|

| ACCESSORIES | ||||

|

|

|

| |||

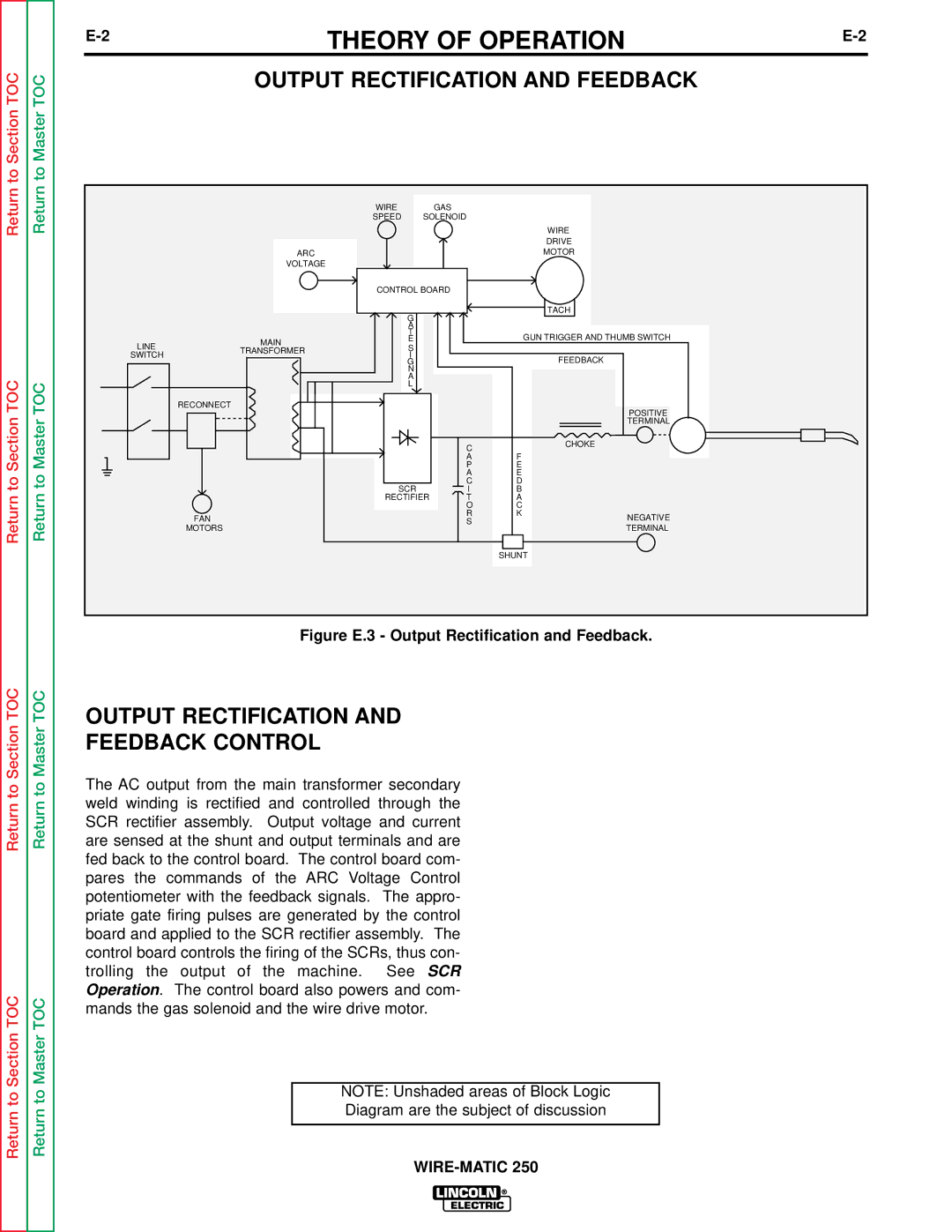

TOC | TOC | SPOOL GUN MODULE BOARD |

| 5. | Position the Spool Gun Module Board over the | |

INSTALLATION |

|

| ||||

Section | Master |

|

|

| tors at the top. |

|

for use with | 6. | Gently press the board onto the fasteners, making | ||||

|

| NOTE: The |

|

|

| |

to | to | 9900. Model Codes below 9900 may be used with |

| sure all the fasteners snap into place. |

| |

|

|

| ||||

Return | Return | addition of holes to the case as described in the instal- | 7. Remove the | |||

