W1677/W1711 10" Table Saw

17. Raise the blade up to full height, and use a straight- edge to align the blade with the blade splitter, as shown in Figure 29.

18.At the front mounting location on the splitter, use the provided washers (or get thinner electrical wash- ers) to shim between the splitter and the casting

to take up any space, and tighten all the splitter mounting bolts.

Figure 29. Aligning splitter to blade.

19. Loosen the set screws on the lower bracket half (see Figure 28), square the splitter to the table (Figure 30), and retighten the set screws.

Figure 30. Squaring splitter.

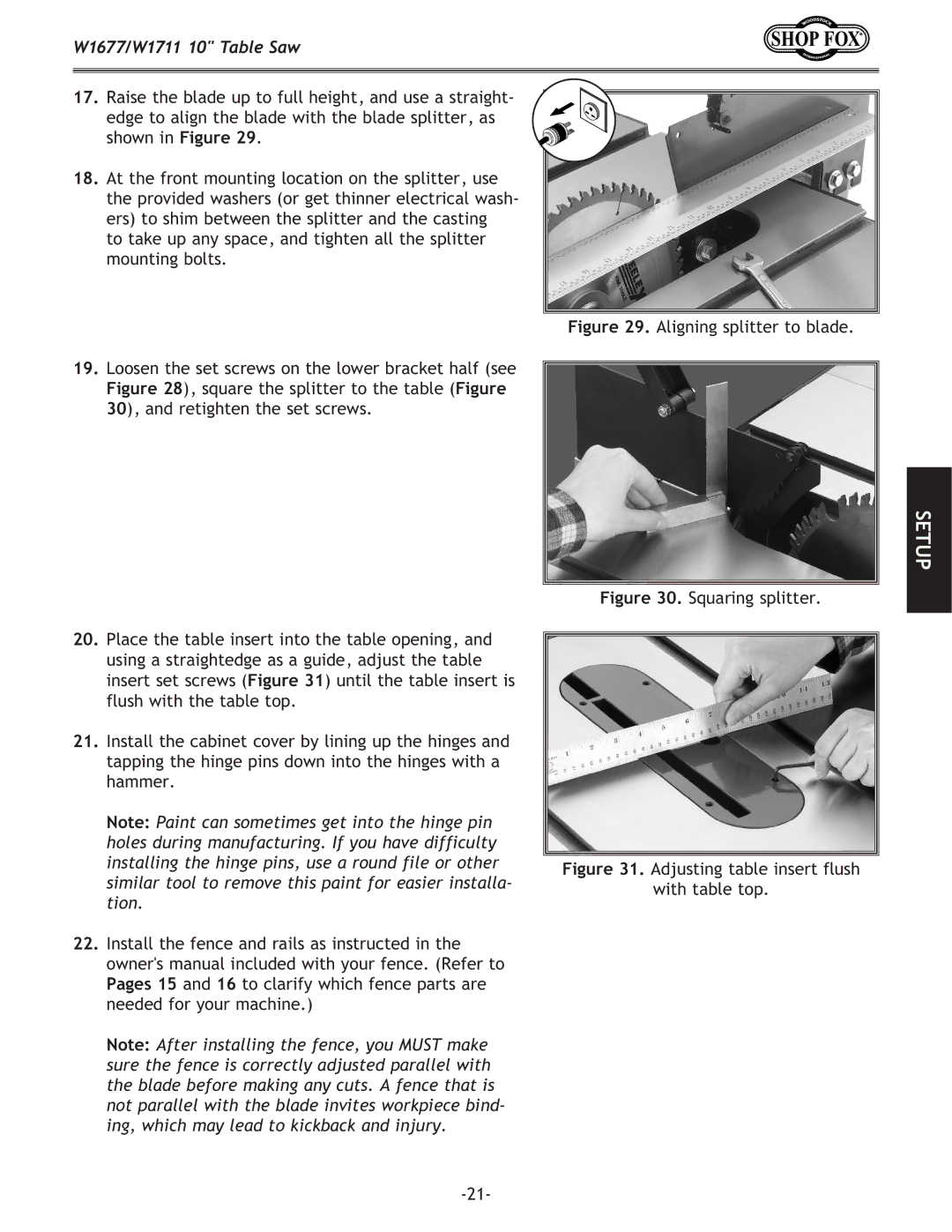

20. Place the table insert into the table opening, and |

| |

| ||

using a straightedge as a guide, adjust the table |

| |

insert set screws (Figure 31) until the table insert is |

| |

flush with the table top. |

| |

21. Install the cabinet cover by lining up the hinges and |

| |

tapping the hinge pins down into the hinges with a |

| |

hammer. |

| |

Note: Paint can sometimes get into the hinge pin |

| |

holes during manufacturing. If you have difficulty |

| |

installing the hinge pins, use a round file or other |

| |

Figure 31. Adjusting table insert flush | ||

similar tool to remove this paint for easier installa- | ||

with table top. | ||

tion. | ||

| ||

22. Install the fence and rails as instructed in the |

| |

owner's manual included with your fence. (Refer to |

| |

Pages 15 and 16 to clarify which fence parts are |

| |

needed for your machine.) |

| |

Note: After installing the fence, you MUST make |

| |

sure the fence is correctly adjusted parallel with |

| |

the blade before making any cuts. A fence that is |

| |

not parallel with the blade invites workpiece bind- |

| |

ing, which may lead to kickback and injury. |

| |

|

SETUP