FAN-ASSISTED COMBUSTION SYSTEM

An appliance equipped with an integral mechanical means to either draw or force products of combustion through the combustion chamber and/or heat exchanger.

SECTION VII: SAFETY CONTROLS

CONTROL CIRCUIT FUSE

A

Main power to the unit must still be interrupted at the main power disconnect switch before any service or repair work is to be done to the unit.

Blower and burner must never be operated without the blower panel in place.

LIMIT CONTROLS

There is a high temperature limit control located on the furnace vesti- bule panel near the control box. This is an automatic reset control that provides over temperature protection due to reduced airflow, that may be caused by a dirty filter, or if the indoor fan motor should fail.

INDOOR FAN SWITCH

The indoor fan motor is an operation controlled by normally open tem- perature actuated switch located above the limit control which is set to close at 110° F (43.3° C) and open at 90° F (32.2° C).

OIL BURNER PRIMARY CONTROL

The R7184A, B, P, U Interrupted Electronic Oil Primary is a line voltage, safety rated, interrupted ignition oil primary control for residential oil fired burners used in forced air furnaces. The R7184A, B, P, U used with a cad cell flame sensor operates an oil burner and optional oil valve. The primary controls fuel oil, senses flame, controls ignition spark and notifies a remote alarm circuit when in lockout.

The indicator light on the oil primary control provides lockout, recycle, and cad cell indications as follows:

1.Flashing at 1/2 second on, 1/2 second off: system is locked out or in restricted mode.

2.Flashing at 2 seconds on, 2 seconds off: control is in recycle

mode.

TABLE 11: Timings and Settings

3.On: cad cell is sensing flame.

4.Off: cad cell is not sensing flame.

Cad Cell Resistance Check

For proper operation, it is important that the cad cell resistance is below 1600 ohms. During a normal call for heat, once the control has entered the Run mode, press and release the reset button. See Table 10 for equivalent cad cell resistance.

TABLE 10: Cad Cell Resistance When Sensing Flame

Flashes | Cad Cell Resistance in Ohms |

1Less than 400

2More than 400 and less than 800

3More than 800 and less than 1600

4More than 1600 and less than 5000

Preliminary Steps

1.Check wiring connections and power supply.

2.Make sure power is on to controls.

3.Make sure limit control is closed.

4.Check contacts between ignitor and the electrodes.

5.Check the oil pump pressure.

6.Check the piping to the oil tank.

7.Check the oil nozzle, oil supply and oil filter.

Check Oil Primary Control

If the trouble is not in the burner or ignition hardware, check the oil pri- mary control by using the following equipment:

1.Screwdriver

2.Voltmeter (0 to 150 VAC range)

3.Insulated jumper wire with both ends stripped

4.Refer to the trouble shooting guide located after the wiring dia- grams to determine failure.

Electrical Shock Hazard

Can cause severe injury, death or property damage.

Be careful to observe all precautions to prevent electrical shock or equipment damage.

| Delay Timingsa |

|

| DIP Switch Settings |

| ||

Burner |

|

| |||||

(minutes) |

| ||||||

(seconds) |

|

|

| ||||

R7184U |

| R7184P |

|

| R7184U | R7184P | |

|

|

|

| ||||

|

|

|

|

|

|

|

|

0 | 0 |

| — | X | X | Off |

|

| 0 |

| 0.5 | Off | Off |

|

|

15 | 2 |

| 2 | Off | On | On | b |

4 |

| 4 | On | Off |

| ||

|

|

|

| ||||

| 5 |

| 8 | On | On |

|

|

X No Difference or | Impact |

|

|

|

|

|

|

aSpecific models may have different timings. Be sure to check device label.

