9. DISASSEMBLY AND ASSEMBLY

(1)Be sure to remember the locations of individual parts when disassembling the generator so that the generator can be reassembled correctly. Tie tags with the necessary information written in to facilitate easier and smoother reassembly.

(2)For more convenience, group the related parts and store them in the same box.

(3)To prevent bolts and nuts from being misplaced or installed incorrectly, place them temporarily at their original positions.

(4)Handle the disassembled parts with care and clean them before reassembly using neutral cleaning oil. (Be careful not to clean electric parts with neutral cleaning oil.)

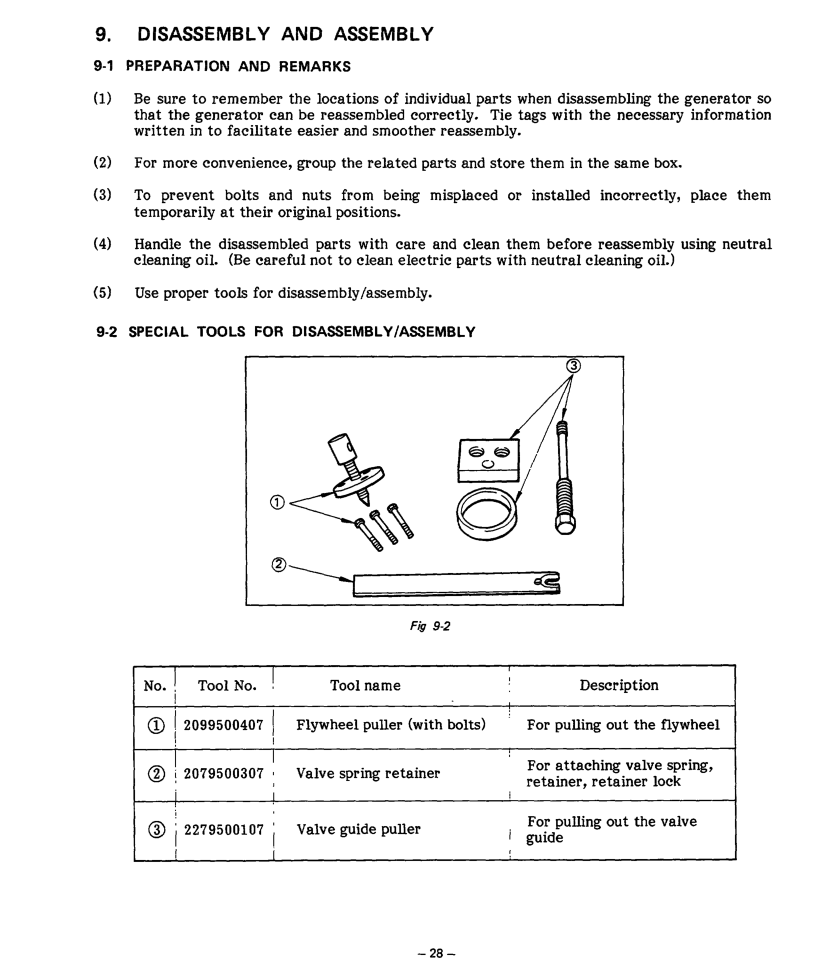

(5)Use proper tools for disassembly/assembly.

Fig

No. | i | Tool No. ! | Tool name |

| Description |

| I | 2099500407 1 | Flywheel puller (with bolts) |

| For pulling out the flywheel |

| ! |

|

|

| |

@ | 12079500307 i | Valve spring retainer |

| For attaching valve spring, | |

| retainer, retainer lock | ||||

|

|

|

|

| |

| I |

|

|

| For pulling out the valve |

|

| 2279500107 I | Valve guide puller |

| |

|

| i | guide | ||

|

|

|

| ||

|

| I |

| , |

|

|

|

|

|

| |

- 28 -