W1677/W1711 10" Table Saw

OPERATIONS

General

Table saws will perform many types of operations that are beyond the scope of this manual. Many of these opera- tions can be dangerous or deadly if performed incorrectly.

The instructions in this section are written with the understanding that the operator has the necessary knowl- edge and skills to operate this machine. If at any time you experience difficulty performing an operation, stop using the machine!

If you are an inexperienced operator, we strongly recom- mend that you read books, trade articles, or seek training from an experienced table saw operator before perform- ing any unfamiliar operations. Above all, your safety should come first!

Blade Height

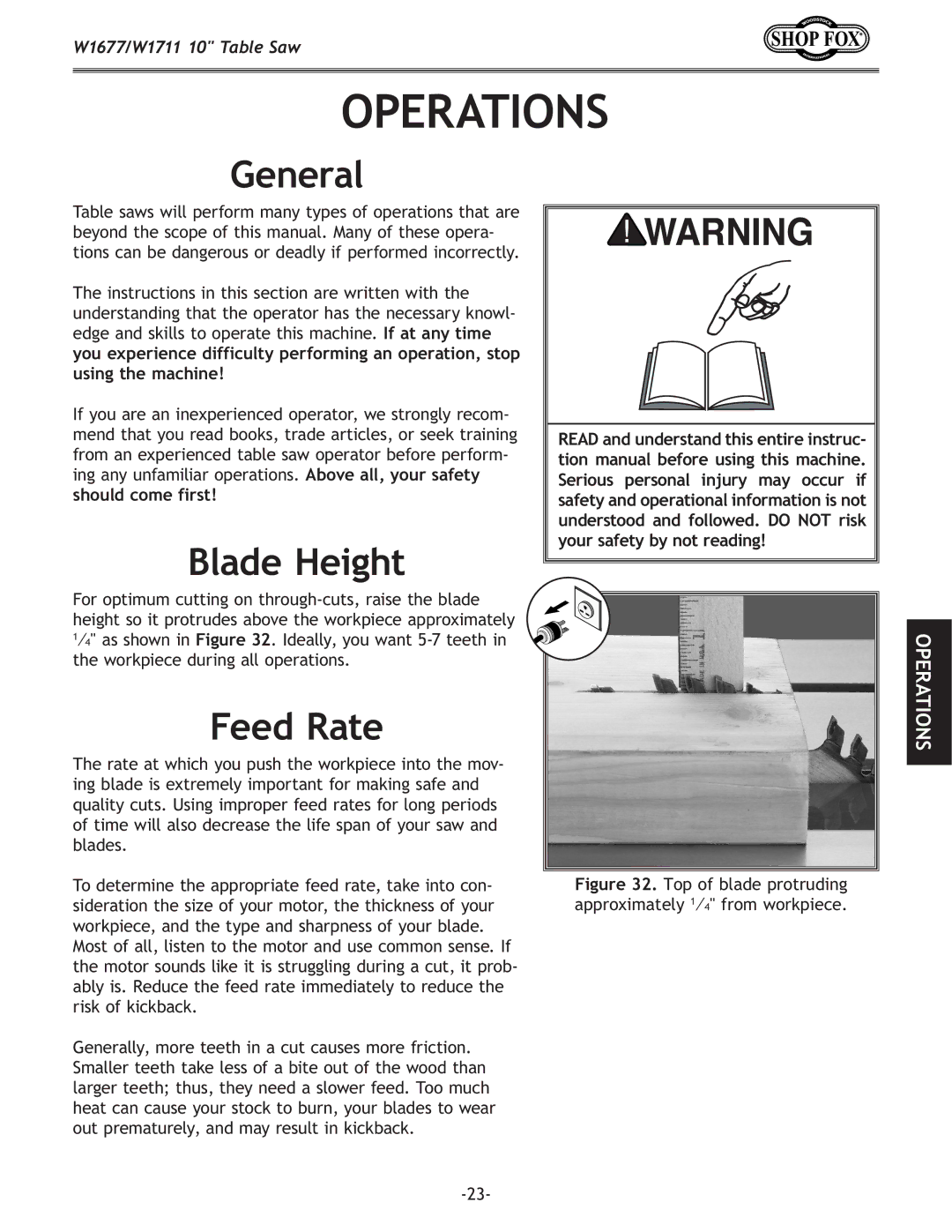

For optimum cutting on

Feed Rate

The rate at which you push the workpiece into the mov- ing blade is extremely important for making safe and quality cuts. Using improper feed rates for long periods of time will also decrease the life span of your saw and blades.

To determine the appropriate feed rate, take into con- sideration the size of your motor, the thickness of your workpiece, and the type and sharpness of your blade.

Most of all, listen to the motor and use common sense. If the motor sounds like it is struggling during a cut, it prob- ably is. Reduce the feed rate immediately to reduce the risk of kickback.

Generally, more teeth in a cut causes more friction. Smaller teeth take less of a bite out of the wood than larger teeth; thus, they need a slower feed. Too much heat can cause your stock to burn, your blades to wear out prematurely, and may result in kickback.

READ and understand this entire instruc- tion manual before using this machine. Serious personal injury may occur if safety and operational information is not understood and followed. DO NOT risk your safety by not reading!

Figure 32. Top of blade protruding approximately 1⁄4" from workpiece.

OPERATIONS