FORM

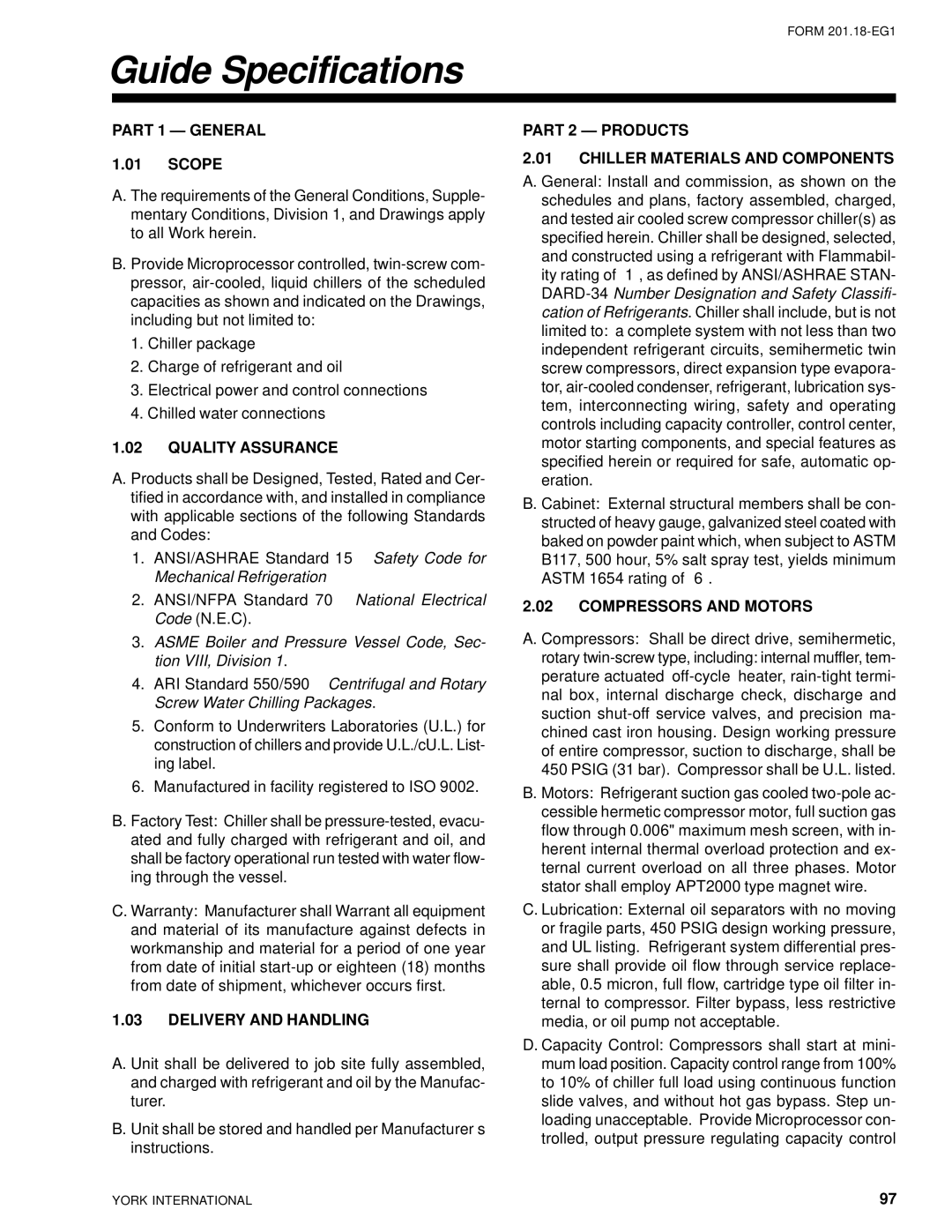

Guide Specifications

PART 1 — GENERAL

1.01SCOPE

A.The requirements of the General Conditions, Supple- mentary Conditions, Division 1, and Drawings apply to all Work herein.

B.Provide Microprocessor controlled,

1.Chiller package

2.Charge of refrigerant and oil

3.Electrical power and control connections

4.Chilled water connections

1.02QUALITY ASSURANCE

A.Products shall be Designed, Tested, Rated and Cer- tified in accordance with, and installed in compliance with applicable sections of the following Standards and Codes:

1.ANSI/ASHRAE Standard 15 – Safety Code for Mechanical Refrigeration

2.ANSI/NFPA Standard 70 – National Electrical Code (N.E.C).

PART 2 — PRODUCTS

2.01CHILLER MATERIALS AND COMPONENTS

A. General: Install and commission, as shown on the schedules and plans, factory assembled, charged, and tested air cooled screw compressor chiller(s) as specified herein. Chiller shall be designed, selected, and constructed using a refrigerant with Flammabil- ity rating of “1”, as defined by ANSI/ASHRAE STAN-

B. Cabinet: External structural members shall be con- structed of heavy gauge, galvanized steel coated with baked on powder paint which, when subject to ASTM B117, 500 hour, 5% salt spray test, yields minimum ASTM 1654 rating of “6”.

2.02COMPRESSORS AND MOTORS

3.ASME Boiler and Pressure Vessel Code, Sec- tion VIII, Division 1.

4.ARI Standard 550/590 – Centrifugal and Rotary Screw Water Chilling Packages.

5.Conform to Underwriters Laboratories (U.L.) for construction of chillers and provide U.L./cU.L. List- ing label.

6.Manufactured in facility registered to ISO 9002.

B.Factory Test: Chiller shall be

C.Warranty: Manufacturer shall Warrant all equipment and material of its manufacture against defects in workmanship and material for a period of one year from date of initial

1.03DELIVERY AND HANDLING

A. Unit shall be delivered to job site fully assembled, and charged with refrigerant and oil by the Manufac- turer.

B. Unit shall be stored and handled per Manufacturer’s instructions.

A. Compressors: Shall be direct drive, semihermetic, rotary

B.Motors: Refrigerant suction gas cooled

C.Lubrication: External oil separators with no moving or fragile parts, 450 PSIG design working pressure, and UL listing. Refrigerant system differential pres- sure shall provide oil flow through service replace- able, 0.5 micron, full flow, cartridge type oil filter in- ternal to compressor. Filter bypass, less restrictive media, or oil pump not acceptable.

D.Capacity Control: Compressors shall start at mini- mum load position. Capacity control range from 100% to 10% of chiller full load using continuous function slide valves, and without hot gas bypass. Step un- loading unacceptable. Provide Microprocessor con- trolled, output pressure regulating capacity control

YORK INTERNATIONAL | 97 |