Section 3 — Operation

4.Connect a frequency meter across the generators AC output leads.

5.Turn the primary adjust screw to obtain a fre- quency reading of 61.5 Hertz. Turn the secondary adjust screw to obtain a frequency of 62.5 Hz.

6.When frequency is correct at no load, check the AC voltage reading. If voltage is incorrect, the volt- age regulator may require adjustment (See the Voltage Regulator Adjustment section).

2.7.2 13 KW AND 16 KW UNITS

NOTE:

The access panel on top of the control panel must be removed to adjust the voltage regulator.

NOTE:

The voltage regulator is housed above the gen- erator's control panel. The regulator maintains a voltage in direct proportion to frequency at a

1ratio. For example, at 62 Hertz,

NOTE:

All

3.1USING THE AUTO/OFF/MANUAL SWITCH (FIGURE 3.1)

2.7.3 ADDITIONAL CORROSION PROTECTION

Periodically spray all engine linkage parts and brack- ets with corrosion inhibiting spray such as

3.1.1 “AUTO” POSITION

Selecting this switch position activates fully automatic system operation. It also allows the unit to automati- cally start and exercise the engine every seven days with the setting of the exercise timer (see the Setting the Exercise Timer section).

2.8VOLTAGE REGULATOR ADJUSTMENT

2.8.1 7KW UNITS

With the frequency between

2.8.2 10, 13, AND 16KW UNITS

With the frequency between

Figure 2.3 – Voltage Adjustment Potentiometer

Turn to

adjust voltage.

3.1.2 “OFF” POSITION

This switch position shuts down the engine. This position also prevents automatic operation.

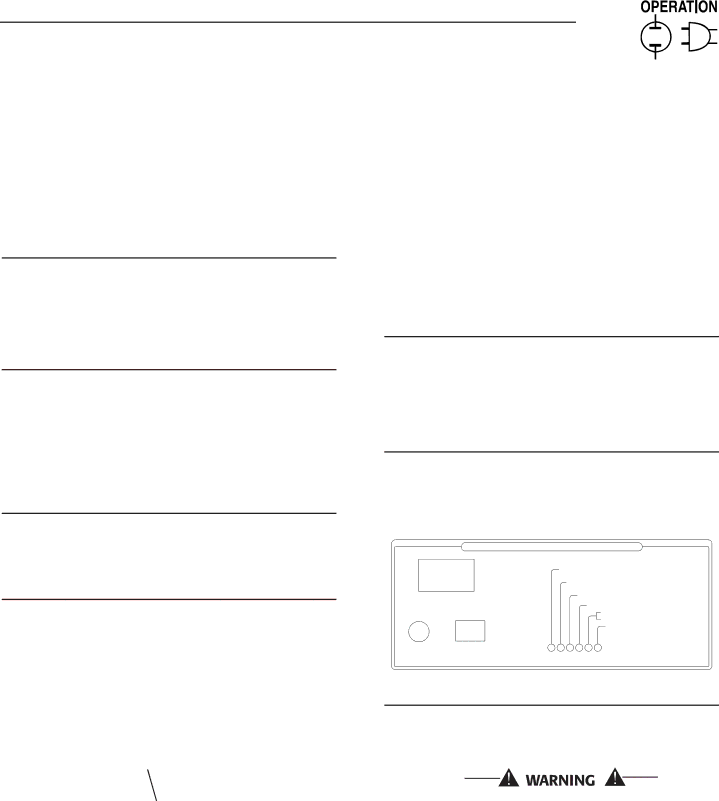

Figure 3.1 – Generator Control Panel

CONTROL AND INFORMATION CENTER

SYSTEM SET

LOW BATTERY

LOW OIL

AUTO. OFF MAN.

HIGH TEMP

SYSTEM FUSEOVER SPEED

NO RPM SENSE IF FLASHING OVER CRANK

15A | SET | FLASHING GREEN LED= | |

NO UTILITY SENSE | |||

ASSY: 0F8418/0F8419 | EXERCISE | 5 FLASHING RED LEDS= | |

TIME | EXERCISER NOT SET | ||

|

3.1.3 “MANUAL” POSITION

Set the switch to MANUAL to crank and start the engine. Transfer to standby power will not occur unless there is a utility failure.

With the switch set to AUTO, the engine may crank and start at any time without warning. Such automatic starting normally occurs when utility power source voltage drops below a pre- set level or during the normal exercise cycle. To prevent possible injury that might be caused by such sudden starts, always set the switch to OFF and remove the fuses before working on or around the generator or transfer switch. Then, place a “DO NOT OPERATE” tag on the genera- tor panel and on the transfer switch.

15