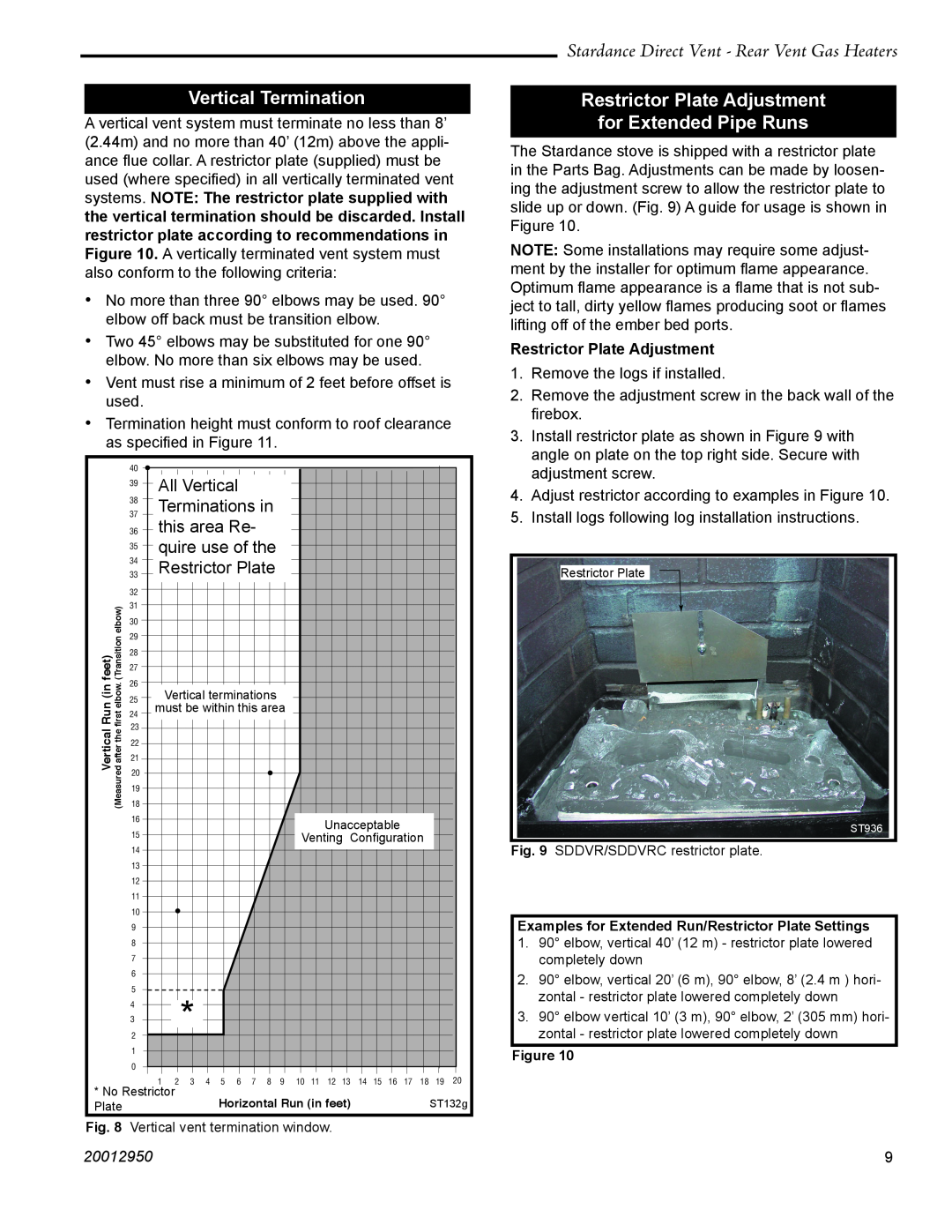

Vertical Termination

All Vertical

Stardance Direct Vent - Rear Vent Gas Heaters

Vent Termination Clearances

Location of Vent Termination

20012950

US Installations2

Canadian Installations1

General Venting Information - Termination Location

Stardance Direct Vent - Rear Vent Gas Heaters

D C C

Termination Clearances

Stardance Direct Vent - Rear Vent Gas Heaters

20012950

12” Non-adjustable Pipe

Below-Grade Installation

12” - 18” Adjustable Pipe

24” Non-adjustable Pipe

Install Optional Fan Kit #2960/FK28

Installation

Fan Kit Contents

Unpack the Stove

Rear Vent

Venting System Assembly General Information

Stardance Direct Vent - Rear Vent Gas Heaters

20012950

Through Side Wall Vent Termination Below Grade

Side Wall Termination Assembly

Stardance Direct Vent - Rear Vent Gas Heaters

1549mm

6. Install the elbow using 3 sheet metal screws at each joint

Stardance Direct Vent - Rear Vent Gas Heaters

20012950

Vent Termination Below Grade

Stardance Direct Vent - Rear Vent Gas Heaters

20012950

Vertical Through Existing Chimney

Vertical Through the Roof Vent Assembly

Fireplace Vent Termination Clearances

9³⁄₈” x 9³⁄₈” 240 x 240mm

Stardance Direct Vent - Rear Vent Gas Heaters

All vegetation within 36” 914 mm that may interfere with the draft

20012950

Fireplace Installations Using Existing Wood Stove Chimneys

Fireplace Installation Requirements

Stardance Direct Vent - Rear Vent Gas Heaters

20012950

Framing Dimension Table

Installation Instructions

Selkirk Direct-Temp Metalbestos Direct Vent System

Appliance Adapter AAV

Offsets

Fig. 39 Selkirk venting components

Stardance Direct Vent - Rear Vent Gas Heaters

20012950

Adjustable Length AJ

Horizontal Installation

Supporting DIRECT-TEMP Horizontal Support

Fire Stopping

Vertical Installation Fig

Stardance Direct Vent - Rear Vent Gas Heaters

20012950

Stardance Direct Vent - Rear Vent Gas Heaters

screws through the support collar and the outer wall of the pipe

20012950

Install ON/OFF Switch

Complete the Assembly

Connect the Gas Supply Line

Burner Information

This completes assembly of the Stardance Rear Vent stove

Install the Front Plate

Thermostat Connection

Use only a thermostat rated for 500 - 750 millivolts

AGED LOGS

Install the Log Set

Stardance Direct Vent - Rear Vent Gas Heaters

20012950

20012950

