Application and Function

Power Supply Interruption

The following table shows reactions to the changes in operating voltage:

Voltage level | Reaction of the controller |

|

|

19.3 to 28.8 VDC | Normal operation |

|

|

< 18.0 VDC | Alarm state (internal variables are written and put to the inputs/ |

| outputs). |

|

|

< 12.0 VDC | Inputs and outputs are switched off. |

|

|

If power supply is interrupted, all inputs and outputs discontinue and return to the off "safe" state.

Small System A Safety PLC can be reconfigured while the network is executing an existing Reconfiguration configuration. Resources which require configuration must be stopped. The following table describes the reconfiguration procedure:

Step | Action |

1Using the XPSMFWIN programming environment, stop the Safety PLC’s system which requires the new configuration.

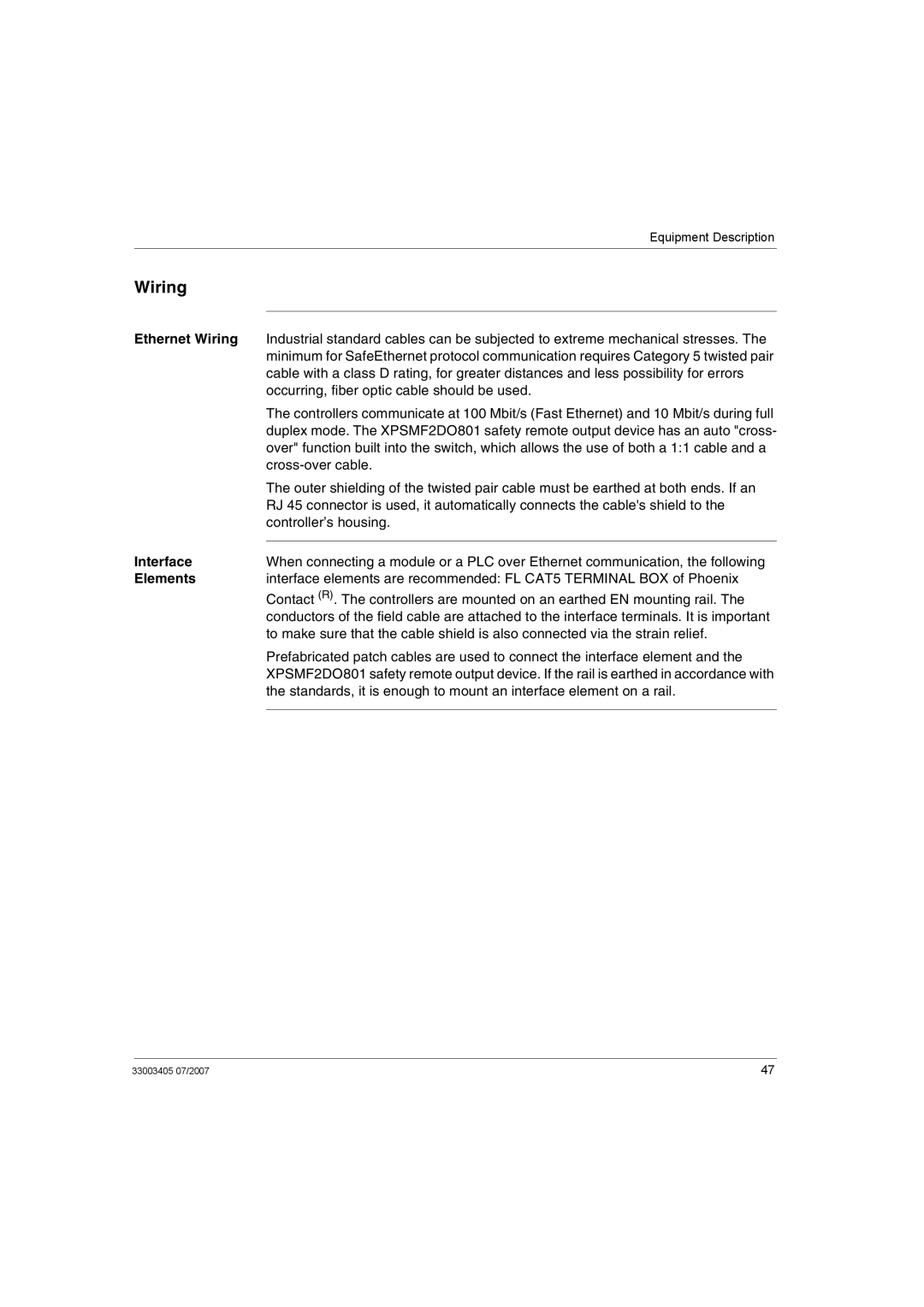

2Download the new configuration fully checked by a qualified safety engineer to the Safety PLC via Ethernet cable Cat 5, grade D or better.

3Once the module is

4Execute the new configuration immediately.

Large System Reconfiguration

The following table describes the reconfiguration procedure for large systems:

Step | Action |

1Stop the relevant resources within the network using the XPSMFWIN programming environment. Small segments of a network can be reconfigured in stages.

2Connect your PC to any Ethernet communications point.

3Download the new configuration(s) fully checked by a qualified safety engineer to the Safety PLC network via Ethernet cable Cat 5, grade D or better.

4Restart all devices, preferably in stages - system by system.

30 | 33003405 07/2007 |