Support Services

Operations and Maintenance Courses

Each Operations and Maintenance Course first introduces the student to various bar code concepts and terminology. Topics include direct thermal/thermal transfer printing, continuous and non-continuous media, thin film thermal printheads, and serial and parallel communication interfaces. After completing this introductory material, the student focuses on printer setup and configuration. Each student sets up a printer, exercises its’ self-test diagnostics, and performs the preventive maintenance procedures required to insure trouble free operation. Mechanical and electrical operations are detailed through the disassembly and reassembly of the printer. Printer options including Cutter, Rewind, Twinax and Coax Interfaces, and memory expansion are installed and adjusted. Critical checks and alignments important to the proper operation of the printer such as media and ribbon sensor sensitivity, spindle maintenance and adjustments, printhead replacement and print quality alignments are discussed and performed by our students. Troubleshooting techniques and common faults are described and reviewed through hands-on exercises. To assist in troubleshooting communications related problems an introduction to the Zebra Programming Language (ZPL® and ZPL II®) is provided. Students review the general structure of ZPL and then interface computers to the Zebra printers and follow a series of exercises which lead them through the steps necessary create and print labels.

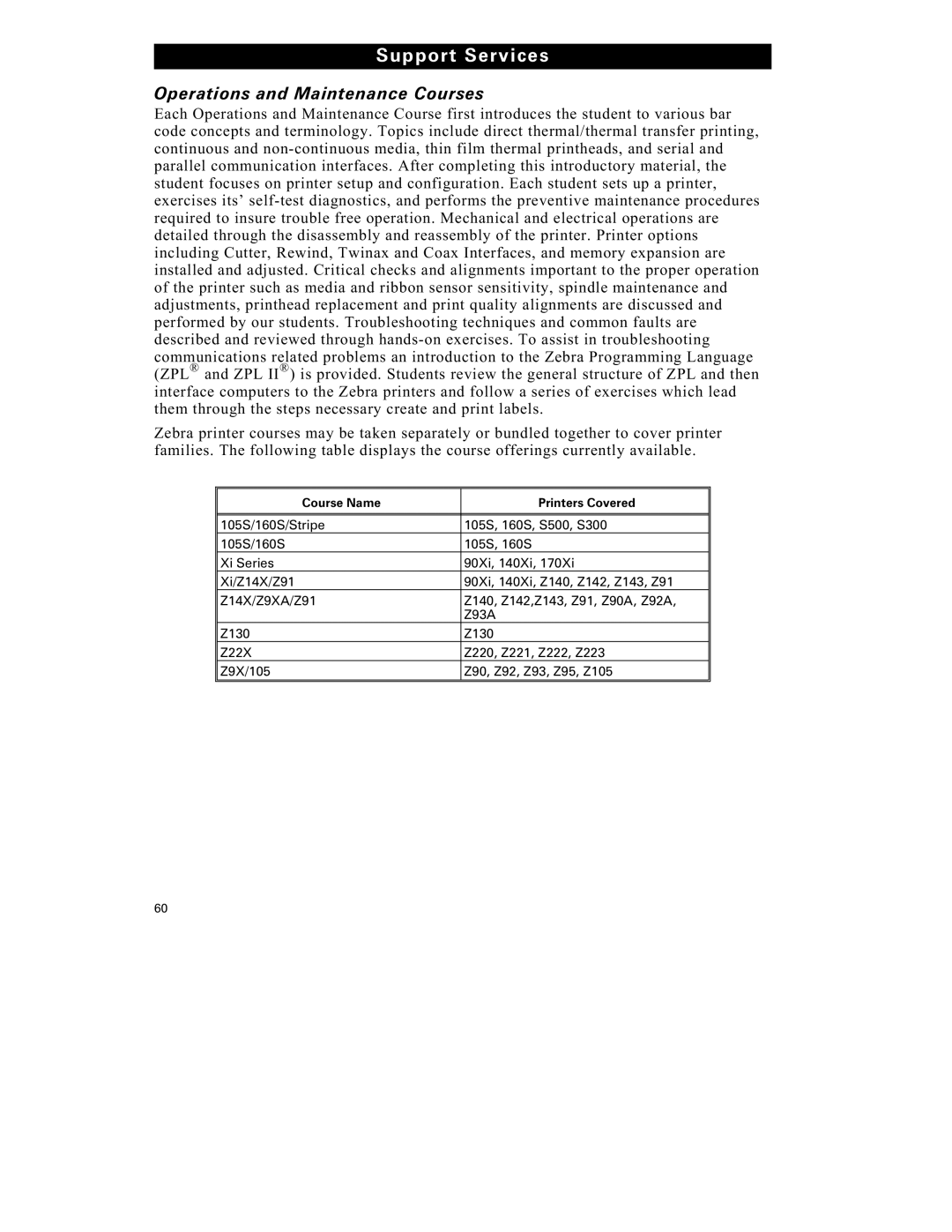

Zebra printer courses may be taken separately or bundled together to cover printer families. The following table displays the course offerings currently available.

Course Name | Printers Covered |

| |

105S/160S/Stripe | 105S, 160S, S500, S300 |

105S/160S | 105S, 160S |

Xi Series | 90Xi, 140Xi, 170Xi |

Xi/Z14X/Z91 | 90Xi, 140Xi, Z140, Z142, Z143, Z91 |

Z14X/Z9XA/Z91 | Z140, Z142,Z143, Z91, Z90A, Z92A, |

| Z93A |

Z130 | Z130 |

Z22X | Z220, Z221, Z222, Z223 |

Z9X/105 | Z90, Z92, Z93, Z95, Z105 |