|

| |||||

|

| lation instructions below. |

| |||

|

|

|

| connector on the wire drive side of the machine to | ||

|

|

|

|

| ||

|

|

|

|

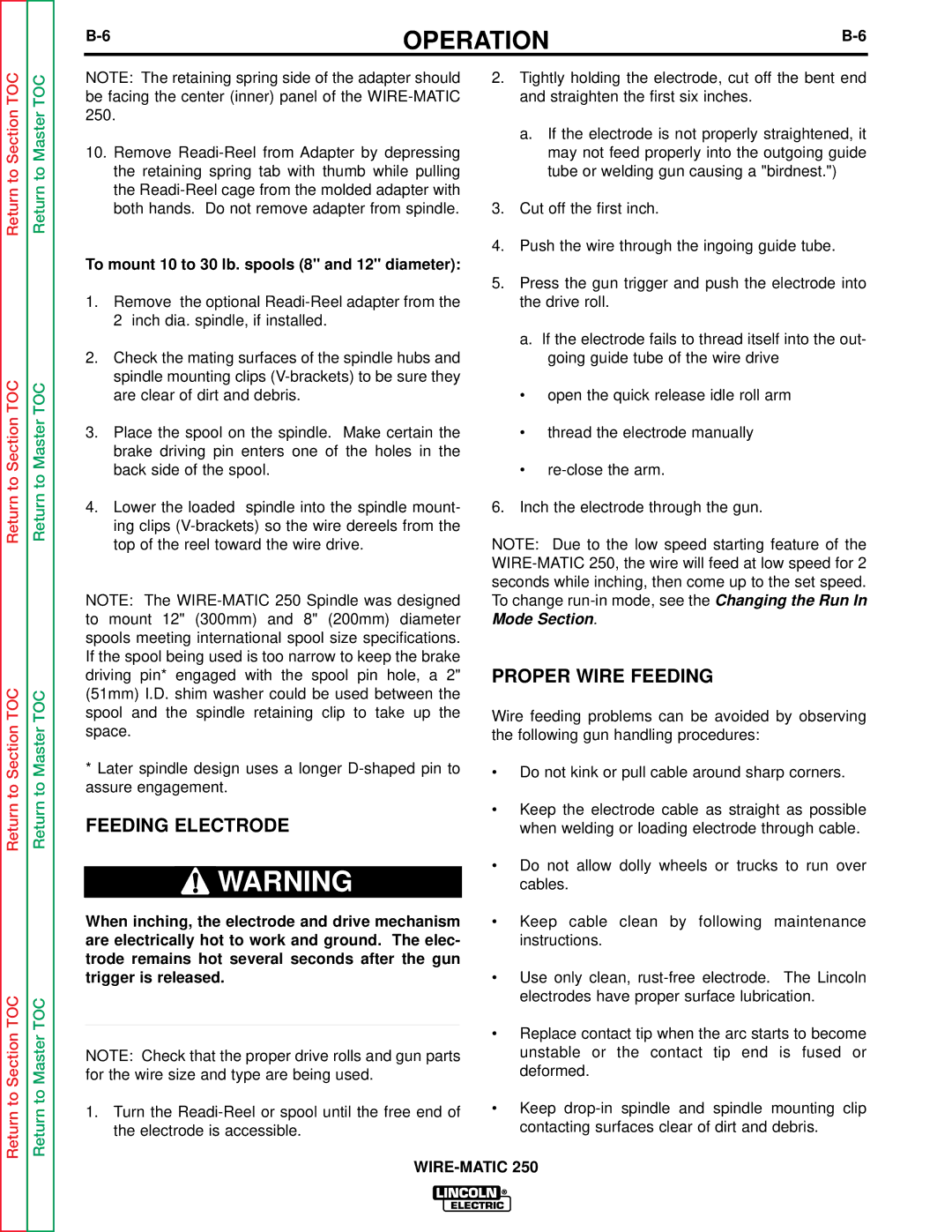

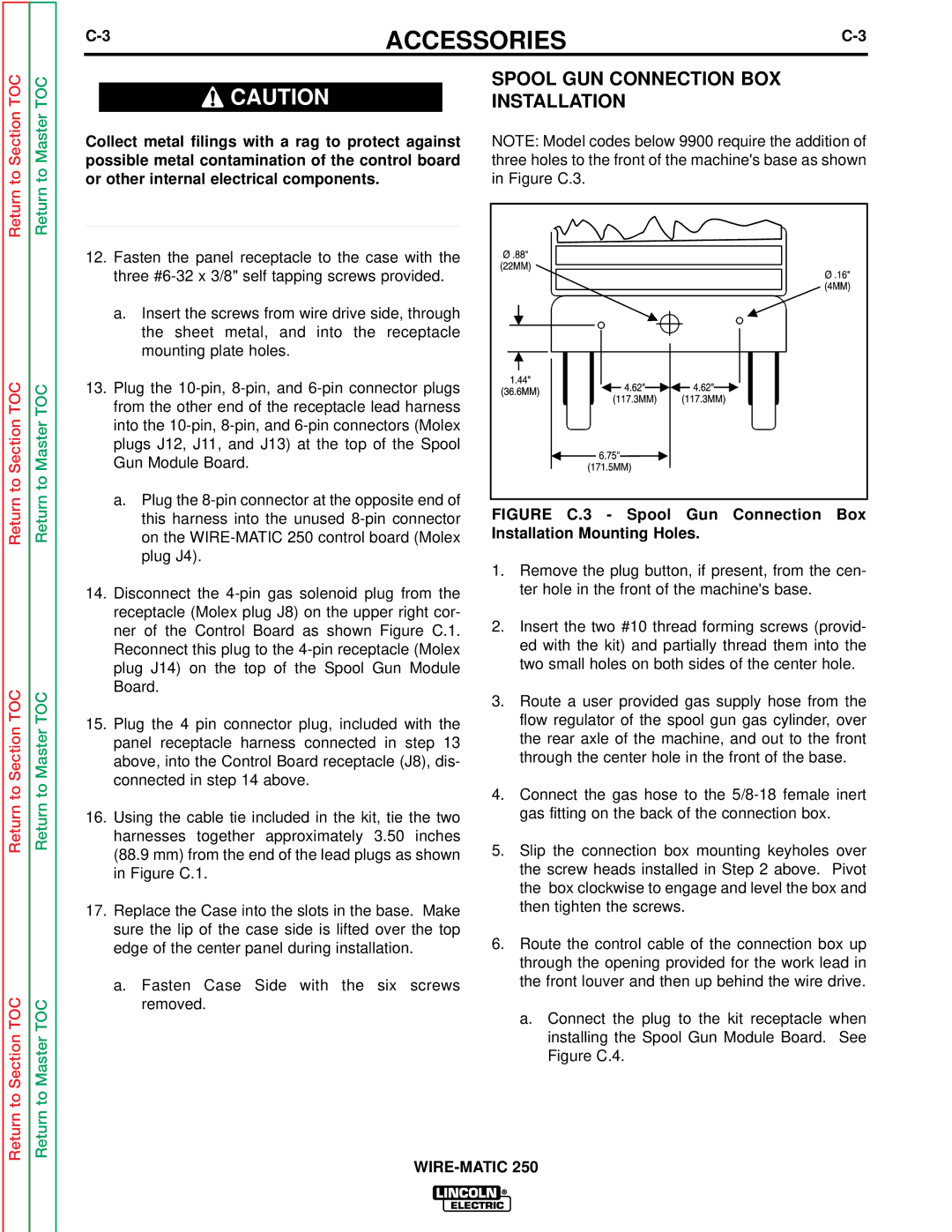

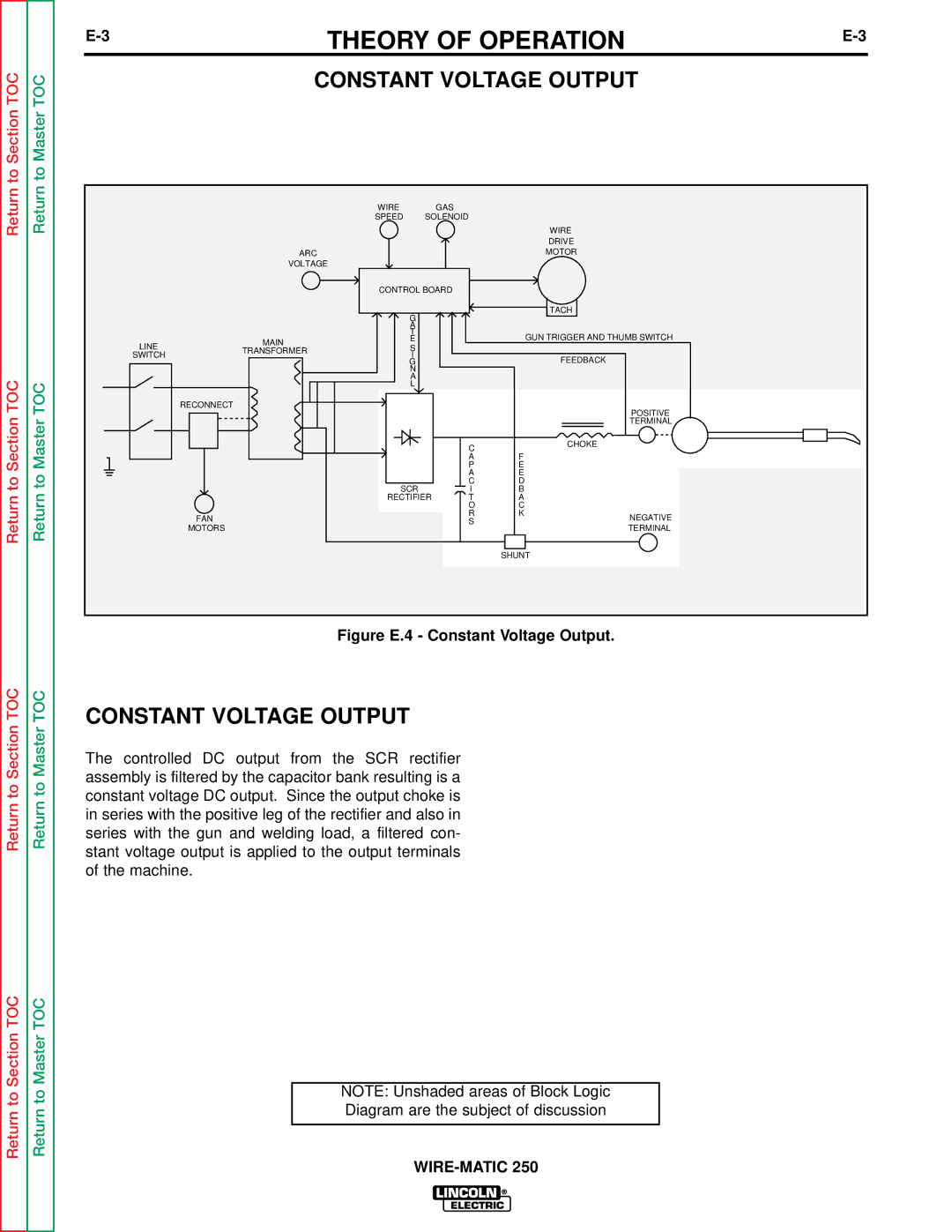

| release the small metal cover. See Figure C.2. | |

![]() WARNING

WARNING

Do not operate with covers removed. Disconnect AC input power before servicing. Do not touch electrically live parts. Only qualified electricians should install, use. or service this equipment.

TOC | TOC | ____________________________________ | |

Sectionto | Masterto | 1. | Disconnect AC input power to the machine before |

|

| ||

|

|

| installing the Spool Gun Module Board. |

Return | Return | 2. | Remove the six screws from the Left Case Side |

| and Door and Hinge Assembly. | ||

|

|

| |

3.Lift the Left Case Side and Door and Hinge Assembly up and over the lip of the center divider panel while pulling the case side away from the unit. Slide it out of the slots in the base.

