SERVICE

W1677/W1711 10" Table Saw

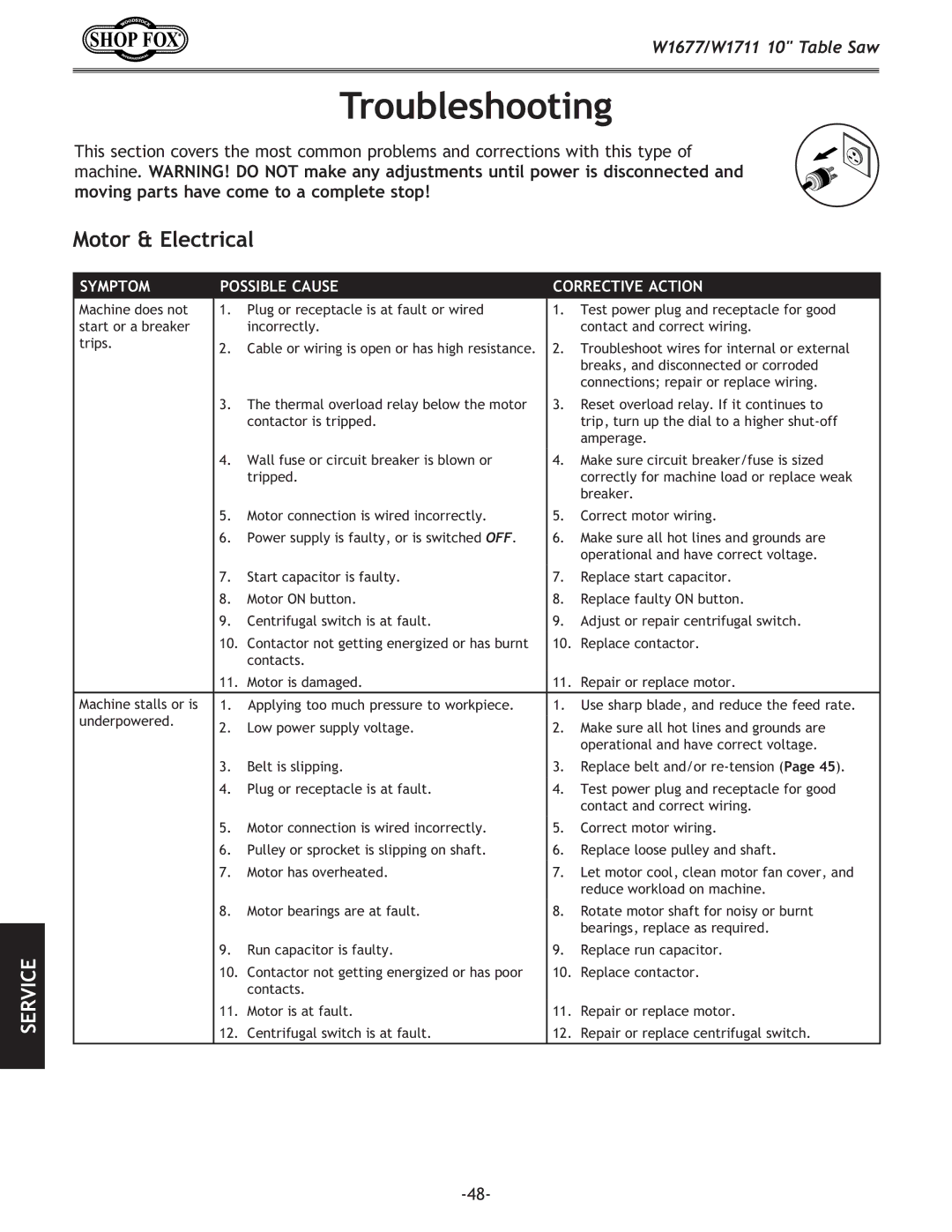

Troubleshooting

This section covers the most common problems and corrections with this type of machine. WARNING! DO NOT make any adjustments until power is disconnected and moving parts have come to a complete stop!

Motor & Electrical

SYMPTOM | POSSIBLE CAUSE | CORRECTIVE ACTION | ||

Machine does not | 1. | Plug or receptacle is at fault or wired | 1. | Test power plug and receptacle for good |

start or a breaker |

| incorrectly. |

| contact and correct wiring. |

trips. | 2. | Cable or wiring is open or has high resistance. | 2. | Troubleshoot wires for internal or external |

| ||||

|

|

|

| breaks, and disconnected or corroded |

|

|

|

| connections; repair or replace wiring. |

| 3. | The thermal overload relay below the motor | 3. | Reset overload relay. If it continues to |

|

| contactor is tripped. |

| trip, turn up the dial to a higher |

|

|

|

| amperage. |

| 4. | Wall fuse or circuit breaker is blown or | 4. | Make sure circuit breaker/fuse is sized |

|

| tripped. |

| correctly for machine load or replace weak |

|

|

|

| breaker. |

| 5. | Motor connection is wired incorrectly. | 5. | Correct motor wiring. |

| 6. | Power supply is faulty, or is switched OFF. | 6. | Make sure all hot lines and grounds are |

|

|

|

| operational and have correct voltage. |

| 7. | Start capacitor is faulty. | 7. | Replace start capacitor. |

| 8. | Motor ON button. | 8. | Replace faulty ON button. |

| 9. | Centrifugal switch is at fault. | 9. | Adjust or repair centrifugal switch. |

| 10. | Contactor not getting energized or has burnt | 10. | Replace contactor. |

|

| contacts. |

|

|

| 11. | Motor is damaged. | 11. | Repair or replace motor. |

Machine stalls or is | 1. | Applying too much pressure to workpiece. | 1. | Use sharp blade, and reduce the feed rate. |

underpowered. | 2. | Low power supply voltage. | 2. | Make sure all hot lines and grounds are |

| ||||

|

|

|

| operational and have correct voltage. |

| 3. | Belt is slipping. | 3. | Replace belt and/or |

| 4. | Plug or receptacle is at fault. | 4. | Test power plug and receptacle for good |

|

|

|

| contact and correct wiring. |

| 5. | Motor connection is wired incorrectly. | 5. | Correct motor wiring. |

| 6. | Pulley or sprocket is slipping on shaft. | 6. | Replace loose pulley and shaft. |

| 7. | Motor has overheated. | 7. | Let motor cool, clean motor fan cover, and |

|

|

|

| reduce workload on machine. |

| 8. | Motor bearings are at fault. | 8. | Rotate motor shaft for noisy or burnt |

|

|

|

| bearings, replace as required. |

| 9. | Run capacitor is faulty. | 9. | Replace run capacitor. |

| 10. | Contactor not getting energized or has poor | 10. | Replace contactor. |

|

| contacts. |

|

|

| 11. | Motor is at fault. | 11. | Repair or replace motor. |

| 12. | Centrifugal switch is at fault. | 12. | Repair or replace centrifugal switch. |