b

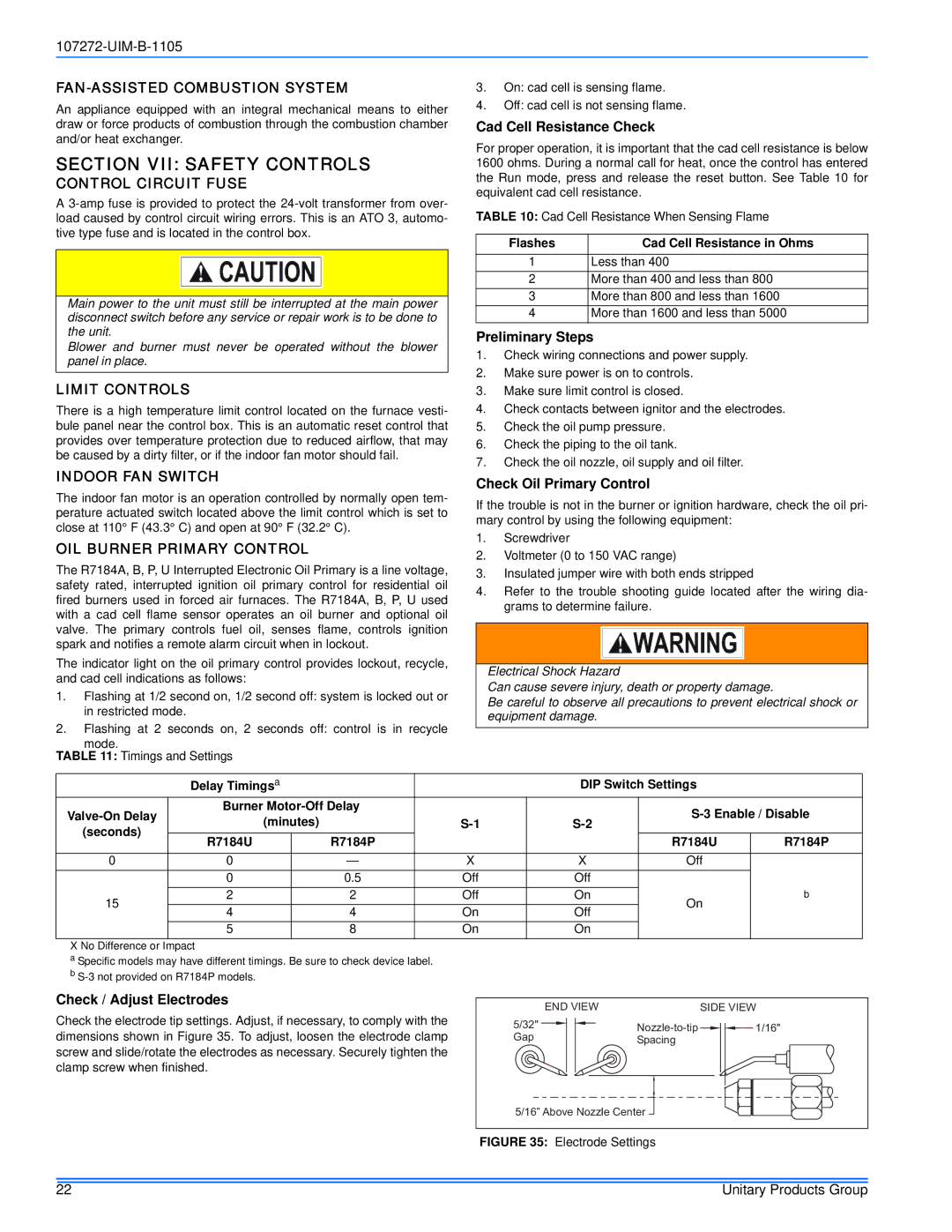

Check / Adjust Electrodes

Check the electrode tip settings. Adjust, if necessary, to comply with the dimensions shown in Figure 35. To adjust, loosen the electrode clamp screw and slide/rotate the electrodes as necessary. Securely tighten the clamp screw when finished.

| END VIEW | SIDE VIEW | |

5/32" | 1/16" | ||

Gap | |||

Spacing |

| ||

|

| ||

5/16” Above Nozzle Center |

| ||

FIGURE 35: Electrode Settings

22 | Unitary Products Group |