Stardance Direct Vent - Rear Vent Gas Heaters

LG494

Top Log

CAUTION DO NOT TOUCH DOORS WHEN HOT

Flame & Temperature Adjustment

Operation

Your First Fire

Stardance Direct Vent - Rear Vent Gas Heaters

Flame Characteristics

20012950

Fig. 58 Correct pilot and burner flame patterns

may result causing property damage, personal injury or loss of life

FOR YOUR SAFETY READ BEFORE LIGHTING

Lighting And Operating Instructions

To Turn Off Gas To Heater

Symptom

Troubleshooting the Gas Control System SDDVT Series

SIT NOVA 820 MILLIVOLT VALVE

Possible Causes

Delay Timer Mode

Shut Off Procedure

Instructions for RF Comfort Control Valve

Operation

Disable Thermostat Function

Change Between F/C Temperature Units

Troubleshooting

Service Action

Stardance Direct Vent - Rear Vent Gas Heaters

Comfort Valve System Control Sequence Of Operation With Transmitter

20012950

Local Path

Auto Path

Stardance Direct Vent - Rear Vent Gas Heaters

20012950

Conversion Procedure

Conversion Precautions

Fuel Conversion Instructions

Valve Conversion SDDVR Series Models

Pilot Type

Pilot Orifice Conversion

Pilot type

Stardance Direct Vent - Rear Vent Gas Heaters

All Models

Burner Orifice Conversion

Stardance Direct Vent - Rear Vent Gas Heaters

20012950

Conversion to LP

Table 2. Injector Orifice Size Matrix

Input BTU/h

Conversion to Natural Gas

Logset and Burner Cleaning and Inspection

Maintenance

Cleaning the Glass

Glass Replacement

Stove Disassembly

Gasket Replacement

Inspect the Vent System Annually

Check the Gas Flame Regularly

Fig. 82 On/off switch and optional thermostat circuit

Wiring Diagrams

POWER

Stardance Direct Vent - Rear Vent Gas Heaters

Models SDDVR Series SDDVRCB, SDDVREB, SDDVRMB, SDDVRBS, SDDVRCH

Stardance Direct Vent/Rear Vent Gas Heater

SDDVRVG, SDDVRBD

SDDVRC Series SDDVRCCB, SDDVRCEB, SDDVRCMB, SDDVRCBS, SDDVRCCH

Description

Stardance Direct Vent/Rear Vent Gas Heater continued

SDDVR/SDDVRC

Stardance Direct Vent - Rear Vent Gas Heaters

Stardance Direct Vent/Rear Vent Gas Heater continued

Fuel Conversion Kits

Stardance Direct Vent - Rear Vent Gas Heaters

Description

Remote Controls

Optional Accessories

Maintenance

Installation

20012950

Stardance Direct Vent - Rear Vent Gas Heaters

LIMITED LIFETIME WARRANTY

PRODUCT COVERED BY THIS WARRANTY

20012950

EnerGuide Ratings

Efficiency Ratings

Fireplace Efficiency %

CFM Corporation