|

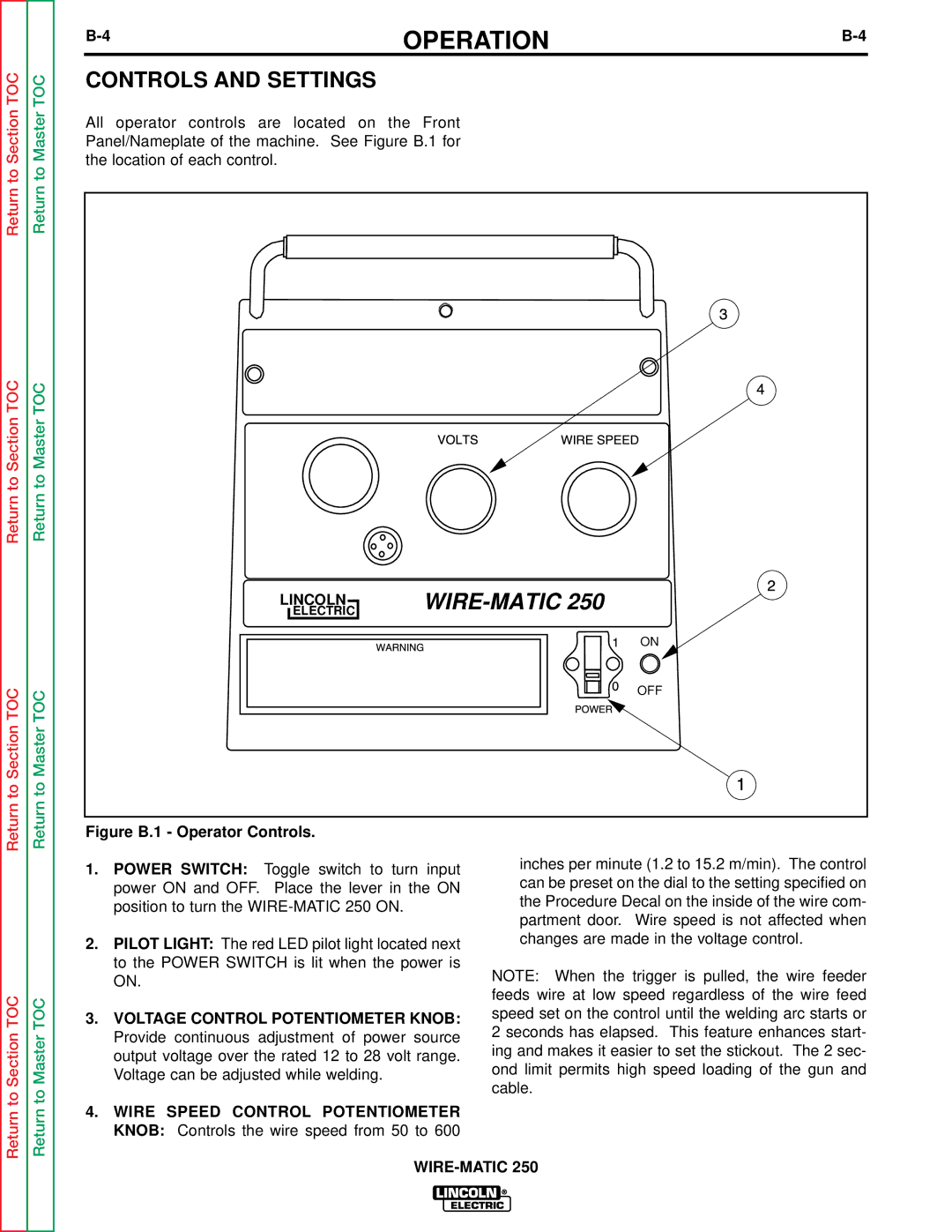

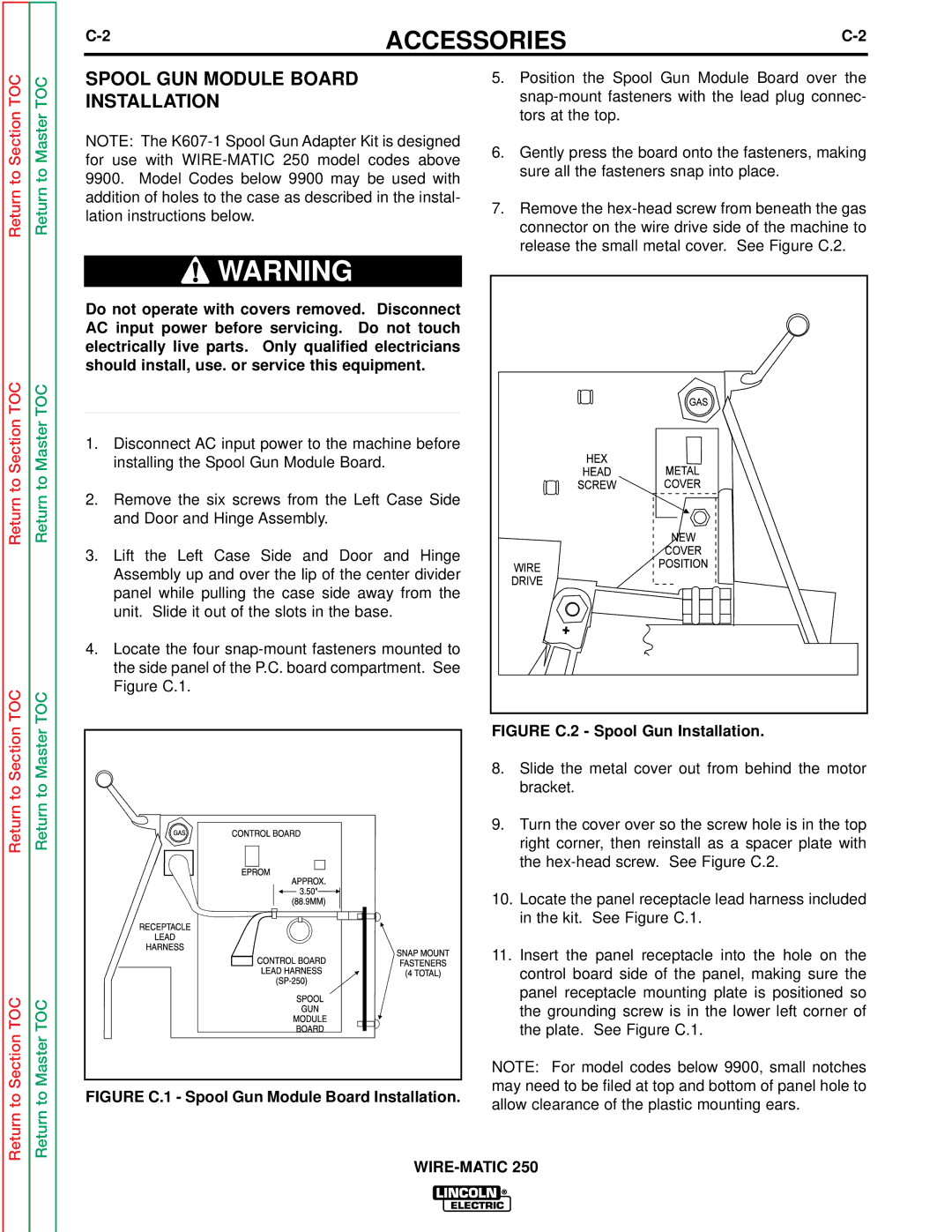

| 4. Locate the four |

|

| |

|

| the side panel of the P.C. board compartment. See |

|

| |

TOC | TOC | Figure C.1. |

|

| |

| FIGURE C.2 - Spool Gun Installation. | ||||

Section | Master |

| |||

| 8. | Slide the metal cover out from behind the motor | |||

|

|

| |||

to | to |

|

| bracket. | |

|

|

| |||

Return | Return |

| 9. | Turn the cover over so the screw hole is in the top | |

|

|

| |||

|

|

|

| right corner, then reinstall as a spacer plate with | |

|

|

|

| the | |

|

|

| 10. | Locate the panel receptacle lead harness included | |

|

|

|

| in the kit. See Figure C.1. | |

|

|

| 11. | Insert the panel receptacle into the hole on the | |

|

|

|

| control board side of the panel, making sure the | |

TOC | TOC |

|

| panel receptacle mounting plate is positioned so | |

|

| the grounding screw is in the lower left corner of | |||

|

|

|

| ||

Section | Master |

|

| the plate. See Figure C.1. | |

| NOTE: For model codes below 9900, small notches | ||||

|

|

| |||

to | to | FIGURE C.1 - Spool Gun Module Board Installation. | may need to be filed at top and bottom of panel hole to | ||

allow clearance of the plastic mounting ears. | |||||

| |||||

Return | Return |

| |||

| |||||

|

| ||||