W1677/W1711 10" Table Saw

Resawing Operations

Resawing pushes a table saw to its limits. If the motor bogs down when resawing, slow down your feed rate. Also, use a ripping blade when resawing to reduce motor overloading and blade wear. Ripping blades are designed to clear the sawdust quickly.

Components Needed for Resawing: |

|

Zero Clearance Insert | 1 |

Ripping Blade 10" | 1 |

Clamps | 2 |

Shop Made Auxiliary Fence | 1 |

Shop Made Resaw Barrier | 1 |

To perform resawing operations, do these steps: |

|

1.DISCONNECT THE SAW FROM POWER!

2.Remove the table insert and the blade guard/split- ter, install a ripping blade and a zero clearance table insert, and lower the blade below the table surface.

3.Attach the auxiliary fence to the standard fence and set it to the desired width. Note: Account for blade kerf, the rough cut made by the blade, and the inaccuracy of the fence scale when the auxil- iary fence is installed when figuring out the correct width.

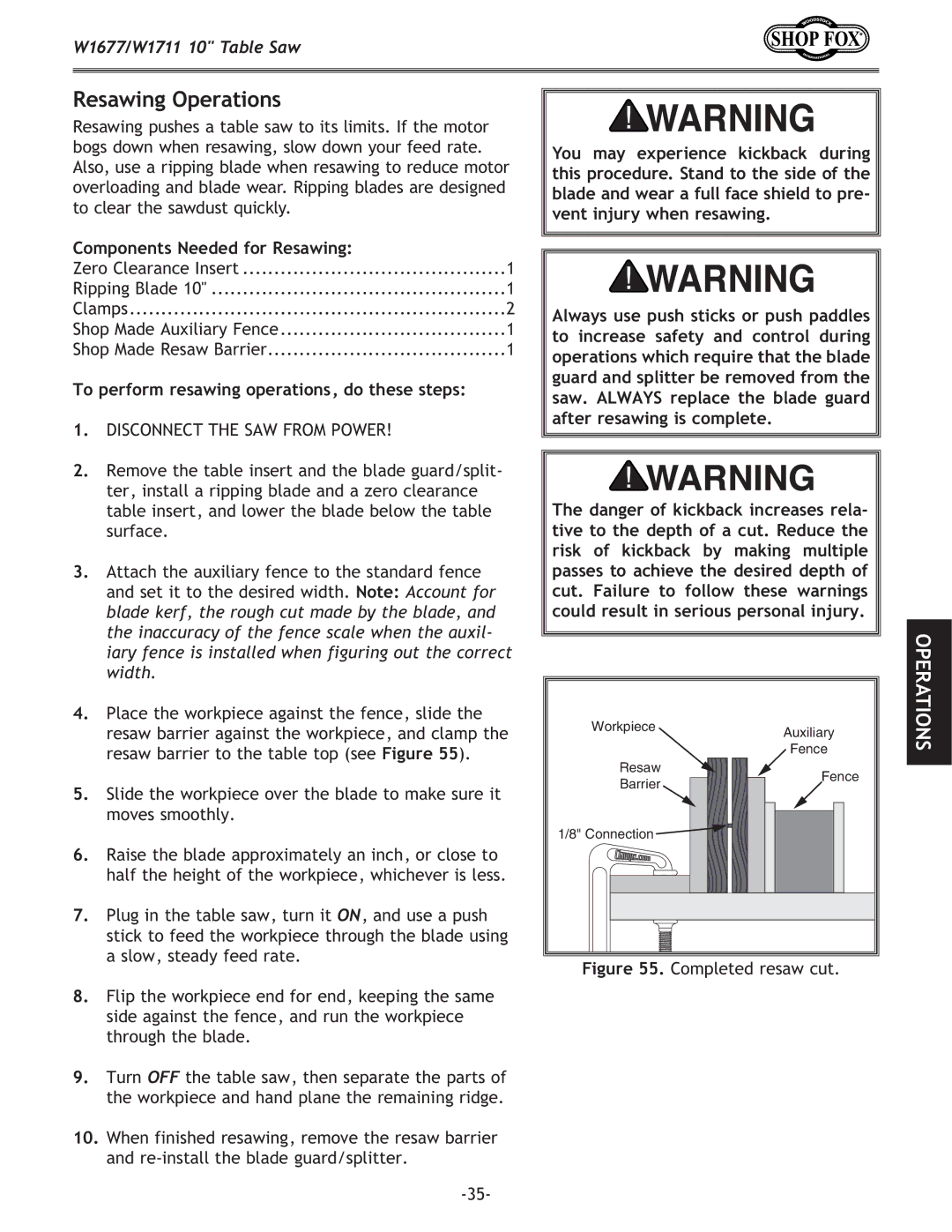

4.Place the workpiece against the fence, slide the resaw barrier against the workpiece, and clamp the resaw barrier to the table top (see Figure 55).

5.Slide the workpiece over the blade to make sure it moves smoothly.

6.Raise the blade approximately an inch, or close to half the height of the workpiece, whichever is less.

7.Plug in the table saw, turn it ON, and use a push stick to feed the workpiece through the blade using a slow, steady feed rate.

8.Flip the workpiece end for end, keeping the same side against the fence, and run the workpiece through the blade.

9.Turn OFF the table saw, then separate the parts of the workpiece and hand plane the remaining ridge.

10.When finished resawing, remove the resaw barrier and

You may experience kickback during this procedure. Stand to the side of the blade and wear a full face shield to pre- vent injury when resawing.

Always use push sticks or push paddles to increase safety and control during operations which require that the blade guard and splitter be removed from the saw. ALWAYS replace the blade guard after resawing is complete.

The danger of kickback increases rela- tive to the depth of a cut. Reduce the risk of kickback by making multiple passes to achieve the desired depth of cut. Failure to follow these warnings could result in serious personal injury.

��������� | ��������� |

| |

| ����� |

�����

������������

��������������� ![]()

Figure 55. Completed resaw cut.

OPERATIONS