W1677/W1711 10" Table Saw

Rip Cuts

Rip cuts or "Ripping" means cutting with the grain of the workpiece. In other materials such as MDF or plywood, ripping simply means cutting lengthwise.

To make a rip cut, do these steps:

1.Review Preventing Kickback on Page 11 and take the necessary precautions to prevent kickback.

2.Joint one long edge of the workpiece on a jointer.

3.DISCONNECT THE SAW FROM POWER!

4.Use the scale to set the fence to the desired width of cut.

5.Adjust the blade height so the teeth protrude approximately 1⁄4" above the workpiece.

6.Set up safety devices such as featherboards or other

7.Rotate the blade to make sure it does not come into contact with any of the safety devices.

8.Plug the saw into the power source, turn it ON, and allow it to reach full speed.

9.The jointed edge of the workpiece must slide against the fence during the cutting operation.

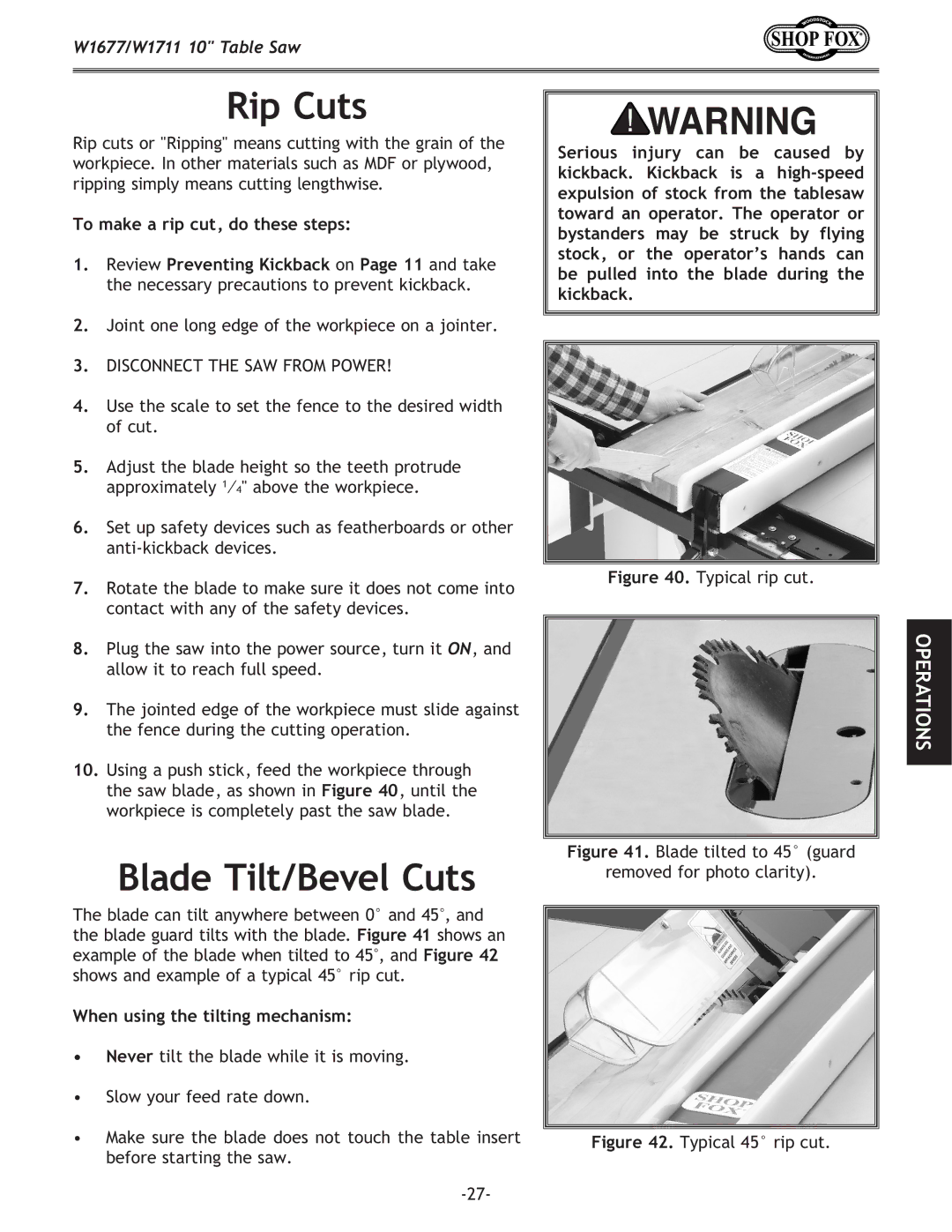

10.Using a push stick, feed the workpiece through the saw blade, as shown in Figure 40, until the workpiece is completely past the saw blade.

Blade Tilt/Bevel Cuts

The blade can tilt anywhere between 0° and 45°, and the blade guard tilts with the blade. Figure 41 shows an example of the blade when tilted to 45°, and Figure 42 shows and example of a typical 45° rip cut.

When using the tilting mechanism:

•Never tilt the blade while it is moving.

•Slow your feed rate down.

•Make sure the blade does not touch the table insert before starting the saw.

Serious injury can be caused by kickback. Kickback is a

Figure 40. Typical rip cut.

Figure 41. Blade tilted to 45° (guard

removed for photo clarity).

Figure 42. Typical 45° rip cut.

OPERATIONS