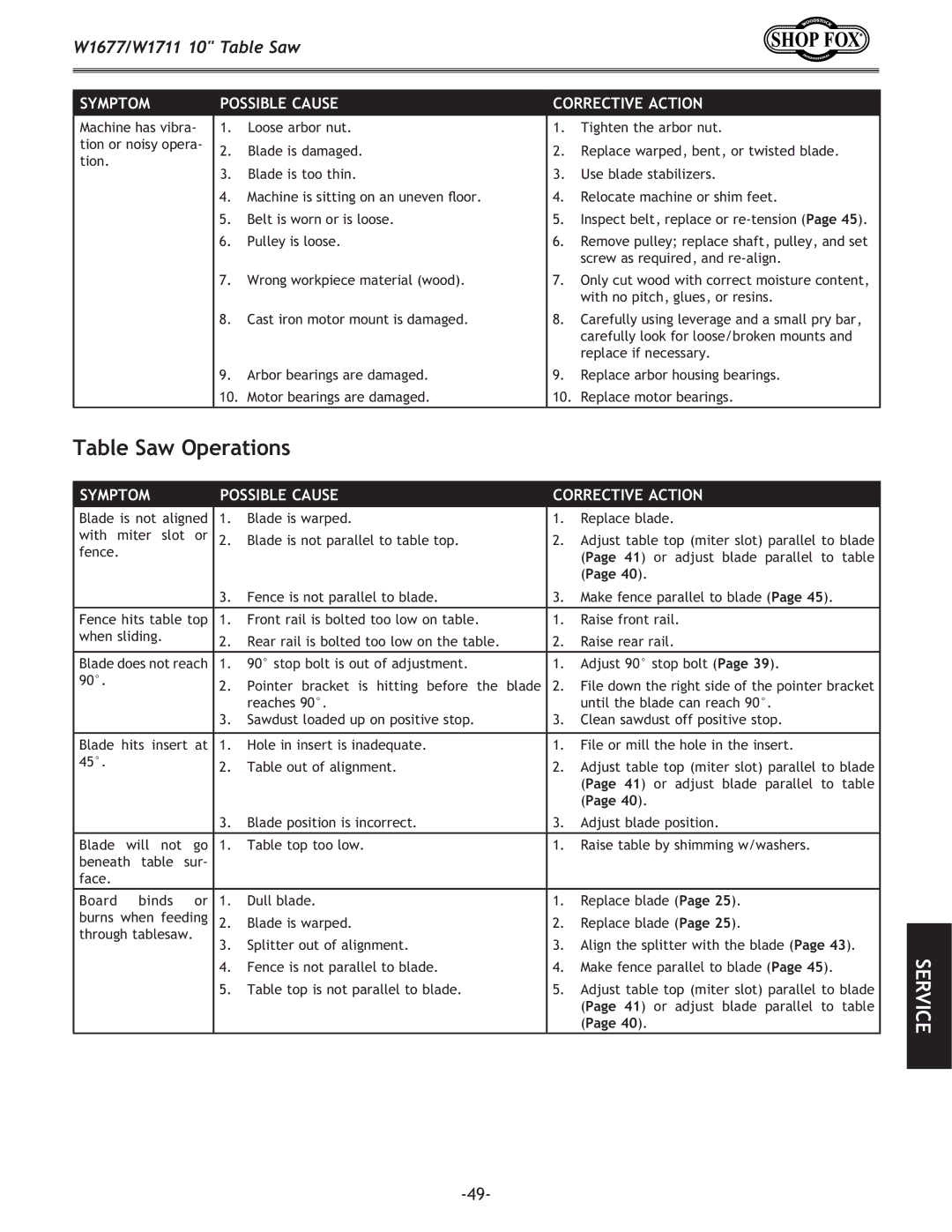

W1677/W1711 10" Table Saw

SYMPTOM | POSSIBLE CAUSE | CORRECTIVE ACTION | |||

Machine has vibra- | 1. Loose arbor nut. | 1. | Tighten the arbor nut. | ||

tion or noisy opera- | 2. Blade is damaged. | 2. | Replace warped, bent, or twisted blade. | ||

tion. | |||||

3. Blade is too thin. | 3. | Use blade stabilizers. | |||

| |||||

| 4. | Machine is sitting on an uneven floor. | 4. | Relocate machine or shim feet. | |

| 5. | Belt is worn or is loose. | 5. | Inspect belt, replace or | |

| 6. | Pulley is loose. | 6. | Remove pulley; replace shaft, pulley, and set | |

|

|

|

| screw as required, and | |

7.Wrong workpiece material (wood).7. Only cut wood with correct moisture content, with no pitch, glues, or resins.

|

|

|

| 8. | Cast iron motor mount is damaged. | 8. | Carefully using leverage and a small pry bar, | ||

|

|

|

|

|

|

| carefully look for loose/broken mounts and | ||

|

|

|

|

|

|

| replace if necessary. |

|

|

|

|

|

| 9. | Arbor bearings are damaged. | 9. | Replace arbor housing bearings. |

|

|

|

|

|

| 10. | Motor bearings are damaged. | 10. | Replace motor bearings. |

|

|

Table Saw Operations |

|

|

|

| |||||

|

|

|

|

|

|

| |||

SYMPTOM |

|

| POSSIBLE CAUSE | CORRECTIVE ACTION |

|

| |||

Blade is not aligned | 1. | Blade is warped. | 1. | Replace blade. |

|

| |||

with | miter | slot | or | 2. | Blade is not parallel to table top. | 2. | Adjust table top (miter slot) parallel to blade | ||

fence. |

|

|

|

|

| (Page 41) or adjust blade parallel | to | table | |

|

|

|

|

|

|

| |||

|

|

|

|

|

|

| (Page 40). |

|

|

|

|

|

| 3. | Fence is not parallel to blade. | 3. | Make fence parallel to blade (Page 45). |

| |

Fence hits table top | 1. | Front rail is bolted too low on table. | 1. | Raise front rail. |

|

| |||

when sliding. |

| 2. | Rear rail is bolted too low on the table. | 2. | Raise rear rail. |

|

| ||

|

|

|

|

|

| ||||

Blade does not reach | 1. | 90° stop bolt is out of adjustment. | 1. | Adjust 90° stop bolt (Page 39). |

|

| |||

90°. |

|

|

| 2. | Pointer bracket is hitting before the blade | 2. | File down the right side of the pointer bracket | ||

|

|

|

| ||||||

|

|

|

|

| reaches 90°. |

| until the blade can reach 90°. |

|

|

|

|

|

| 3. | Sawdust loaded up on positive stop. | 3. | Clean sawdust off positive stop. |

|

|

|

|

|

|

|

|

|

|

|

|

Blade | hits | insert | at | 1. | Hole in insert is inadequate. | 1. | File or mill the hole in the insert. |

|

|

45°. |

|

|

| 2. | Table out of alignment. | 2. | Adjust table top (miter slot) parallel to blade | ||

|

|

|

| ||||||

|

|

|

|

|

|

| (Page 41) or adjust blade parallel | to | table |

|

|

|

|

|

|

| (Page 40). |

|

|

|

|

|

| 3. | Blade position is incorrect. | 3. | Adjust blade position. |

|

|

Blade | will | not | go | 1. | Table top too low. | 1. | Raise table by shimming w/washers. |

|

|

beneath table sur- |

|

|

|

|

|

| |||

face. |

|

|

|

|

|

|

|

|

|

Board | binds | or | 1. | Dull blade. | 1. | Replace blade (Page 25). |

|

| |

burns when feeding | 2. | Blade is warped. | 2. | Replace blade (Page 25). |

|

| |||

through tablesaw. |

| 3. | Splitter out of alignment. | 3. | Align the splitter with the blade (Page 43). | ||||

|

|

|

| ||||||

|

|

|

| 4. | Fence is not parallel to blade. | 4. | Make fence parallel to blade (Page 45). |

| |

|

|

|

| 5. | Table top is not parallel to blade. | 5. | Adjust table top (miter slot) parallel to blade | ||

|

|

|

|

|

|

| (Page 41) or adjust blade parallel | to | table |

|

|

|

|

|

|

| (Page 40). |

|

|

SERVICE